Precise docking device and method for frame type detection mechanism and cabin body

A technology of detection mechanism and docking device, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easily bumped products and high labor intensity, and achieve the effect of convenient docking operation, reduced labor intensity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

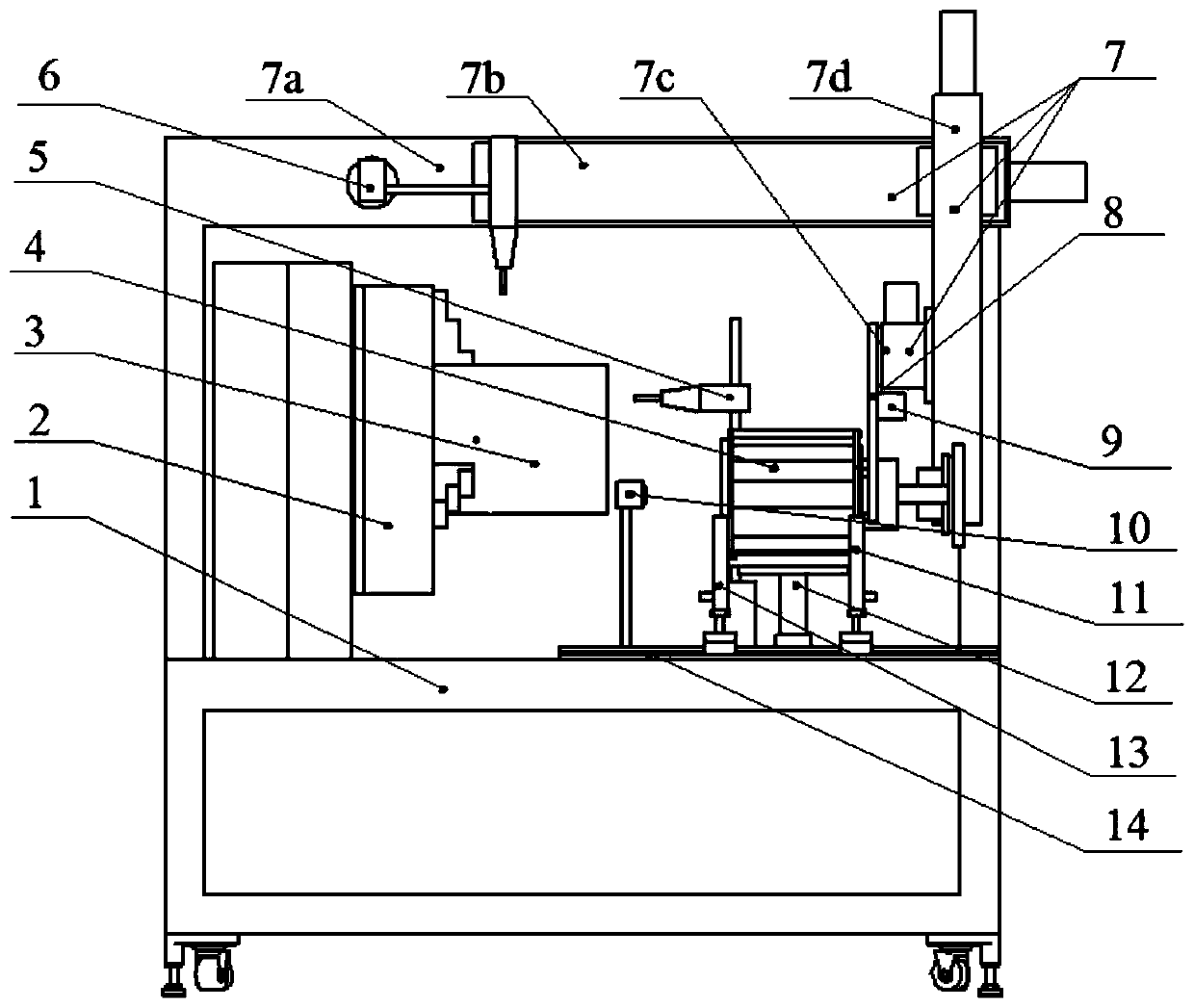

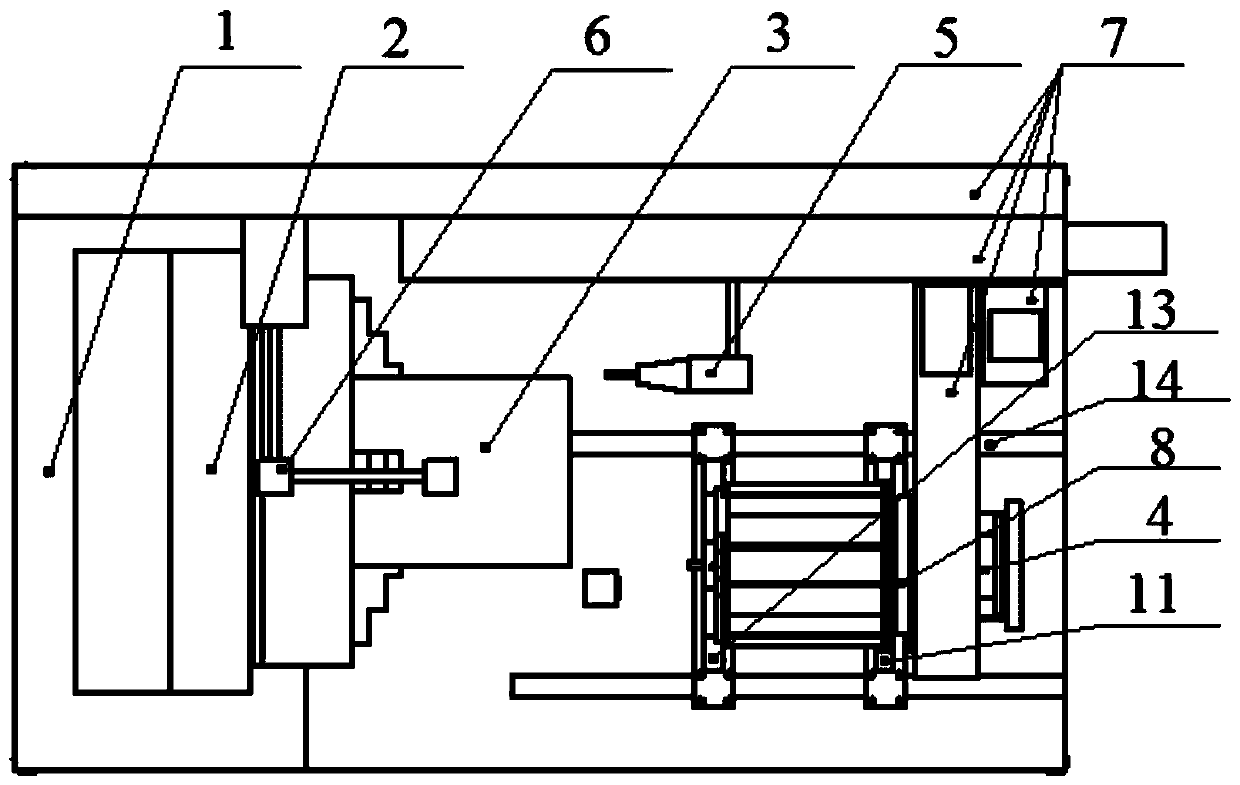

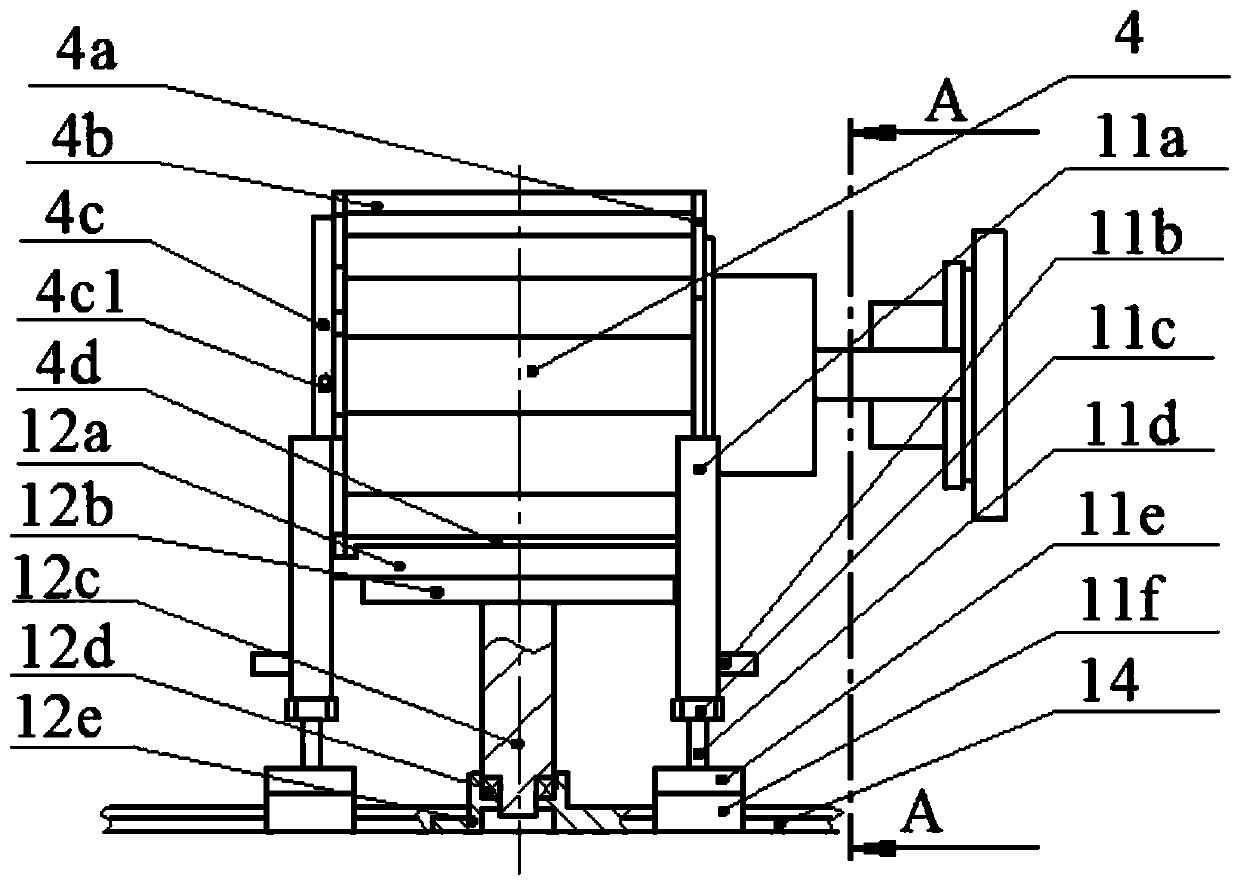

[0044] The invention mainly solves the problem of docking between the frame-type detection mechanism and the cabin body. The frame-type detection mechanism is composed of a front end cover, a rear end cover and 2 to 4 side plates to form a frame, and various microwave boxes are installed inside. Servos and antennas. When the frame-type detection mechanism is docked with the cabin, the entire frame part needs to be installed in the cabin, and the positioning is realized through the alignment of the pin holes on the front cover with the pins on the cabin and the contact between the front cover and the installation surface of the cabin. The multiple axial mounting holes on the top and the multiple ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com