Multi-head glue spraying device for sand mold casting

A sand mold, multi-head technology, applied in the field of mold casting, can solve the problems of colloid concentration and difficult dispersion, insufficient local glue application, low work efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

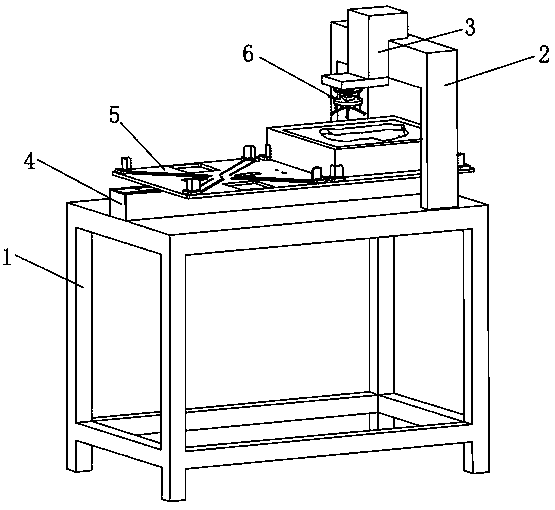

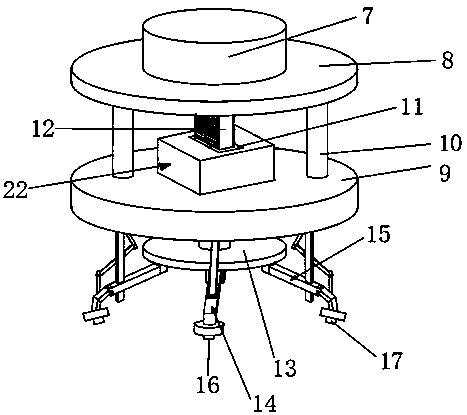

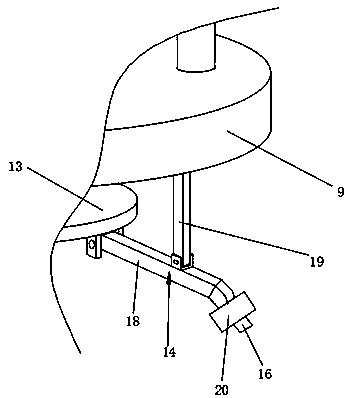

[0026]Embodiment: a kind of multi-head glue spraying device for sand mold casting, such as Figure 1-7 As shown, it includes a frame 1, the frame 1 is provided with a gantry frame 2, the gantry frame 2 is provided with a sliding block 3, the frame 1 is provided with a linear conveying slide 4, and the linear conveying slide 4 4 is provided with a sand box positioning frame 5, the bottom of the sliding block 3 is provided with a multi-head glue spraying mechanism 6, and the multi-head glue spraying mechanism 6 includes a rotating seat 7 arranged at the bottom of the sliding block 3, and the bottom of the rotating seat 7 is provided with an upper The base plate 8 is provided with a lower base plate 9 below the upper base plate 8, and a plurality of positioning rods 10 are arranged between the upper base plate 8 and the lower base plate 9; the middle part of the lower base plate 9 is provided with a vertically downward travel sleeve 11, The stroke sleeve 11 is provided with a mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com