Low-friction labor-saving drain valve lifting mechanism and drain valve thereof

A lifting mechanism and drainage valve technology, applied in water supply devices, flushing equipment with water tanks, buildings, etc., can solve problems such as low friction and labor saving, and achieve the effects of reducing friction, reducing failure rate and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

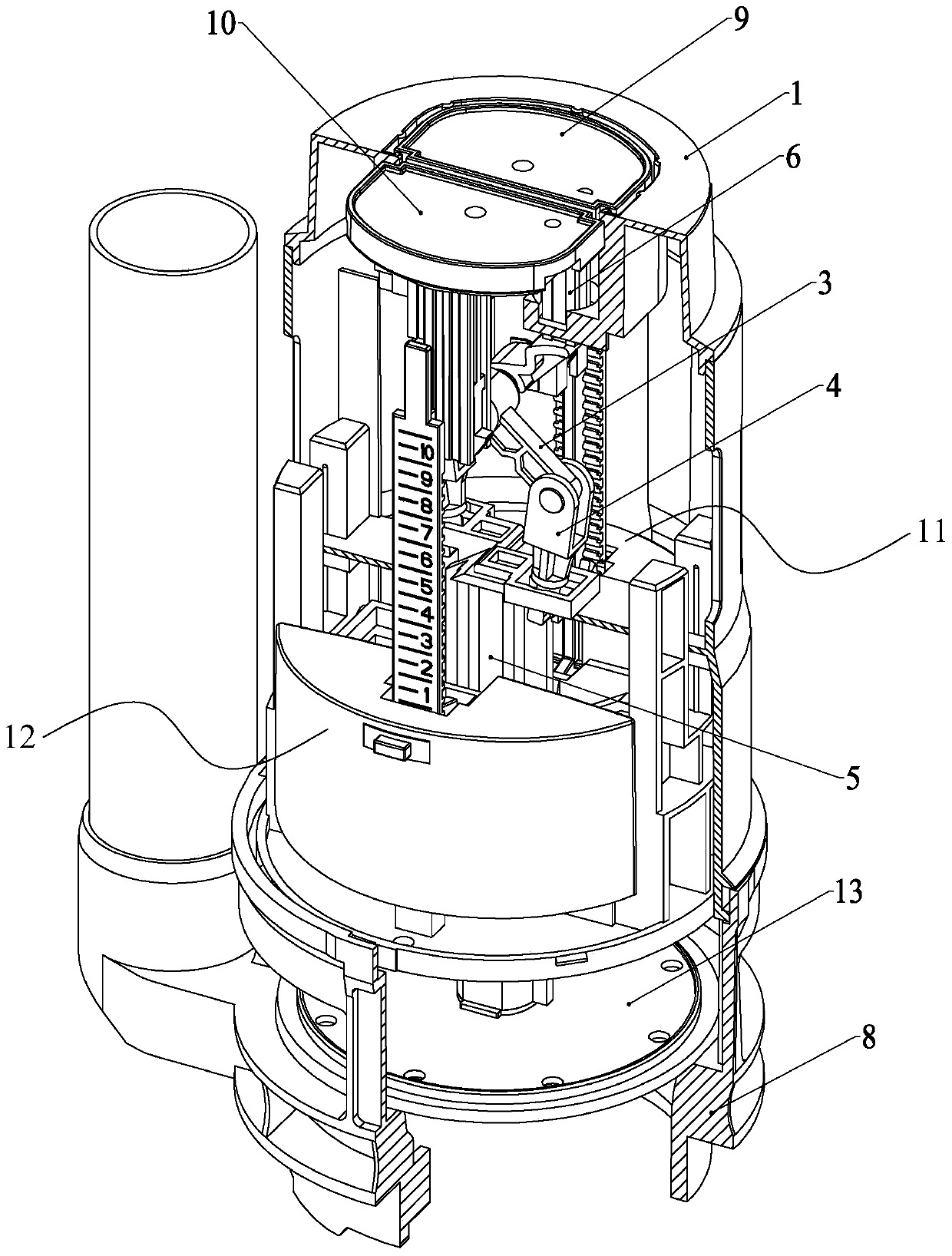

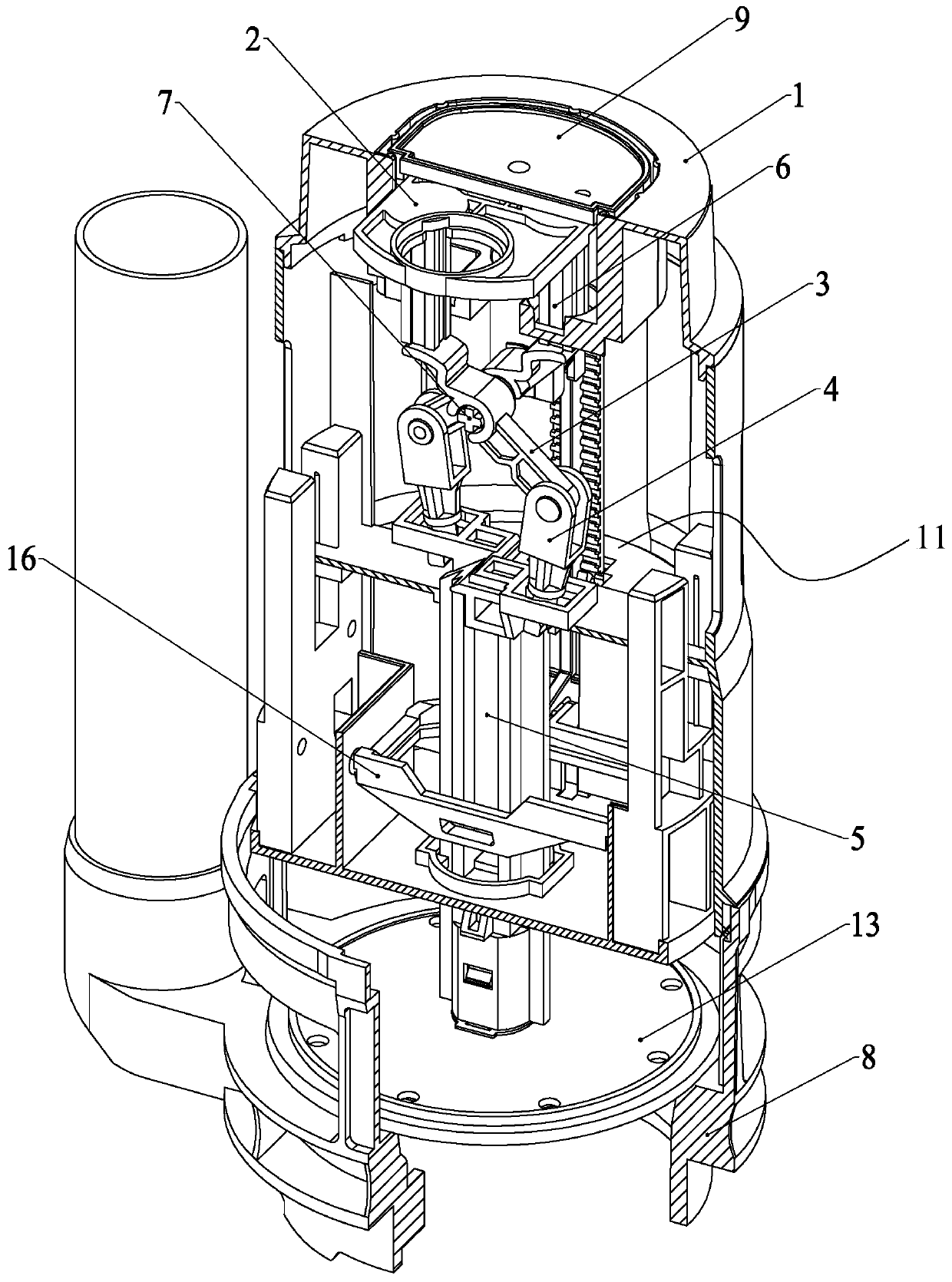

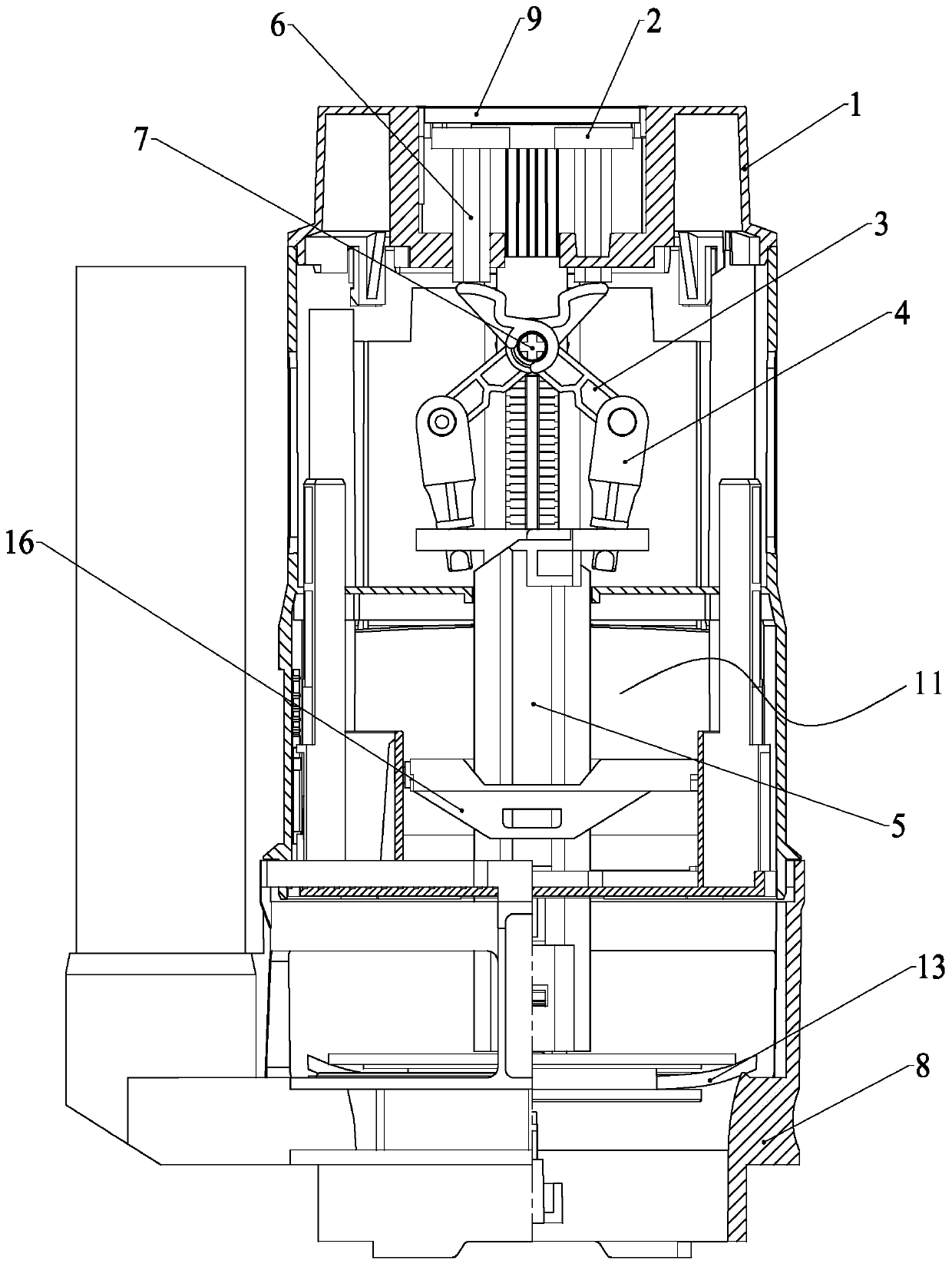

[0026] refer to Figure 1 to Figure 14 , this embodiment is a double-row button drain valve using a low-friction and labor-saving lifting mechanism. The button seat 1 is installed on the drain valve body, and the drain valve body is provided with a half row that cooperates with the lifting mechanism to drain and close the water. The buoy assembly 11 and the full row of buoy assemblies 12; the lifting mechanism includes a half row of buttons 9, a full row of buttons 10, a driver 2, a support swing arm 3, a pull rod 4 and a pull rod 5; the driver is installed on the half row of buttons arranged side by side And the lower side of the whole row of buttons, the driving part is downwardly formed with two pressing rods 6; there are two supporting swing arms, and the two supporting swing arms are hinged with the same horizontal axis 7 of the button seat to form an X-shaped support structure, each The upper ends of the supporting swing arms are respectively supported and connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com