Preparation method of durable hydrophilic polypropylene non-woven fabric

A technology of non-woven fabrics and polypropylene, applied in the field of polypropylene non-woven fabrics, can solve the problems of poor hydrophilicity and durability of non-woven fabrics, and achieve the effects of easy promotion and use, low equipment requirements, and simple operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

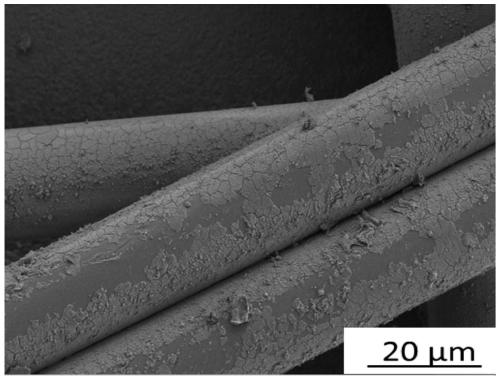

[0023] (1) Preparation of hydrophilic finishing agent: dopamine hydrochloride, CuSO 4 and H 2 o 2 Dissolve in Tris buffer and stir evenly, then add silica sol with a particle size of 20nm and a solid content of 20%, and adjust the pH of the solution to 8.5 to obtain a hydrophilic finishing agent;

[0024] (2) Wetting pretreatment of nonwovens: Wet polypropylene spunbond nonwovens in absolute ethanol for 1 min and then take them out;

[0025] (3) Hydrophilic finishing of nonwovens: Soak the wetted polypropylene nonwoven fabric in the prepared hydrophilic finishing agent for 3 minutes, take it out, and roll it on a padding machine to control the excess rate of 90%. Then place it in an air-blast oven at 80°C and bake for 20 minutes. After drying, a hydrophilic polypropylene nonwoven fabric is obtained.

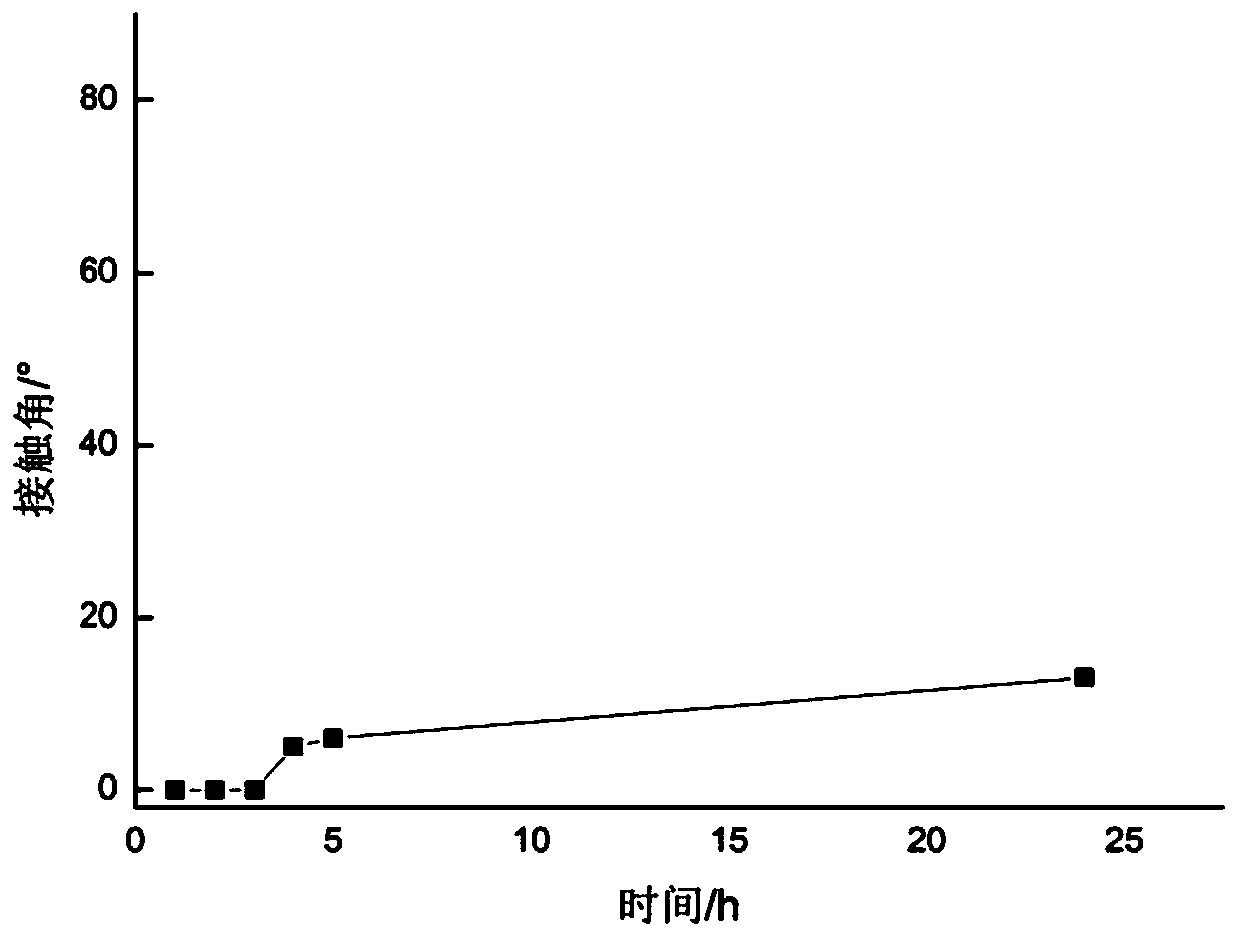

[0026] After testing, the water contact angle of the prepared hydrophilic polypropylene nonwoven fabric is 0° (keep for 5s after dripping water and then test); take two 5 × 5c...

Embodiment 2

[0028] (1) Preparation of hydrophilic finishing agent: dopamine hydrochloride, CuSO 4 and H 2 o 2 Dissolve in Tris buffer and stir evenly, then add silica sol with a particle size of 40nm and a solid content of 30%, and adjust the pH of the solution to 8.5 to obtain a hydrophilic finishing agent;

[0029] (2) Wetting pretreatment of nonwovens: Wet polypropylene spunbonded nonwovens in isopropanol for 1 minute and then take them out;

[0030] (3) Hydrophilic finishing of nonwoven fabrics: Soak the wetted polypropylene nonwoven fabric in the prepared hydrophilic finishing agent for 3 minutes, take it out, and roll it on a padding machine to control the excess rate of 95%. Then place it in an air-blast oven at 80°C and bake for 20 minutes. After drying, a hydrophilic polypropylene nonwoven fabric is obtained.

[0031] After testing, the water contact angle of the prepared hydrophilic polypropylene nonwoven fabric is 0° (keep for 5s after dripping water and then test); take two...

Embodiment 3

[0033] (1) Preparation of hydrophilic finishing agent: dopamine hydrochloride, CuSO 4 and H 2 o 2 Dissolve in Tris buffer and stir evenly, then add silica sol with a particle size of 30nm and a solid content of 20%, and adjust the pH of the solution to 8.5 to obtain a hydrophilic finishing agent;

[0034] (2) Wetting pretreatment of nonwovens: Wet polypropylene spunbond nonwovens in 95% industrial ethanol for 1 min and then take them out;

[0035] (3) Hydrophilic finishing of nonwovens: Soak the wetted polypropylene nonwoven fabric in the prepared hydrophilic finishing agent for 3 minutes, take it out and roll it on a padding machine, and control the excess rate to 100%. Then place it in an air-blast oven at 80°C and bake for 20 minutes. After drying, a hydrophilic polypropylene nonwoven fabric is obtained.

[0036] After testing, the water contact angle of the prepared hydrophilic polypropylene nonwoven fabric is 0° (keep for 5s after dripping water and then test); take tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com