Fully-automatic intelligent sand screening machine used for construction site

A construction site, fully automatic technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problem of single sand size, can not meet the sand particle gradation, etc., to achieve accurate particle size, reduce the amount of manual cleaning, strong and practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

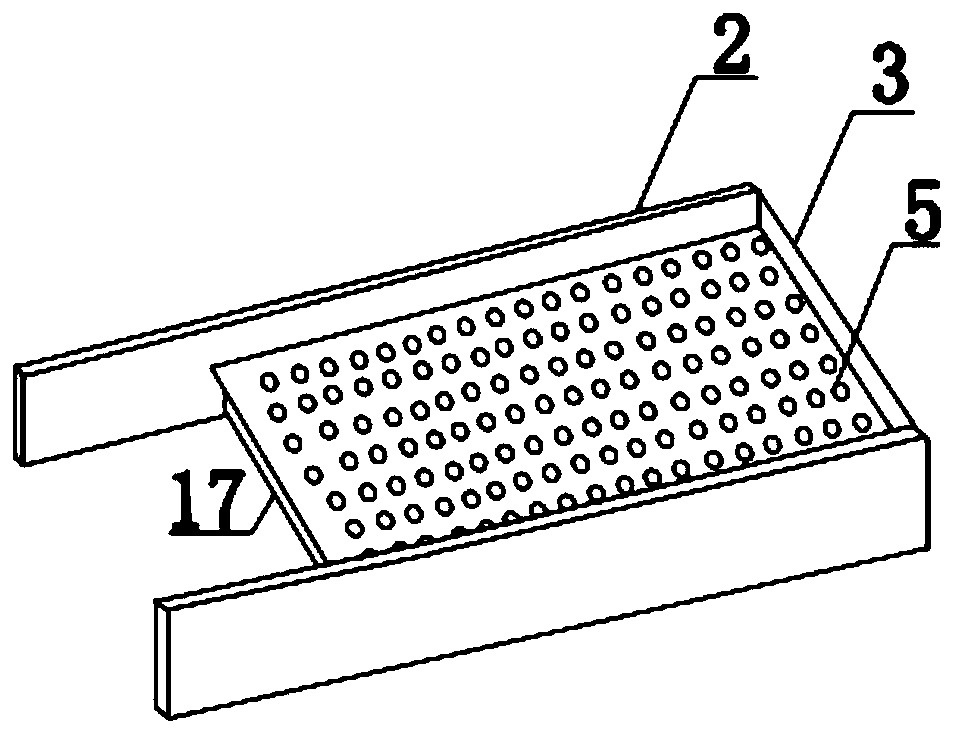

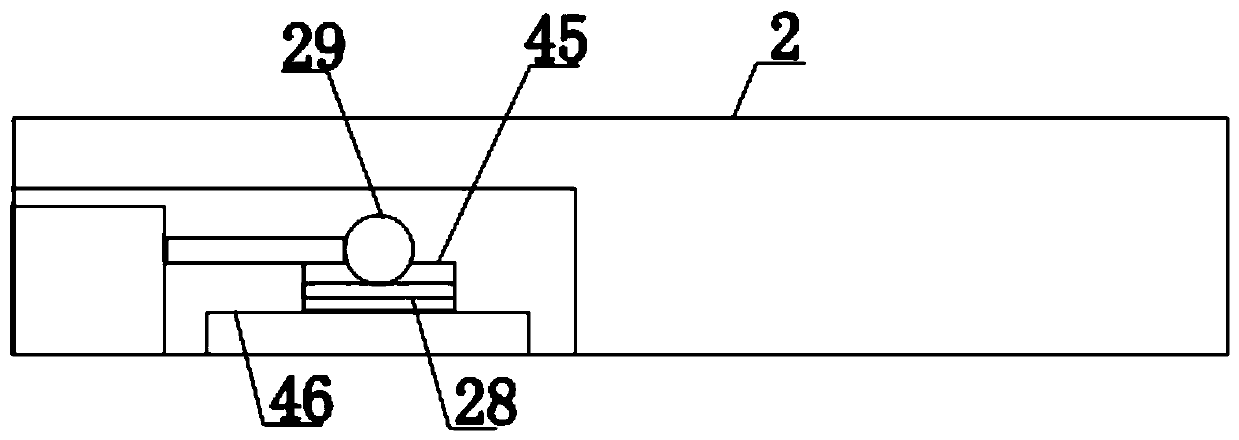

[0031] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, and 14, a fully automatic intelligent sand screening machine for construction sites, including a fixed frame 1, for easy movement , the bottom of the fixed frame can be provided with a universal wheel with a locking device. This is the prior art and will not be repeated here. The sand screening mechanism for sand screening and the sand delivery mechanism for transporting sand to the sand screening mechanism , and a crushing mechanism for crushing the sand particles screened by the sieving mechanism, an adjustment assembly for adjusting the crushing specifications of the crushing mechanism, and a conveying mechanism for transporting the sand particles crushed by the crushing mechanism to the sand sieving mechanism, the sieve The sand mechanism includes a sand screening frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com