Full-automatic intelligent holding pole for communication tower antenna

An iron tower antenna and fully automatic technology, applied in the field of communication signal transmission, can solve the problems of staff inconvenience, manual changes, and increase the workload of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

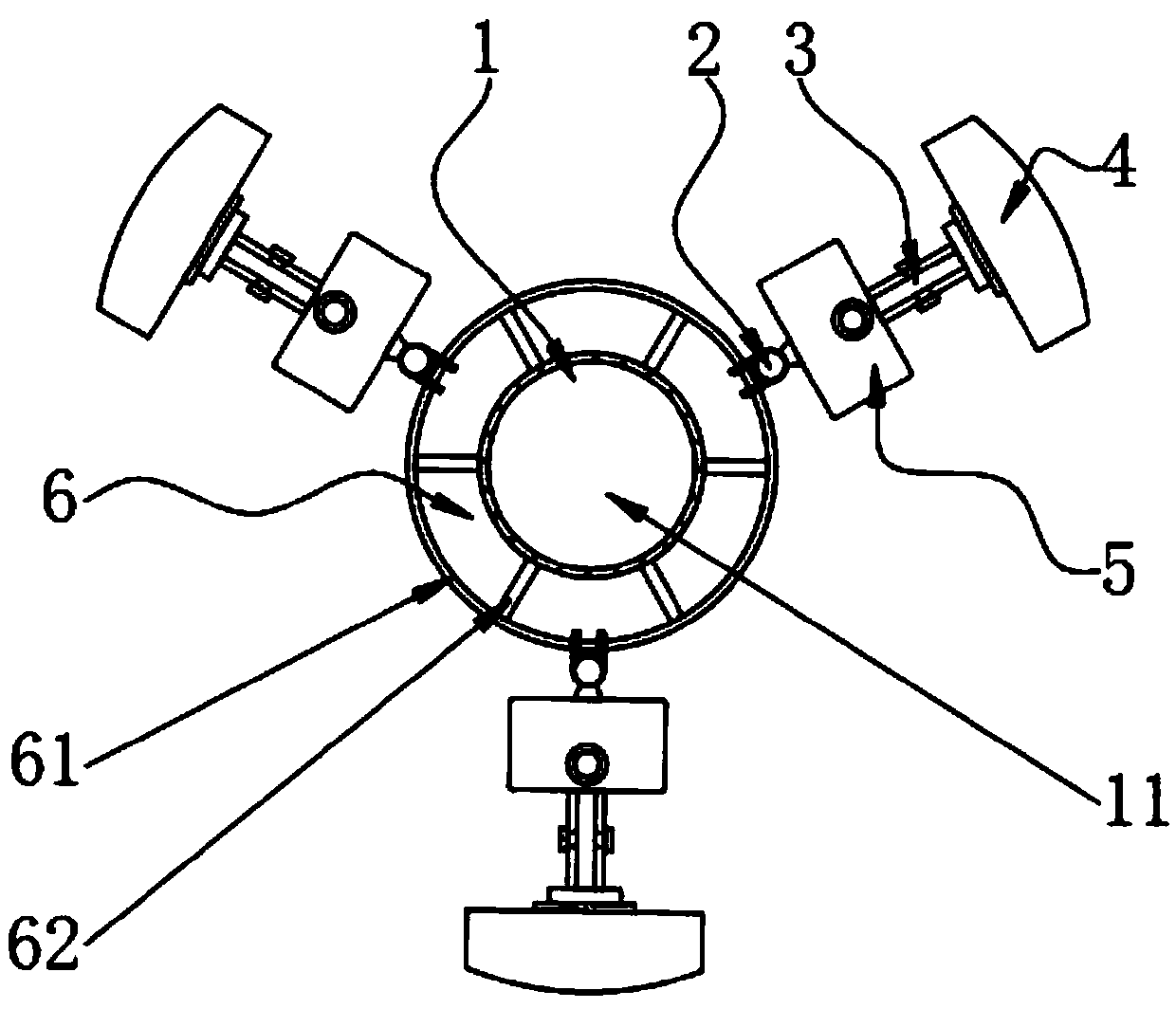

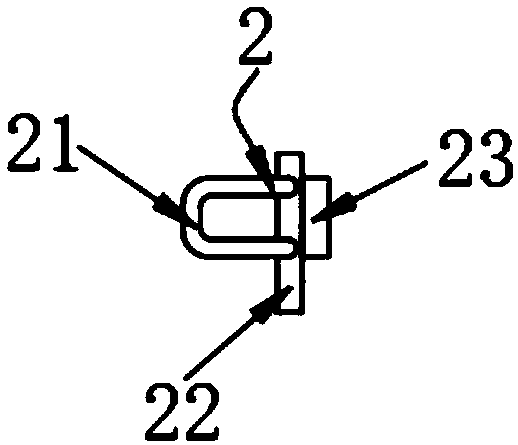

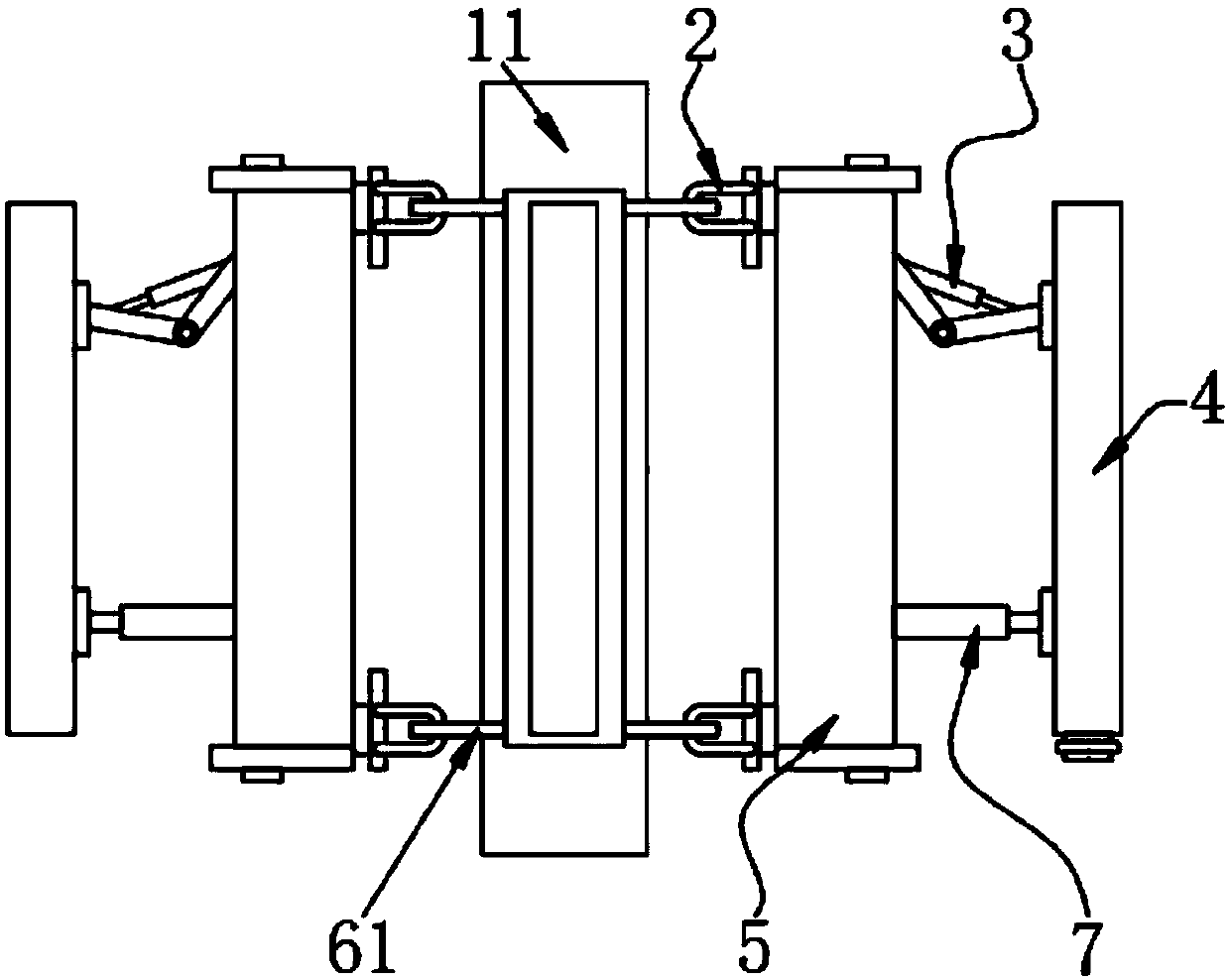

[0036] see Figure 1-Figure 3 , the present invention provides a technical solution: a fully automatic intelligent pole holding pole for a communication tower antenna, including a support assembly 1, a fixing assembly 6 located on one side of the support assembly 1, and a connecting assembly 2 sleeved on the fixing assembly 6, and the support assembly 1 includes a support rod 11, the fixing assembly 6 includes a steel ring 61 and an inner connecting rod 62, the steel ring 61 is sleeved on one end of the supporting rod 11, and the inner side wall of the fixing assembly 6 is welded and fixed with an inner connecting rod 62, the fixing assembly 6 and The support rod 11 is fixed by welding the inner connecting rod 62. The connecting assembly 2 is mainly composed of a connecting ring 21, a first connecting plate 22 and a clamping plate 23. The connecting ring 21 is sleeved on the outer wall of the steel ring 61, and the steel ring 61 is engaged Connection, the side of the connectin...

Embodiment 2

[0044] see Figure 4 , in this embodiment: the vertical movement of the signal transmitting assembly 4 is introduced, and the placement assembly 5 includes a holding rod 51, a first motor 52, a first screw 53, a second screw 54, a third screw 55 and a second screw The motor 56, the holding rod 51 is located on the side of the clamping plate 23 away from the first connecting plate 22, the holding rod 51 and the clamping plate 23 are welded and fixed, and the inside of the holding rod 51 is a hollow structure, the first motor 52 is located inside the holding rod 51, and The outer surface of the first motor 52 is welded and fixed with a first base 521, the first motor 52 and the holding rod 51 are welded and fixed by the first base 521, and the transmission end of the first motor 52 is fixedly connected with a first screw rod 53, One end of the first screw mandrel 53 is connected to the transmission end of the first motor 52, and the other end extends to the top of the first moto...

Embodiment 3

[0050] see Figure 5 , in the present embodiment: the horizontal rotation of the signal transmitting assembly 4 is introduced, (combined with the conditions of embodiment 2) a second motor 56 is provided on one side of the second screw mandrel 54, and the outer wall of the second motor 56 is fixedly provided with a second The base 561, the second motor 56 and the holding rod 51 are welded and fixed by the second base 561, the transmission end of the second motor 56 is provided with a transmission chain 563, and the outer wall of the third screw rod 55 is close to the first sleeve shaft 553 The top of the transmission gear 562 is also sleeved, and one end of the transmission chain 563 is sleeved on the transmission gear 562, and the transmission gear 562 is slidingly connected, and the other end of the transmission chain 563 is sleeved on the transmission end of the second motor 56.

[0051] In this embodiment: when the second motor 56 rotates, the transmission chain 563 drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com