Instrument and method for measuring volume change of battery cell

A technology of volume change and electric core, which is applied in the direction of instruments, measuring devices, and fluid devices, etc., can solve the problems of large battery consumption, high production cost, and high cost, and achieve accurate test results, simple operation, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

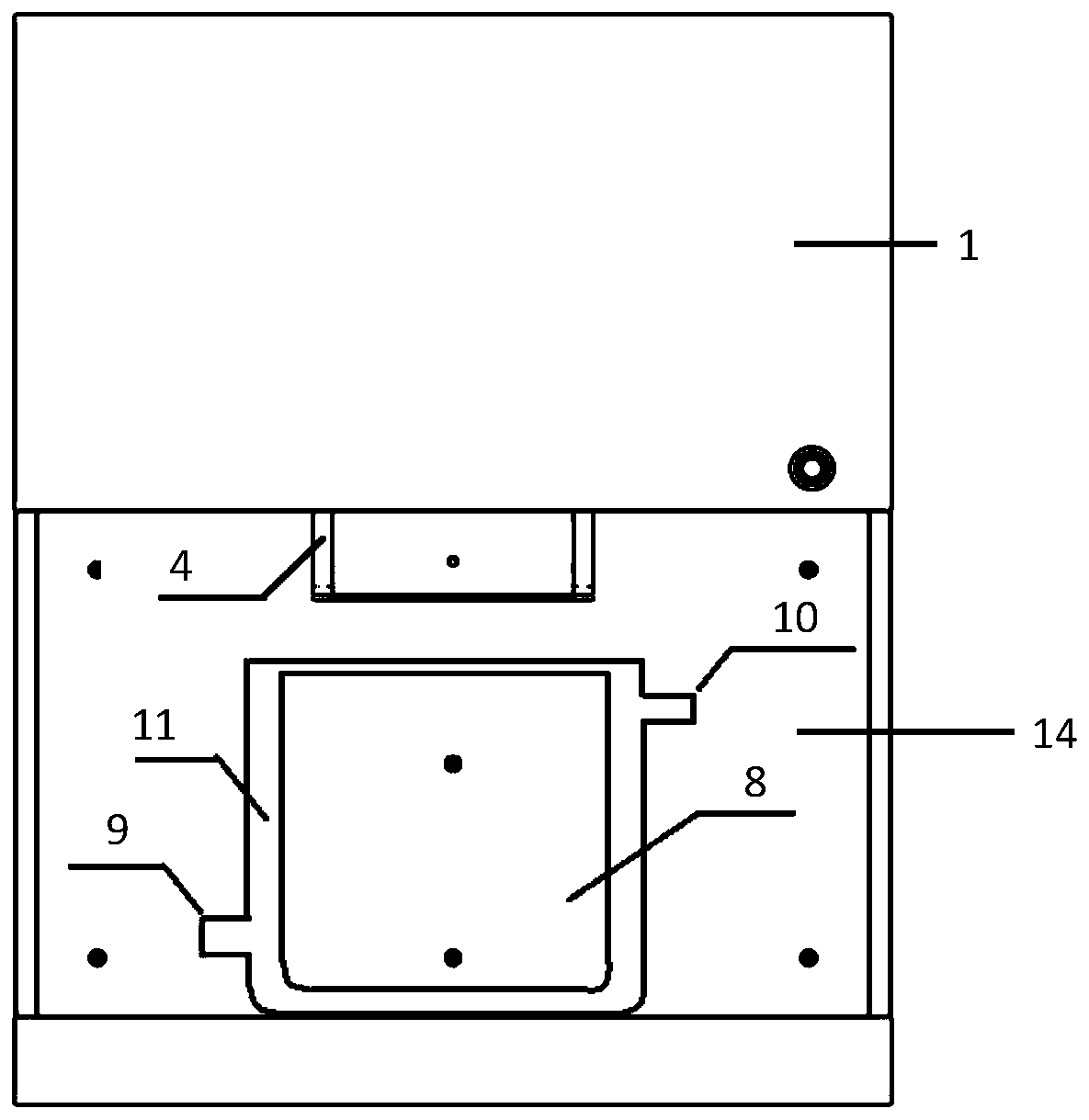

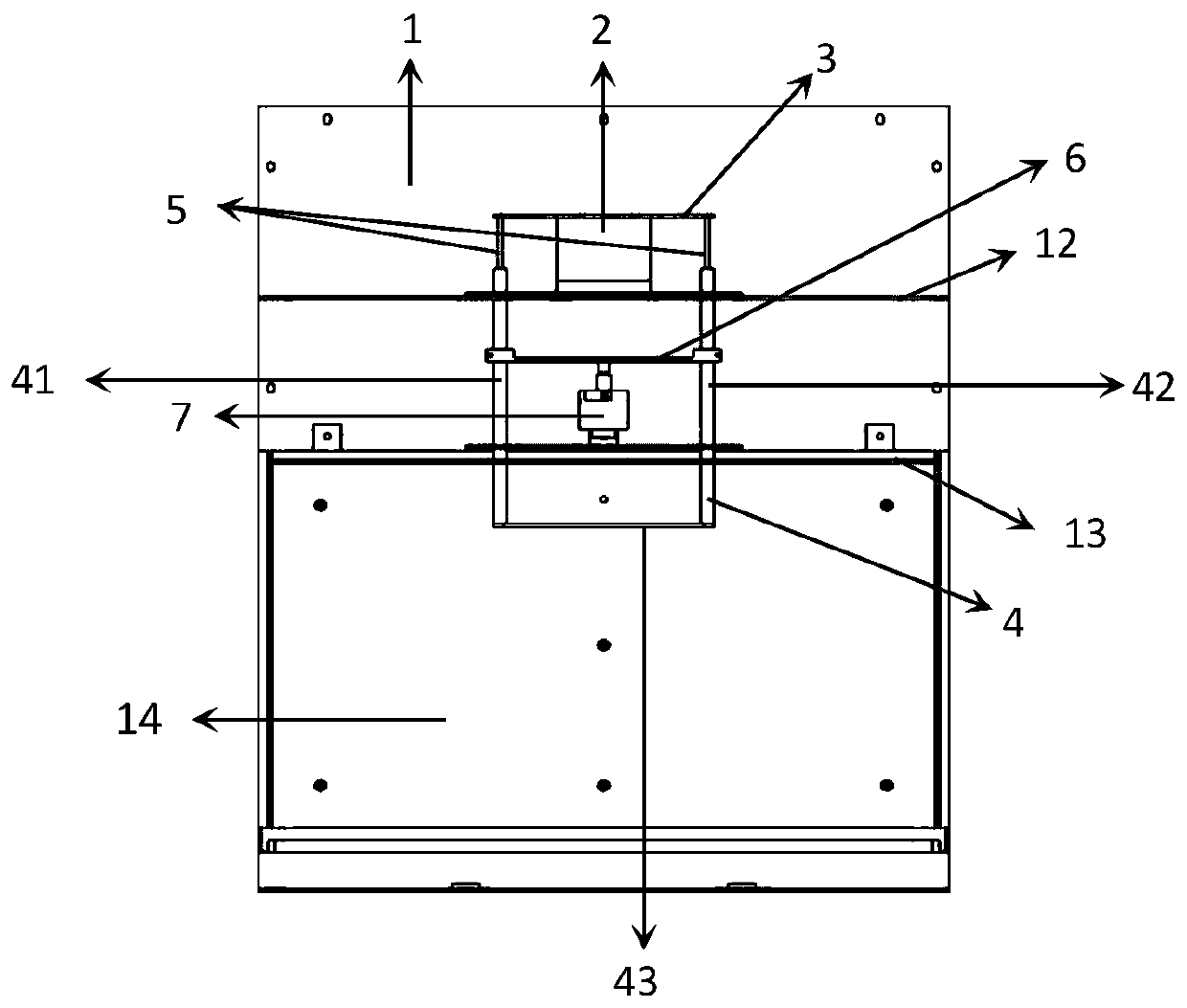

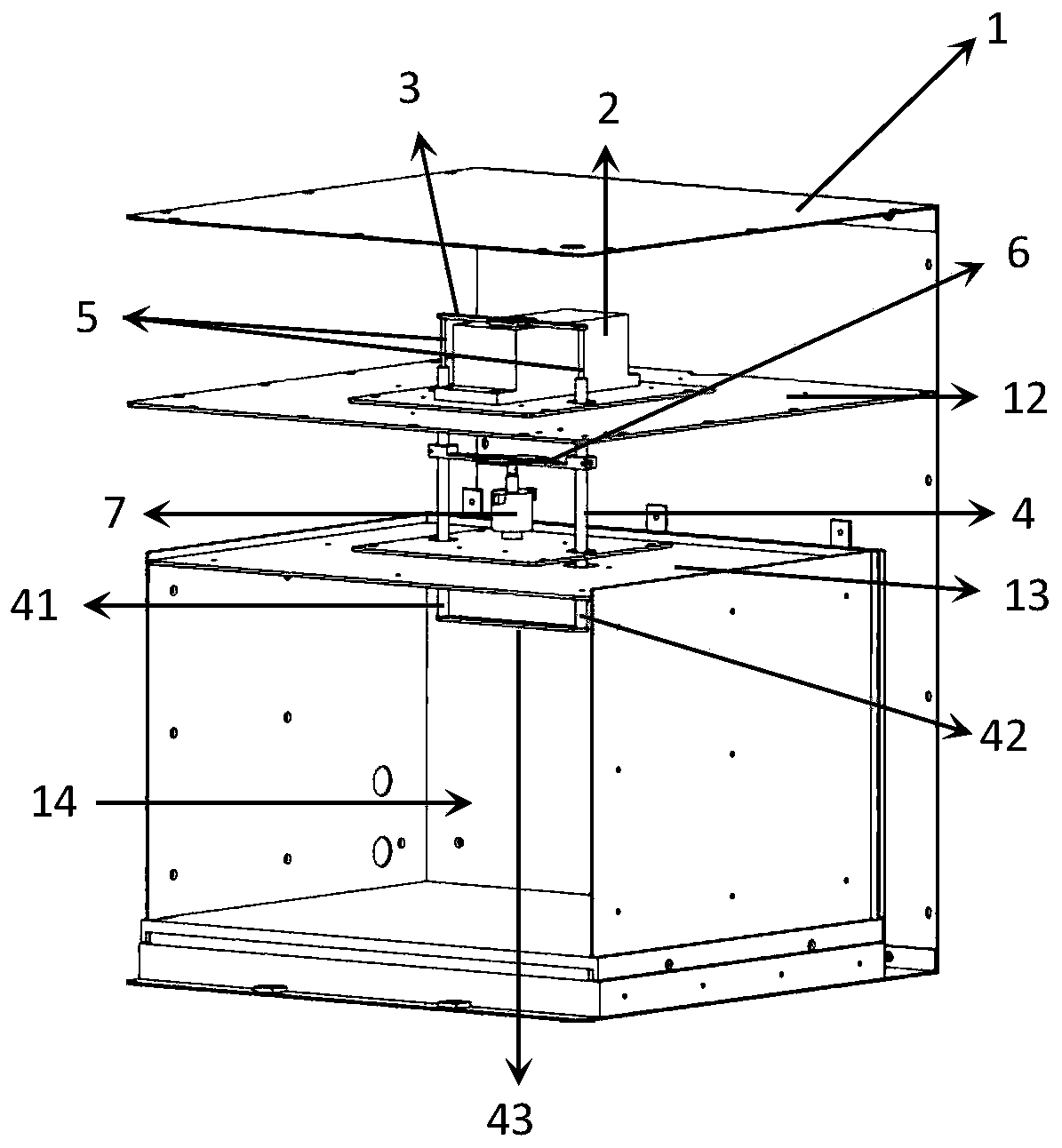

[0040] Such as Figure 1~2 As shown, this embodiment provides an instrument for measuring the volume change of the cell, which includes a housing 1, a high-precision mechanical sensing system and a measuring terminal.

[0041] Wherein, the housing 1 can be made of metal material, which forms a relatively closed accommodation space to accommodate the high-precision mechanical sensing system and the measuring end, thereby ensuring that the high-precision mechanical sensing system and the measuring end are in a relatively close position. Stable working environment.

[0042] In this embodiment, the high-precision mechanical sensing system includes a high-precision weight sensor 2 and a sensor bracket 3, and the high-precision weight sensor 2 is fixedly installed in the housing 1; the sensor bracket 3 is installed on the On the high-precision weight sensor 2, its two ends exceed the high-precision weight sensor 2.

[0043] Specifically, in this embodiment, the high-precision weig...

Embodiment 2

[0055] Such as figure 1 As shown, preferably, on the basis of the above embodiments, in this embodiment, the container is a double-layer beaker 8, the outer wall of the double-layer beaker 8 is provided with a water inlet 9 and a water outlet 10, and the double-layer beaker 8 is provided with a water inlet 9 and a water outlet 10, and the double-layer beaker The interlayer 11 of the beaker 8 can pass water to heat the bath liquid and the electric core in a water bath.

[0056] Heated by a water bath, it can meet the temperature conditions of the cell expansion test, which is safe and easy to control the temperature.

Embodiment 3

[0058] Such as image 3 As shown, preferably, on the basis of the above-mentioned embodiments, in this embodiment, an upper inner plate 12 and a lower inner plate 13 are also arranged in the housing 1; the high-precision weight sensor 2 is arranged on the On the upper inner plate 12, the lower inner plate 13 and the bottom plate of the housing 1 constitute the accommodating cavity 14; the first connecting arm 41 and the second connecting arm 42 of the measuring bracket 4 are not in contact with each other. Passes through the upper inner panel 12 and the lower inner panel 13 and extends into the accommodating cavity 14 ; the third connecting arm 43 is located in the accommodating cavity 14 . Non-contact traversal can eliminate the interference of friction force on test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com