Formula of dark blue reactive dye for all-cotton and all-cotton blended fabric and application thereof

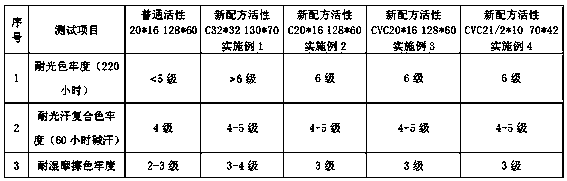

A technology for reactive dyes and blended fabrics, applied in the field of navy blue reactive dye formulations, can solve the problems of poor light fastness and color fastness of reactive dyes, and achieve the effects of high dry and wet rubbing fastness, low wastewater treatment pressure, and efficient and stable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

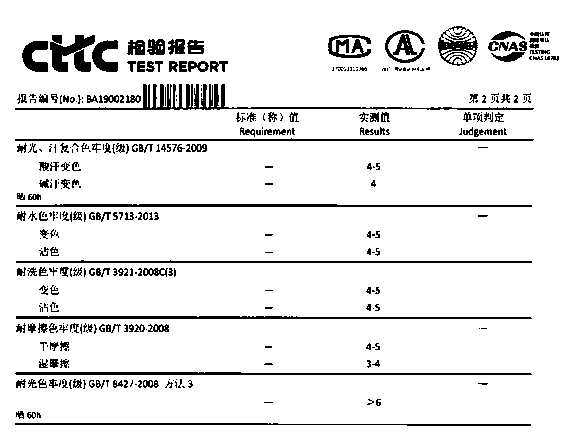

[0027] Cotton fabric 63"32*32 130*70 Twill workwear fabric High lightfast navy blue reactive dye formula, including the following components by weight: Encai Clone Navy Blue PL-N 43g / L, Encai Clone Crimson SF 7.2 g / L and Yingcai Clone Orange CD3.96g / L.The navy blue reactive dye is used to dye the cotton fiber in the fabric, and the dyeing process includes fabric pretreatment, fabric dyeing and fabric finishing and finalizing successively. Dyeing sequentially includes the steps of pad dyeing, pre-drying, steaming, soaping, color fixing and drying.

[0028] In this embodiment, the pretreatment of the fabric includes desizing, scouring, oxygen bleaching, singeing and mercerizing in sequence, all carried out according to the existing process. In the pad dyeing and coloring step, the blended fabric is The relative moving speed of the dye bath solution in the medium is 50 yards / minute, the temperature in the pre-drying step is 78°C, the temperature in the drying step is 90°C, and th...

Embodiment 2

[0035] Cotton fabric 63” 20*16 128*60 3 / 1 Workwear fabric High light fast navy blue reactive dye formula, including the following components by weight: Yingcai clone navy blue PL-N 30g / L, Yingcai clone dark red SF 6.0g / L and Ying Cai clone orange CD3.1g / L.Described navy blue reactive dyestuff is used for dyeing the cotton fiber in the fabric, and dyeing process comprises fabric pretreatment, fabric dyeing and fabric post-finishing setting in sequence, so Said fabric dyeing sequentially includes the steps of pad dyeing, pre-drying, steaming, soaping, color fixing and drying.

[0036] In this embodiment, the pretreatment of the fabric includes desizing, scouring, oxygen bleaching, singeing and mercerizing in sequence, all carried out according to the existing process. In the pad dyeing and coloring step, the blended fabric is The relative moving speed of the dyeing bath in the middle is 50 yards / minute, the temperature in the pre-drying step is 75°C, the temperature in the dryin...

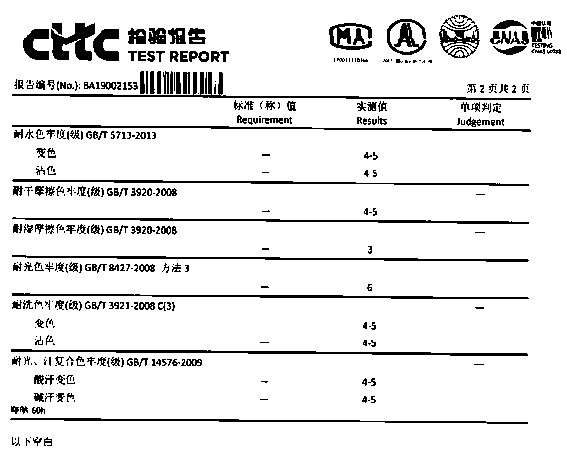

Embodiment 3

[0043] 60% cotton, 40% polyester fabric 63”20*16 128*60 3 / 1 Tooling fabric High lightfast navy blue reactive dye formula, the coloring steps are to dye the polyester fiber with disperse dyes first, and then use Reactive dyestuff is to cotton fiber dyeing, accomplishes two colors to be consistent.Described disperse dyestuff comprises the following components by weight: Yingcaixiu navy blue HSF-N14g / L, Yingcaixiu yellow brown HSF01 2.4g / L, Yingcaixiu yellow brown HSF01 2.4g / L, Caixiu black HSF01 2.4g / L. The dyeing process includes fabric pretreatment, fabric dyeing, and fabric finishing and finalizing successively. dry step.

[0044] The above reactive dyes include the following components by weight: Yingcai clone navy blue PL-N 24.5g / L, Yingcai clone deep red SF 7.7g / L. The dyeing process includes pad dyeing, pre-drying, steaming, soaping, color fixing and drying steps in order to achieve the same two colors.

[0045] In this embodiment, the pretreatment of the fabric include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com