Separable brewing material dumping device capable of discharging at bottom

A technology of unloading device and bottom unloading, which is applied in the direction of packaging, transportation and packaging, containers, etc., can solve the problems of high labor intensity, harsh on-site environment, and low production efficiency, and achieve low cost, high degree of automation, unloading, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

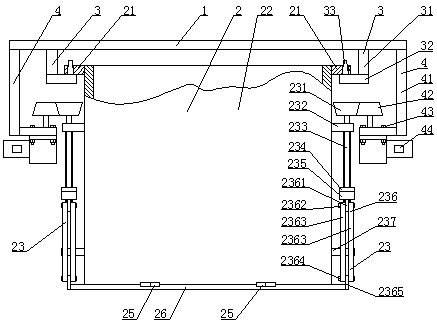

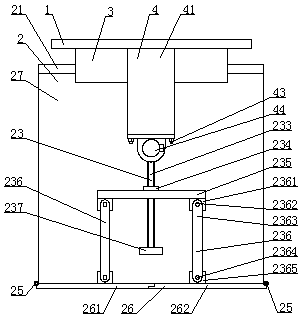

[0008] see Figure 1 to Figure 2 , the present invention comprises a spreader frame 1, a material box 2, two left and right symmetrically arranged hook legs 3 and two left and right symmetrically arranged drive assemblies 4, and the described material box 2 includes a box body 22, a side-by-side door 26, two Loading plate 21, two switch door assemblies 23 and several hinges 25, described switch door assembly 23 comprises driven friction wheel 231, upper support 232, screw mandrel 233, nut 234, lift seat 235, lower support 237 and two A link assembly 236, each link assembly 236 includes an upper ear plate 2361, an upper pin shaft 2362, a lower pin shaft 2364, a lower ear plate 2365 and two connecting rods 2363, and the side-by-side door 26 includes a front door panel 261 And rear door panel 262, each described hook leg 3 comprises straight plate 31, horizontal plate 32 and several guide cone columns 33, and each described driving assembly 4 comprises support 41, driving frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com