Automatic feeding device and intelligent cutting equipment

An automatic feeding and feeding technology, applied in thin material handling, sending objects, transportation and packaging, etc., can solve the problems of inaccurate leather material conveying, cylinder easily stuck, unstable positioning, etc., to avoid later docking problems, The effect of improving the feeding accuracy and preventing the cylinder from being out of synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

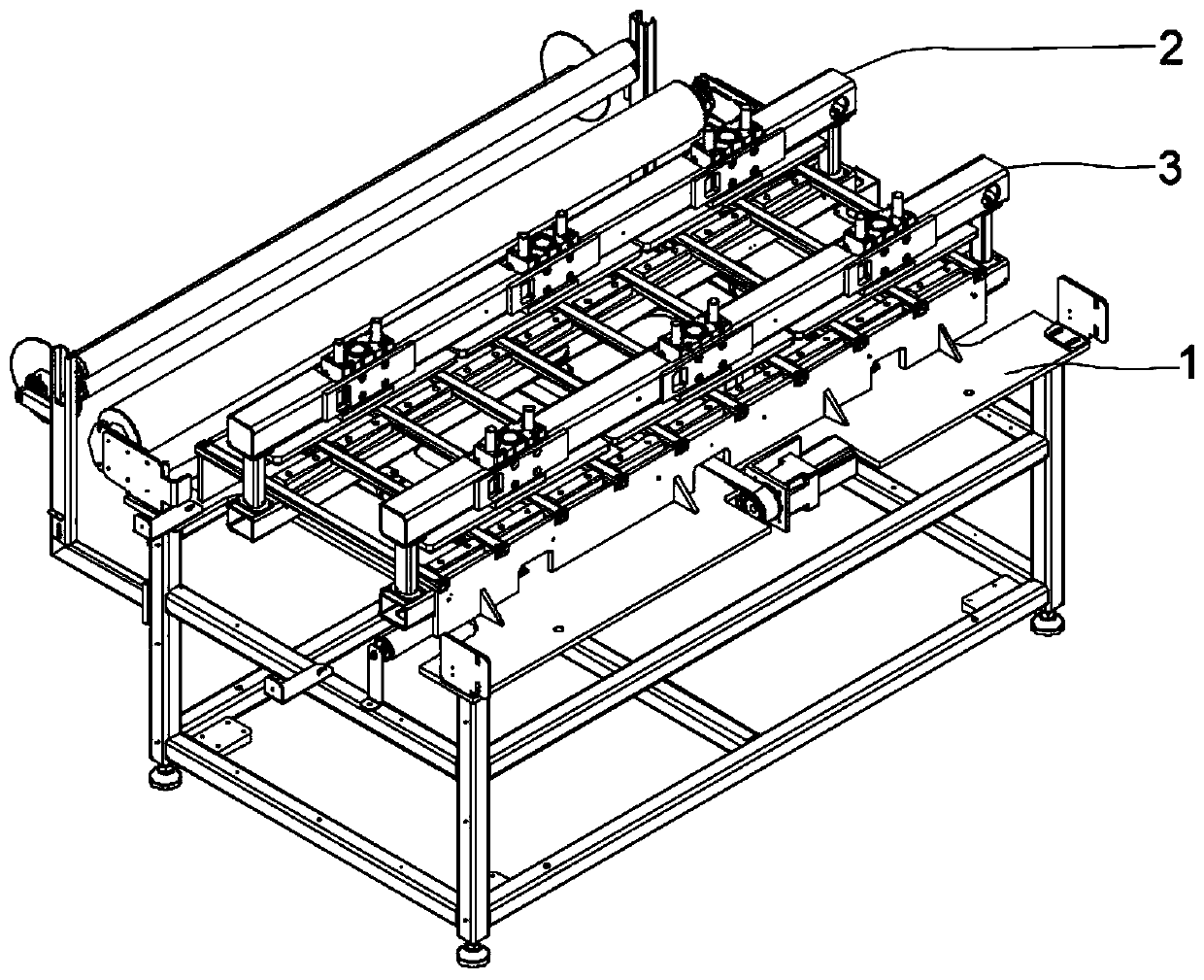

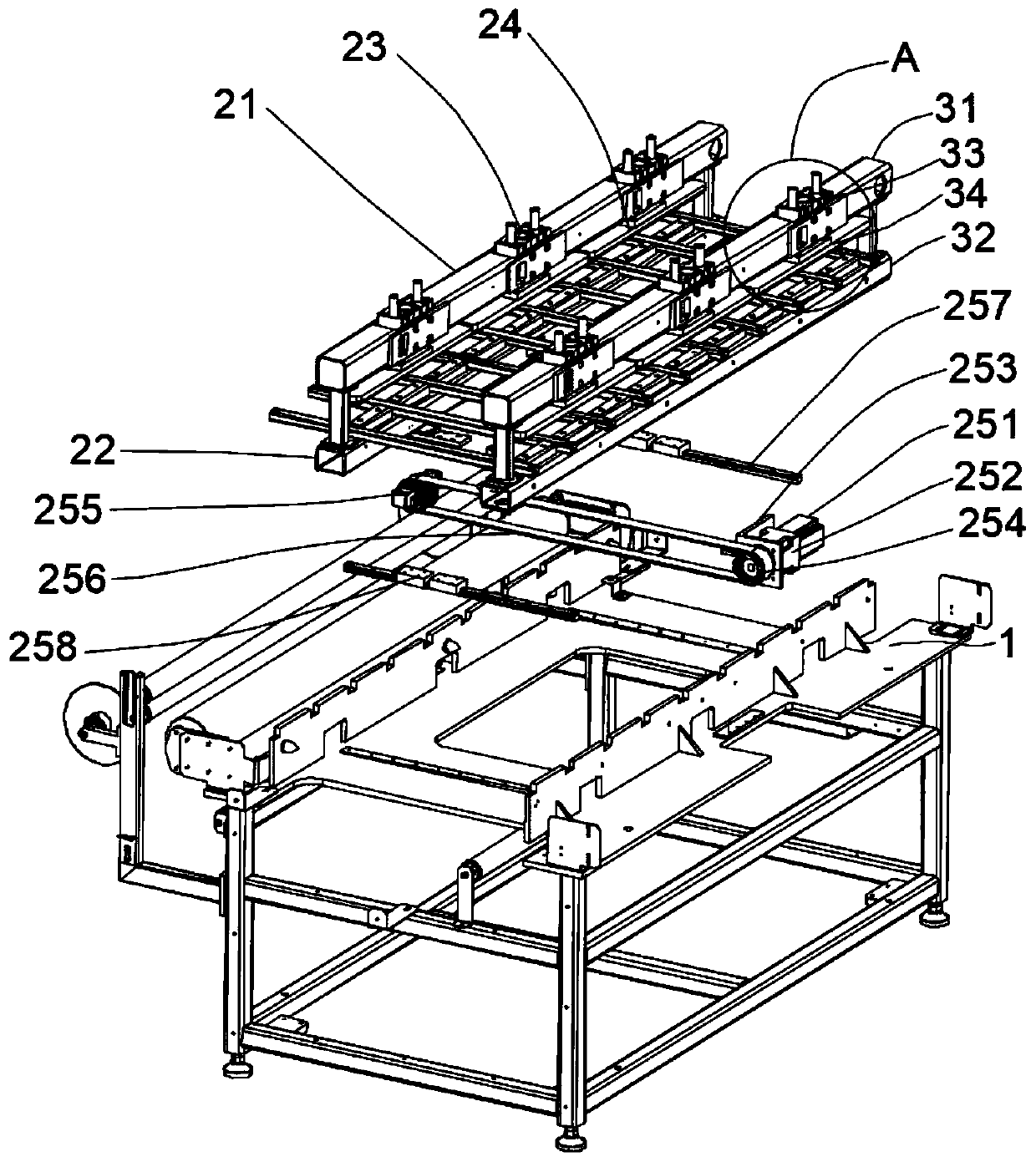

[0029] see Figure 1-4 As shown, the present invention relates to an automatic feeding device, including an installation platform 1, on which a movable pulling mechanism 2 and a fixed pressing mechanism 3 are arranged, and the movable pulling mechanism 2 moves on the installation platform 1 For feeding, the fixed pressing mechanism 3 is arranged behind the movable pulling mechanism 2 for positioning the pressing.

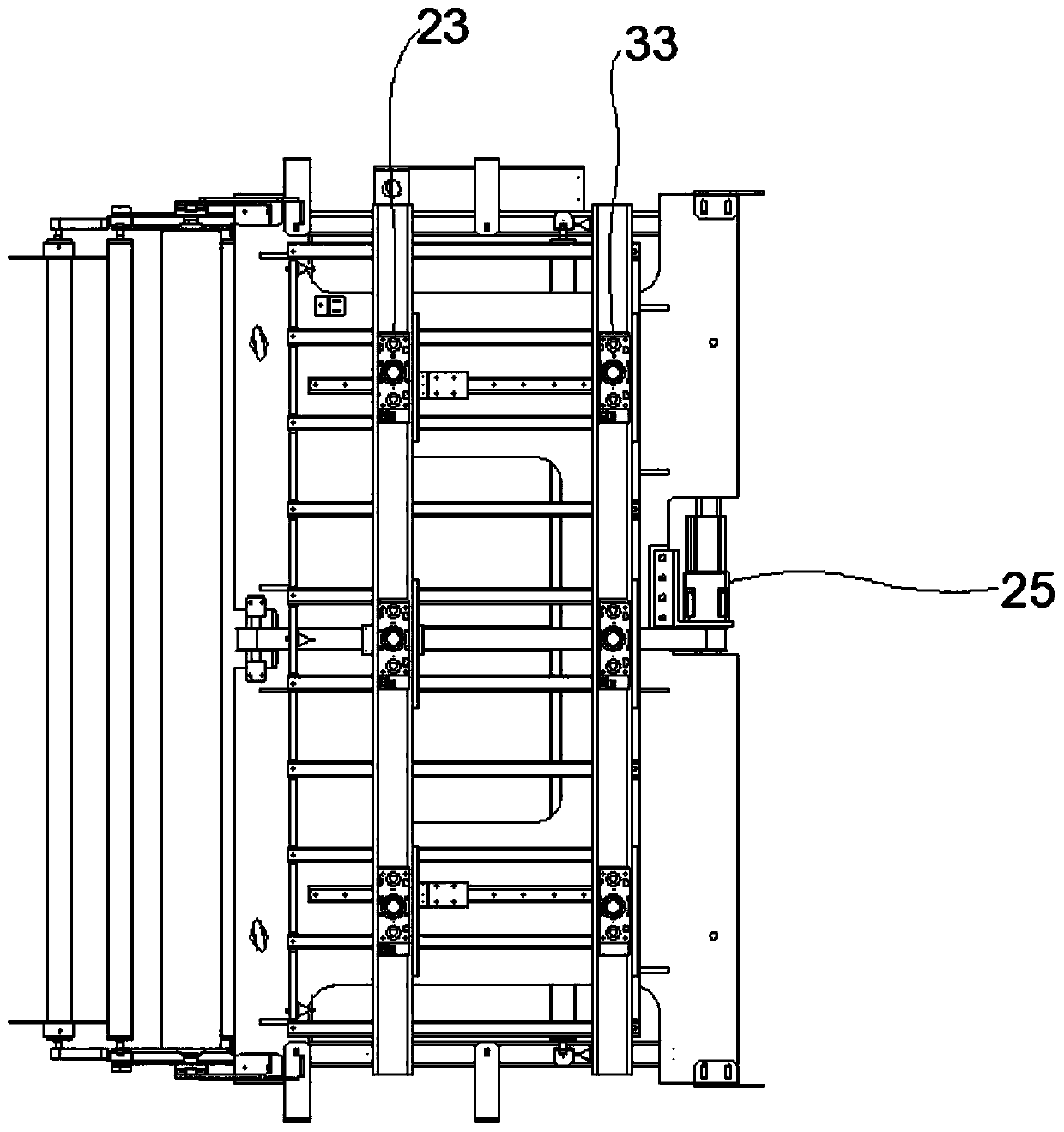

[0030] Preferably, the movable pulling mechanism 2 includes a first upper beam 21, a first lower beam 22, a first driving device 23, a first pressing plate 24 and a feeding driving mechanism 25, and the feeding driving mechanism 25 is arranged on the installation table 1 Above, the first lower beam 22 is set on the feeding drive mechanism 25, the first upper beam 21 is fixed on the first lower beam 22 through a connecting rod, and the first upper beam 21 is provided with three first driving Set 23, the first platen 24 is respectively connected under the three first...

Embodiment 2

[0034]This embodiment is a modification of Embodiment 1. The change is that: the feeding drive mechanism 25 is a screw transmission mechanism, including a servo motor 251, a reduction motor 252, a motor seat 253, a transmission screw, a screw nut, a connection Seat, straight line rail 257 and guide block 258, the transmission screw rod is arranged in the installation platform 1, the screw nut is set on the transmission screw rod, and the reduction motor 252 is arranged on the installation platform through the motor base 253 1 and is connected with the transmission screw, the servo motor 251 is connected with the reduction motor 252, the connecting seat is connected with the screw nut, two straight line rails 257 are respectively arranged on the installation platform 1, and two straight Guide blocks 258 are arranged on the line rails 257 respectively, and the first lower beam 22 is arranged on the guide blocks 258 and the connecting seat.

Embodiment 3

[0036] This embodiment is a variation example of Embodiment 1. The variation lies in that: the feeding drive mechanism 25 is a rack and pinion meshing transmission mechanism, including a servo motor 251, a reduction motor 252, a motor base 253, a transmission gear, a rack, a straight Profile rail 257 and guide block 258, the rack is slidably arranged on the mounting table 1, the transmission gear is meshed with the rack, and the reduction motor 252 is arranged on the mounting table 1 through the motor base 253 and is driven with the transmission gear. connected, the servo motor 251 is connected with the geared motor 252, the straight line rail 257 is set on the installation table 1, the guide block 258 is slid on the straight line track 257, and the first lower beam 22 is set On the guide block 258 and the rack.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com