Glue scraping and discharging device and method for unscrewing cover

A technology of squeegee and squeegee, which is applied to the device and coating of the surface coating liquid, which can solve the problems of wrinkling, over-thickness, and lack of glue on the cover, and achieve high practical value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

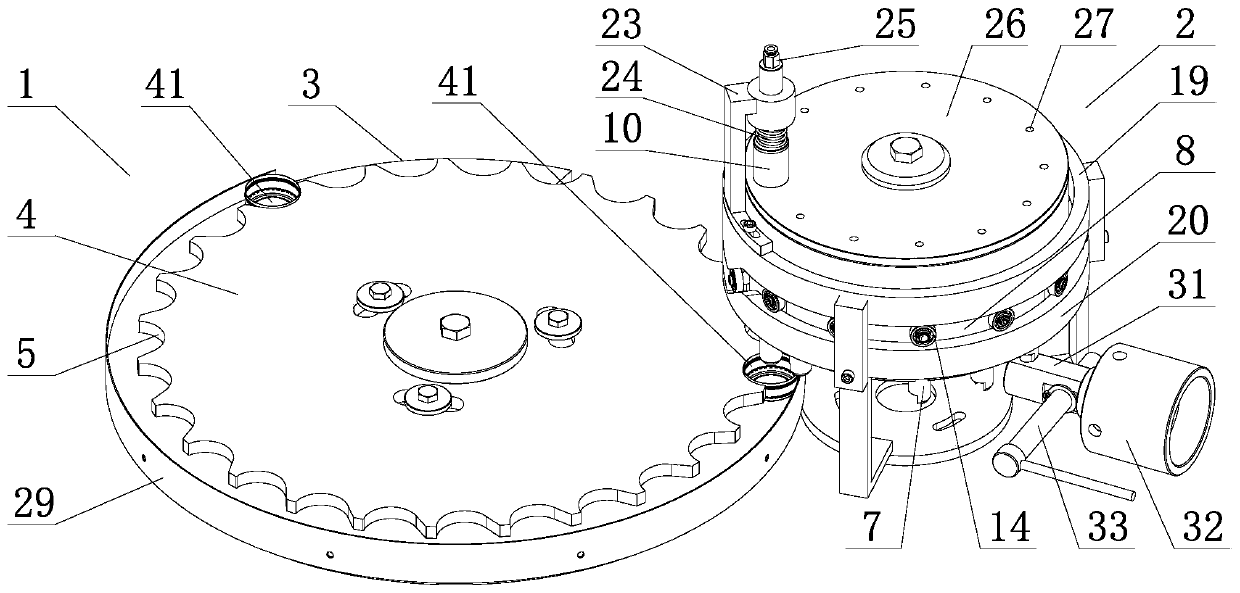

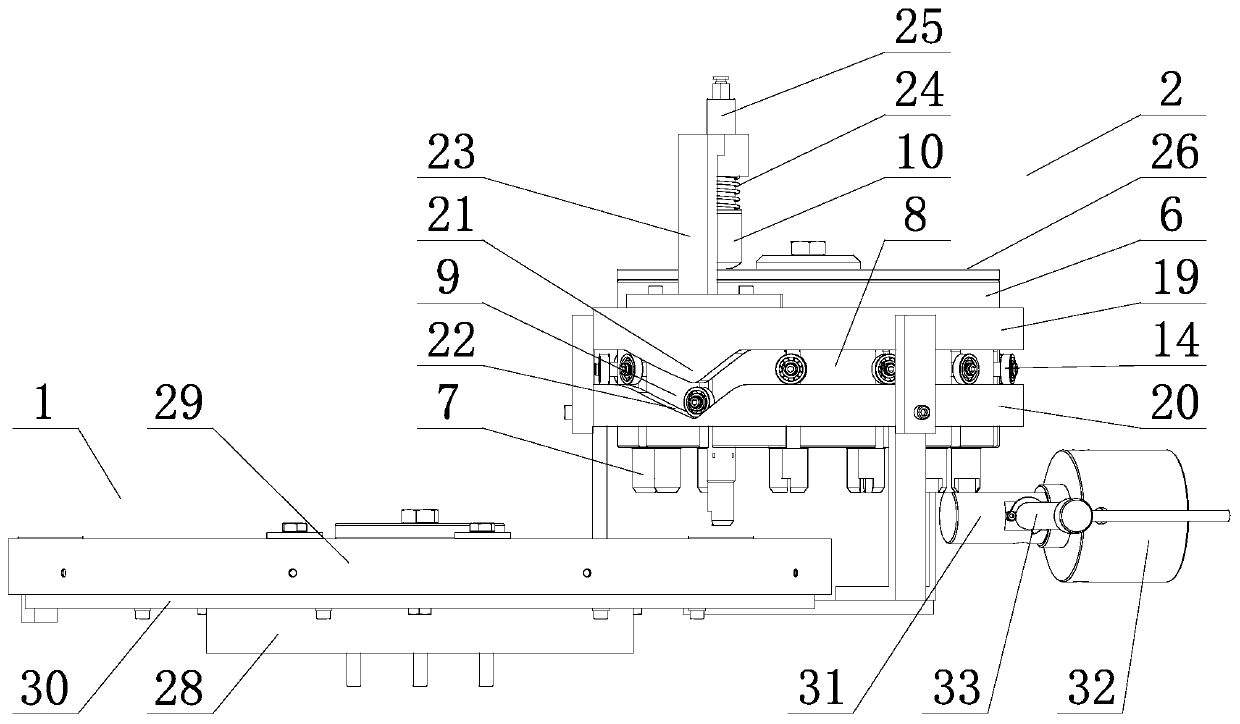

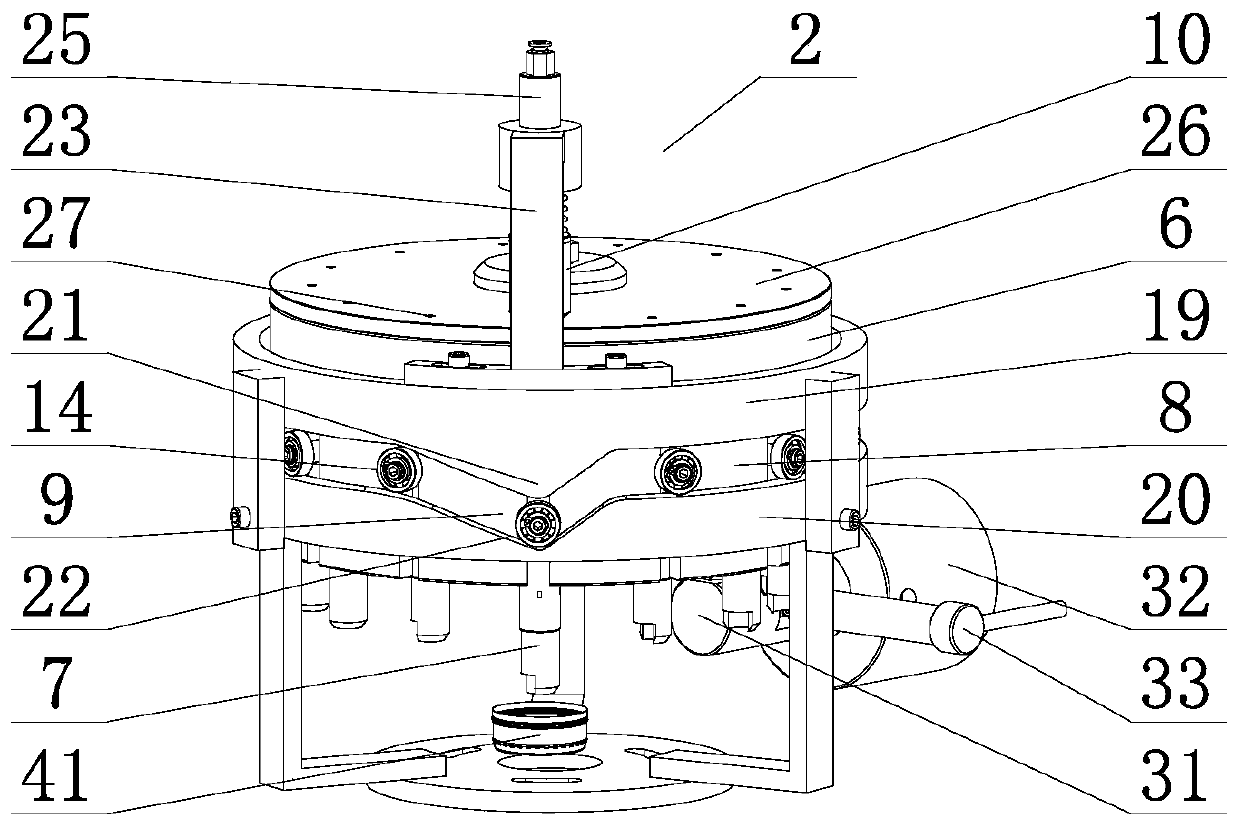

[0030] exist figure 1 figure 2 In the shown embodiment 1, a scraping and unloading device for unscrewing the cap is used for the glue adding process of unscrewing the cap, including a cap feeding device 1 and a glue feeding device 2 arranged side by side, and the cap feeding device Including the supporting cover plate 3 and the cover feeding star wheel 4 arranged on the supporting cover plate, the outer circumference of the cover feeding star wheel is provided with 27 cover gaps 5 (that is, 27 stations); the glue feeding device includes rubber particles The extruding mechanism and the rubber lowering runner 6, the cover feeding star wheel, the rubber lowering runner and the rubber particle extrusion mechanism are mechanical linkage structures. The rubber particle extrusion mechanism includes an extrusion head 31, the extrusion head is fixed on the extrusion head base 32, an extrusion switching swing bar 33 is provided at the rear of the extrusion head, and an opening is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com