Production line for washing abdominal pad

An abdominal pad and production line technology, applied in abdominal bandages, medical science, dressings, etc., can solve problems such as increasing secondary pollution, reduce production costs, reduce manual contact with products, and increase production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

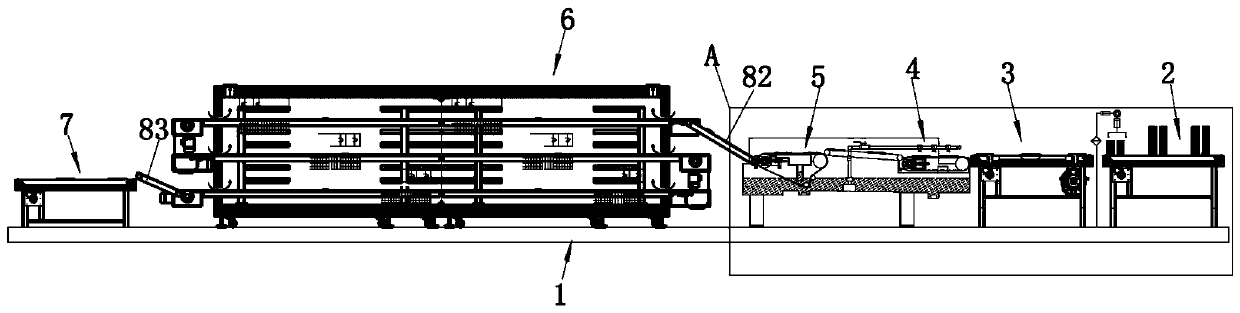

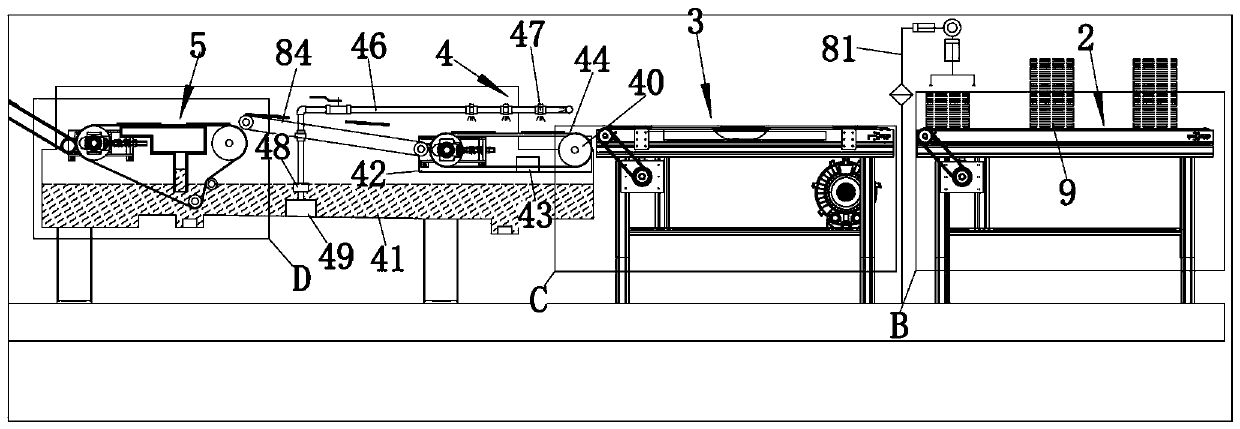

[0033] Examples such as Figure 1 to Figure 9 As shown, a water-washed abdomen pad production line includes a mounting substrate 1, on which a feeding mechanism 2, a suction conveying mechanism 3, an oscillating spray mechanism 4, a water absorption mechanism 5, and a drying Dry box 6 and discharge mechanism 7;

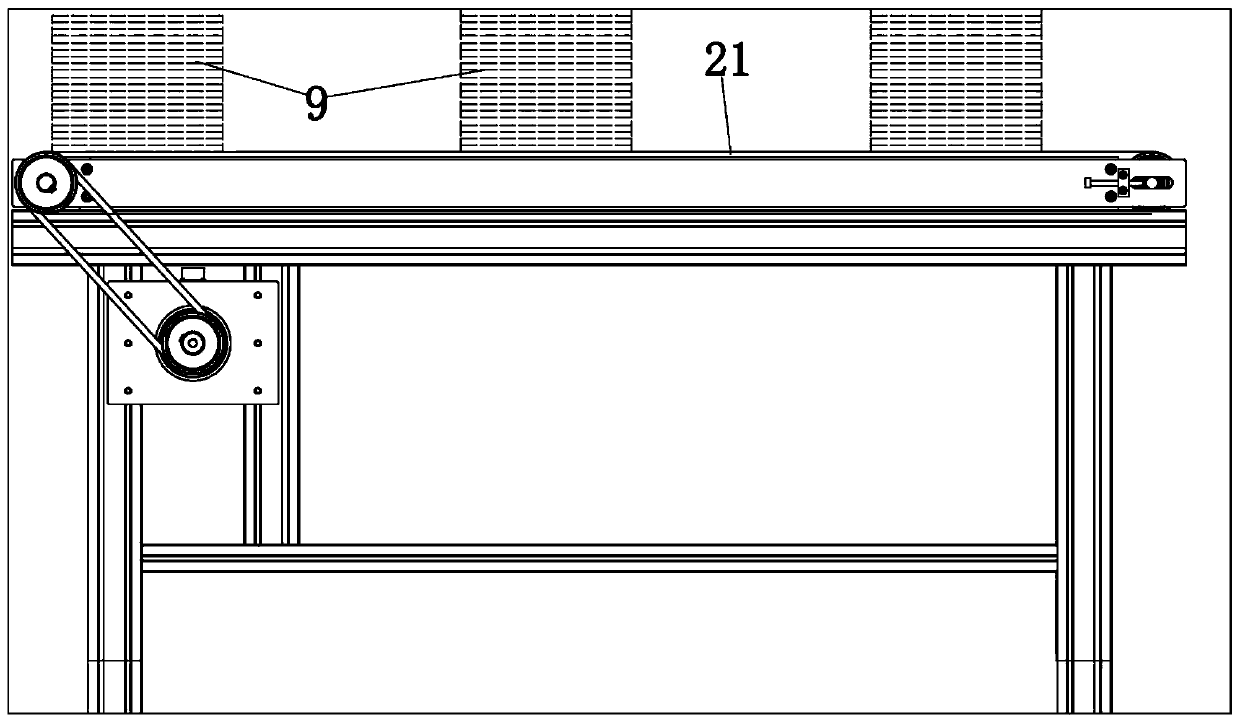

[0034] The feeding mechanism 2 includes an intermittently driven feeding conveyor belt 21, and the feeding conveyor belt 21 is provided with multiple stacks of linear and uniformly distributed abdominal pads 9;

[0035] The suction conveying mechanism 3 includes a suction conveyor belt 31. The suction conveyor belt 31 is provided with a number of air holes 311, and the air holes 311 are connected with a first negative pressure box 32; between the suction conveyor belt 31 and the feed conveyor belt 21 is provided Soft touch manipulator 81;

[0036] The oscillating spray mechanism 4 includes a stainless steel water tank 41 fixed on the mounting base plate 1, an oscillating b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com