Die structure capable of automatically positioning and embedding umbrella ribs

A technology of automatic positioning and positioning module, applied in the direction of canes, etc., can solve the problems of slow rivet riveting, mistakes, finger injuries and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

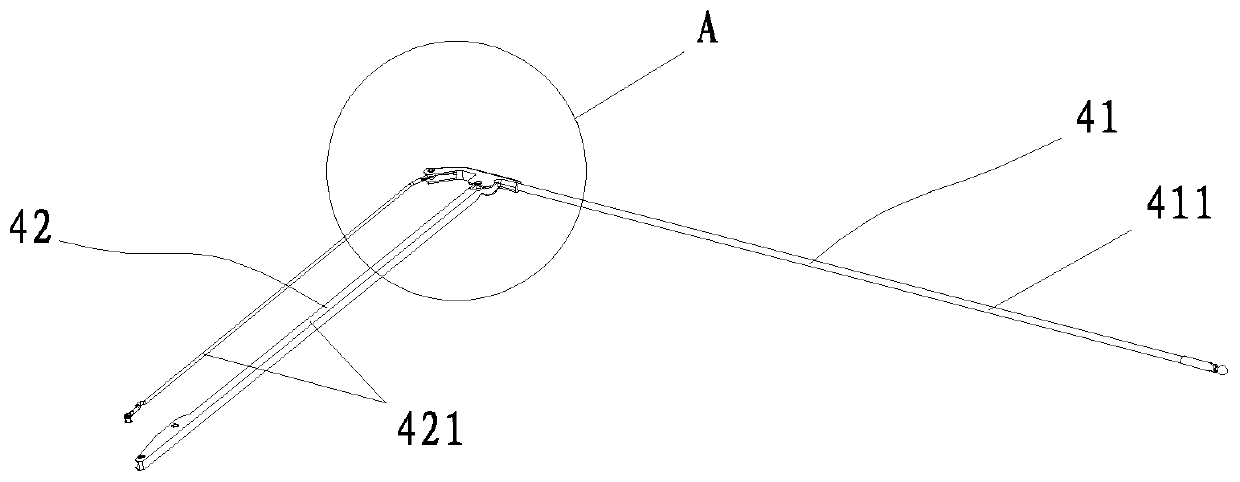

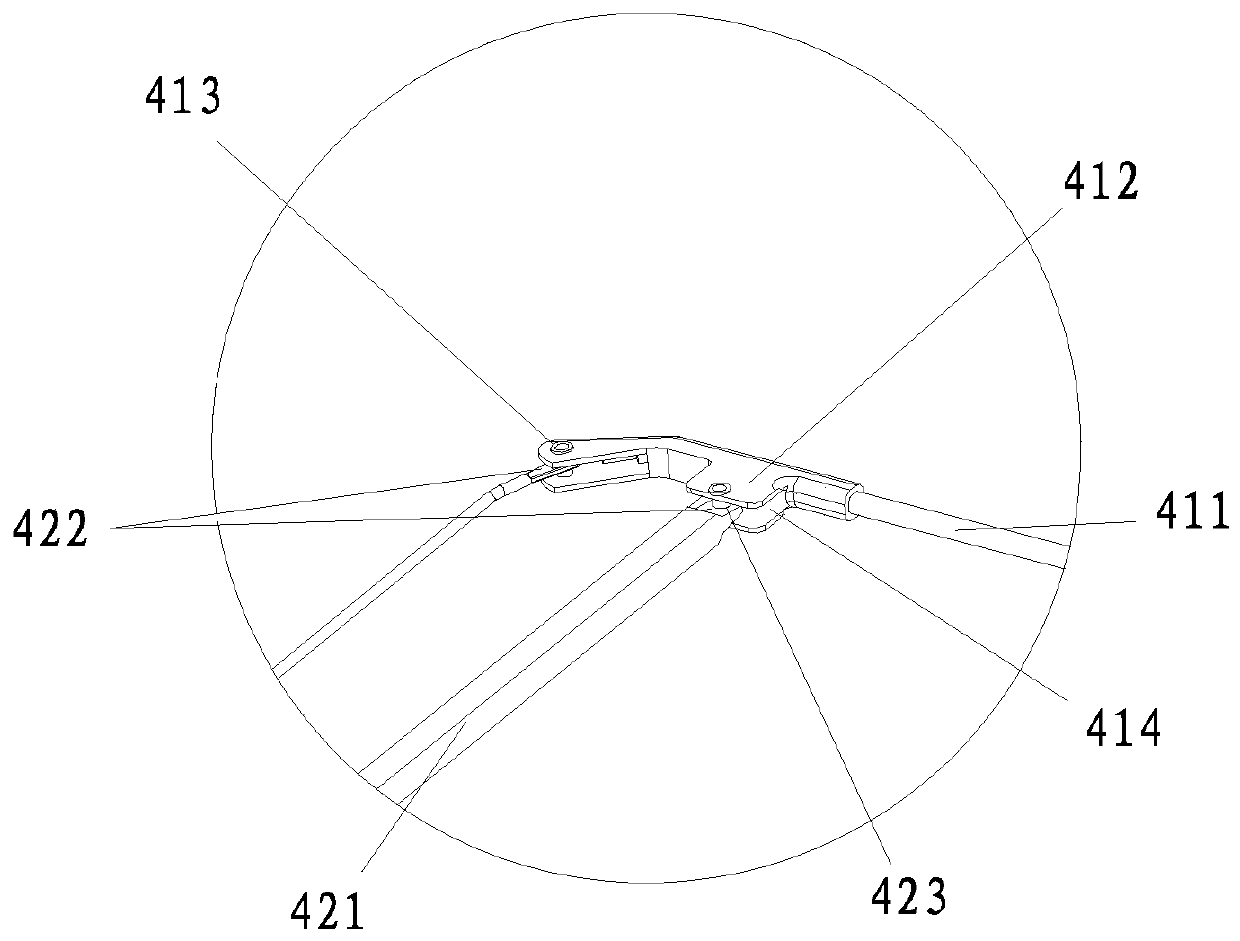

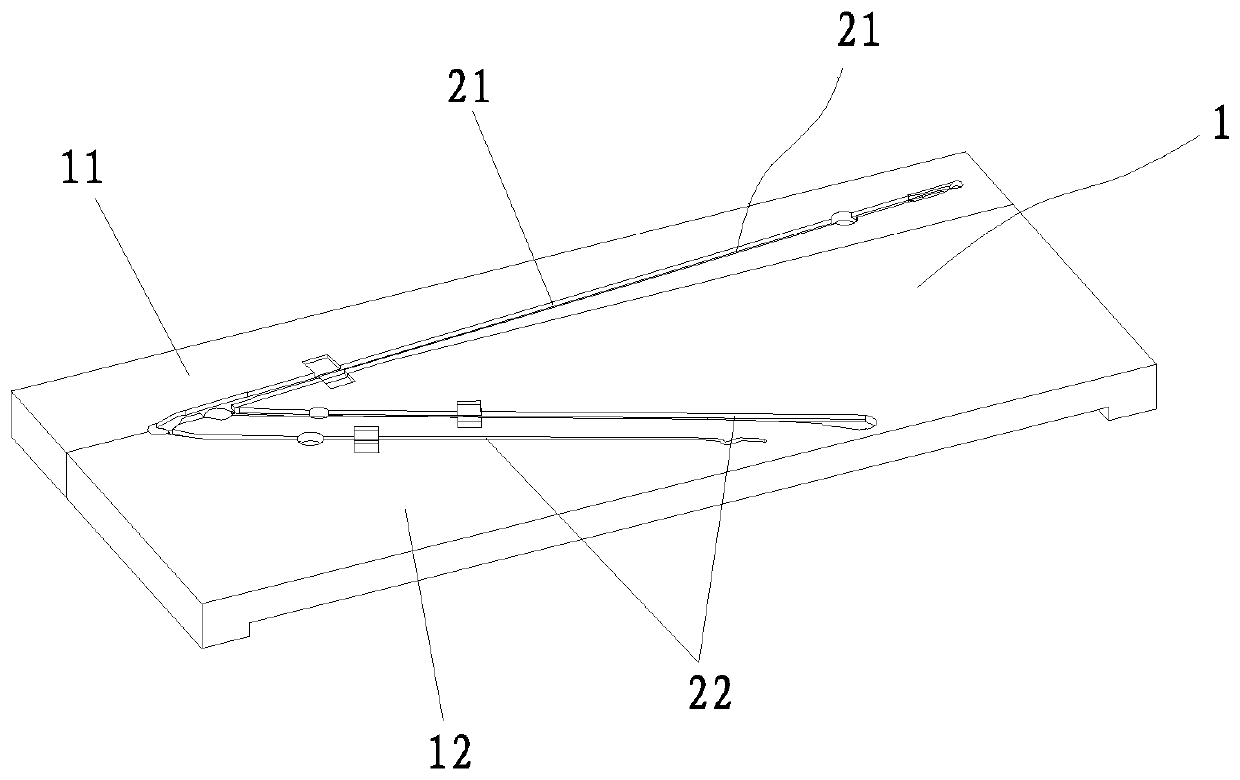

[0031] like Figure 3-7 As shown, a mold structure for automatically positioning and fitting umbrella ribs, which includes several positioning modules 1, and the positioning modules 1 are provided with positioning grooves 2 for fixing umbrella rib segments.

[0032] After the above structure is adopted, the ribs are placed in the corresponding positioning groove 2 for positioning, and then the positioning modules 1 are relatively merged, so that the rib segments in the positioning groove 2 are automatically plugged together, and then sent to the riveting machine for riveting. The lower mold of the riveting machine is in contact with the rib segments through the riveting holes 3, and the rib segments are riveted together.

[0033] Compared with the prior art, the beneficial effect is that the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com