Manufacture method of smell-free dried venison

A production method and technology of venison jerky, which are applied to the functions of food ingredients, food ingredients as taste improvers, climate change adaptation, etc., can solve the problems of not meeting the eating conditions, and achieve the improvement of food taste, good taste, and flavor unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

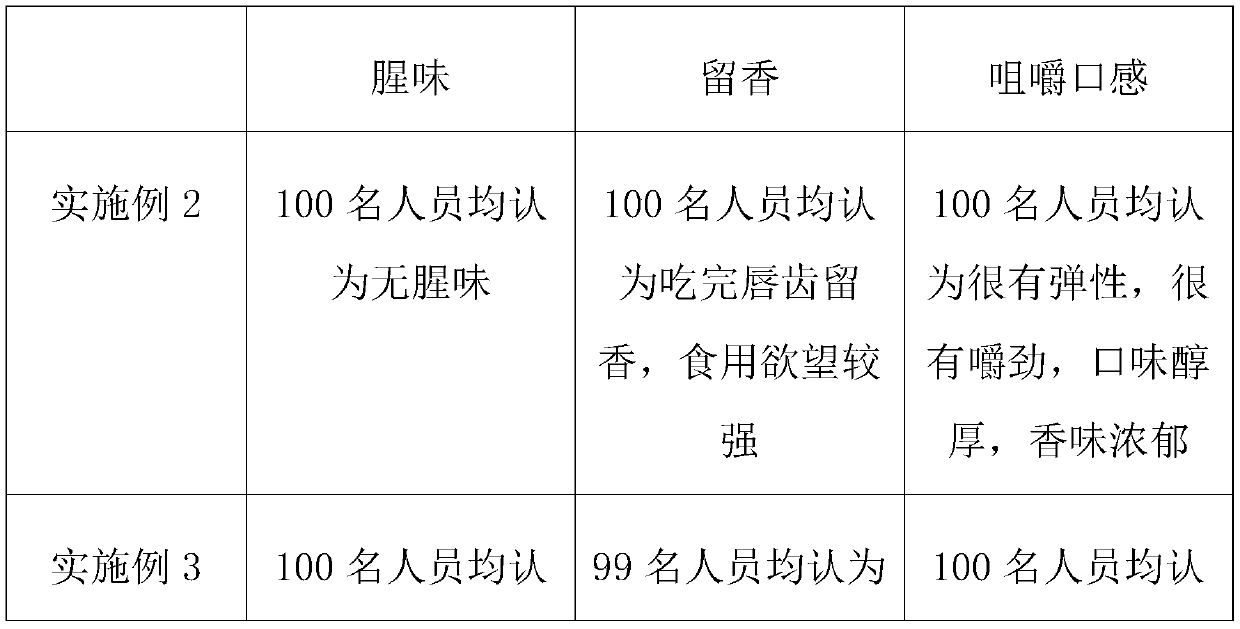

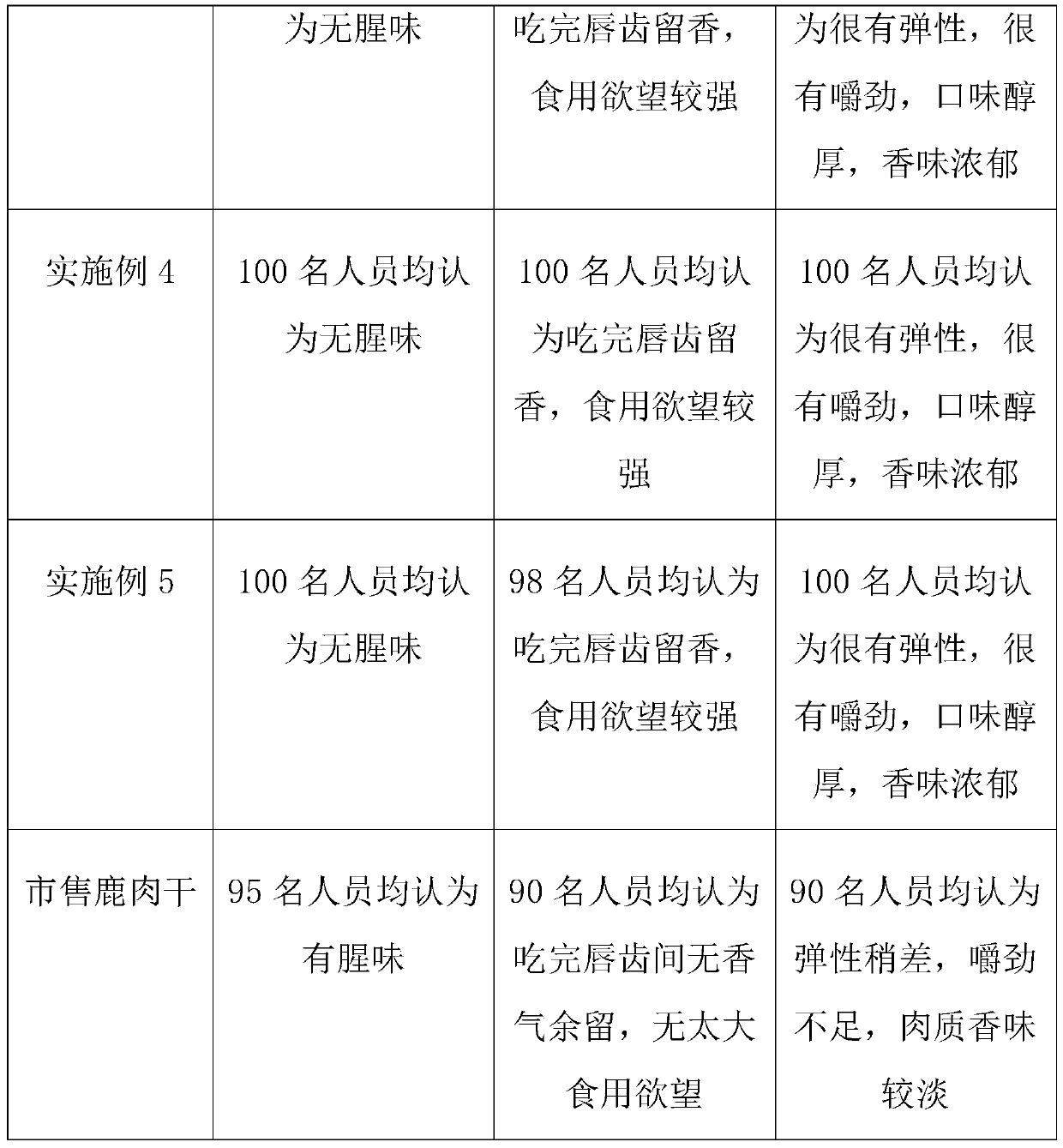

Examples

Embodiment 1

[0028] This embodiment provides a method for making dried venison without fishy smell, comprising the following steps:

[0029] S1: Pretreatment: Wash the fresh venison, soak it in clean water, and then take it out and cut it into pieces;

[0030] S2: Frying: Put the diced venison into a dry pan and stir-fry without oil during the process. Stir-fry until the venison shrinks and the edges of the venison are slightly burnt yellow, then pour it out and wait for it to cool ;

[0031] S3: Prepare materials: prepare appropriate amount of pepper and ginger, chop the ginger into a puree, and mix it with the pepper to obtain a mixture;

[0032] S4: Feeding: cutting several incisions on the surface of the venison obtained in step S2, and filling the incisions with an appropriate amount of mixture obtained in step S3;

[0033] S5: Stir-frying and steaming: put a small amount of oil in the pot, put the venison prepared in step S4 into the pot and continue to stir-fry, add oil while fryi...

Embodiment 2

[0038] This embodiment is further optimized on the basis of embodiment 1. Specifically, in step S1, the soaking time of fresh venison is 1 h, and the thickness of the cut pieces is 3 cm.

[0039] In step S5, the deodorizing auxiliary materials include the following materials by weight percentage: 20 parts of pepper, 5 parts of Chinese prickly ash, 20 parts of fennel, 10 parts of hawthorn, 10 parts of tangerine peel, 10 parts of angelica, 5 parts of licorice, 30 parts of star anise, salt 40 parts, white sugar 30 parts.

[0040] In step S5, the cooking time is 40 minutes.

[0041] In step S6, the flavoring auxiliary materials include the following materials by weight percentage: 25 parts of tomatoes, 15 parts of millet pepper, 5 parts of salt, 10 parts of ginger, 2 parts of Chinese prickly ash, 10 parts of garlic cloves, and 30 parts of water.

[0042] In step S6, the venison puree is marinated for 6 days.

[0043] In step S7, the drying temperature is 50° C., and the drying t...

Embodiment 3

[0046] This embodiment is further optimized on the basis of embodiment 1. Specifically, in step S1, the soaking time of fresh venison is 1.5 h, and the thickness of the cut pieces is 4 cm.

[0047] In step S5, the deodorizing auxiliary materials include the following materials by weight percentage: 22 parts of pepper, 7 parts of Chinese prickly ash, 25 parts of fennel, 12 parts of hawthorn, 12 parts of tangerine peel, 13 parts of angelica, 7 parts of licorice, 35 parts of star anise, salt 50 parts, white sugar 34 parts.

[0048] In step S5, the cooking time is 45 minutes.

[0049] In step S6, the flavoring auxiliary materials include the following materials by weight percentage: 27 parts of tomatoes, 18 parts of millet pepper, 8 parts of salt, 12 parts of ginger, 3 parts of Chinese prickly ash, 11 parts of garlic cloves, and 38 parts of water.

[0050] In step S6, the venison puree is marinated for 8 days.

[0051] In step S7, the drying temperature is 60° C., and the drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com