Modular foot-type single leg and cycloid planning method based on low reduction ratio motor technology

A technology of reduction ratio and modularization, which is applied in the field of modular footed single leg and control system, can solve the problems of low knee joint transmission efficiency, difficult motor torque control, unstable transmission torque, etc., and can solve synchronous belt slippage, position The effect of high control precision, easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

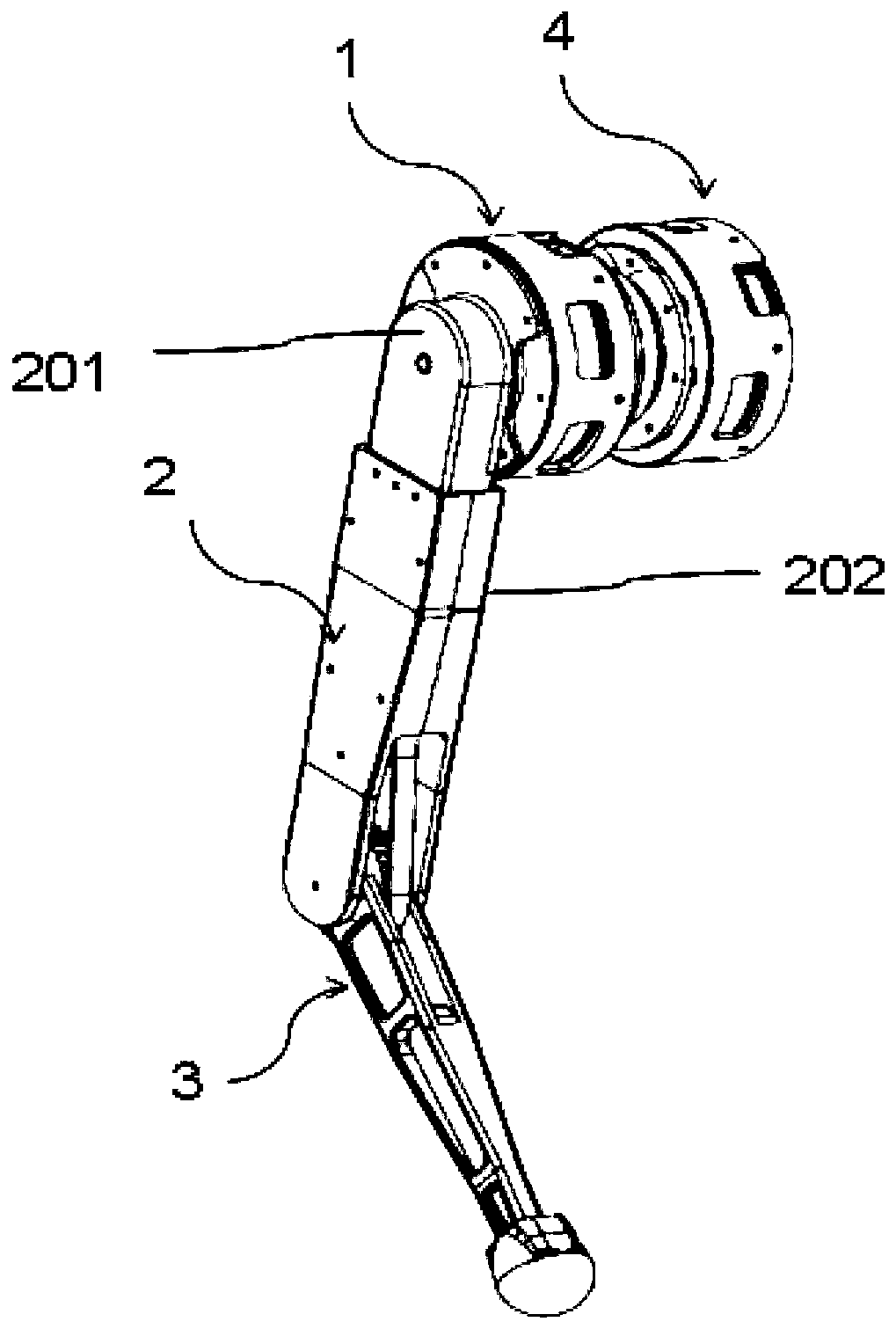

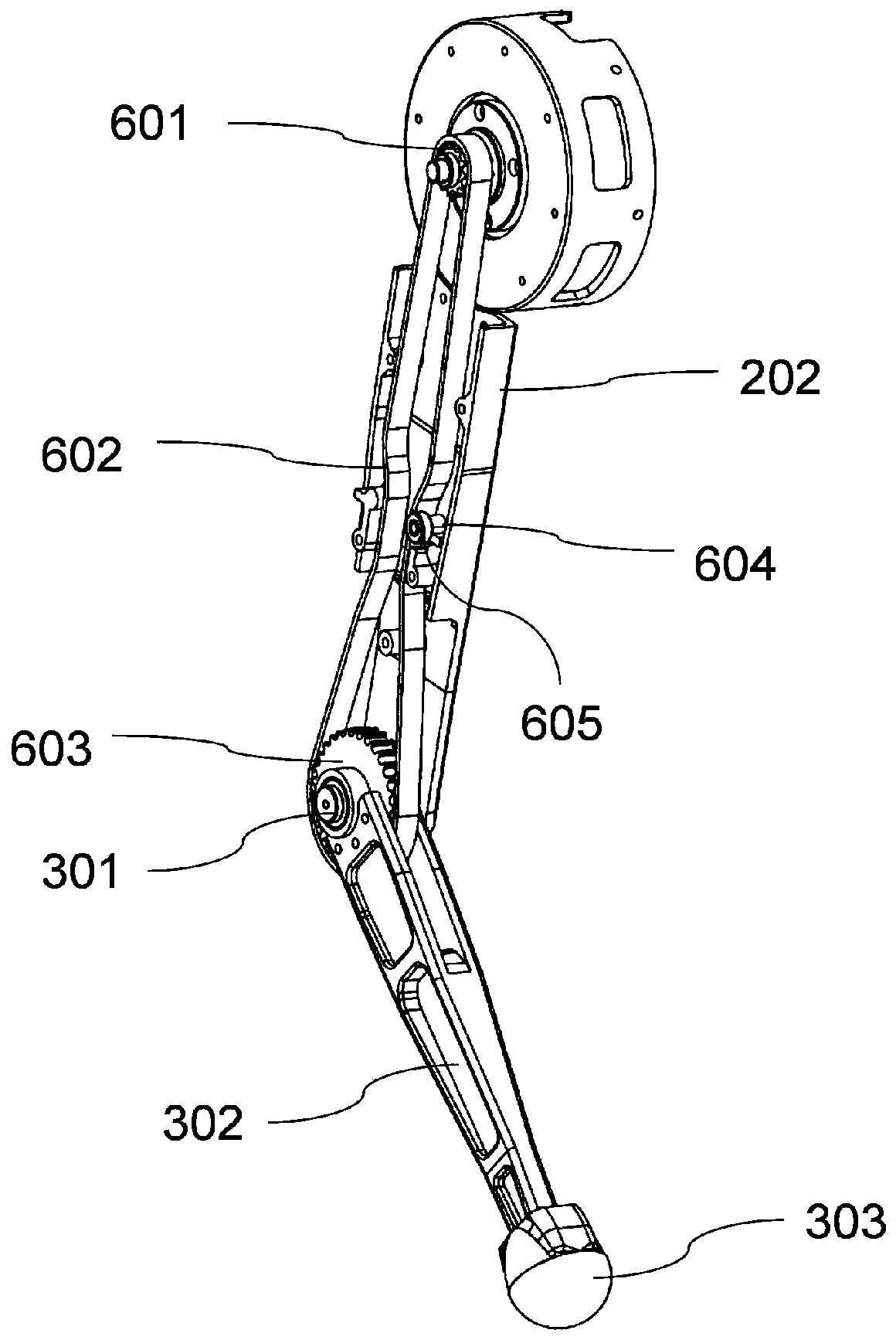

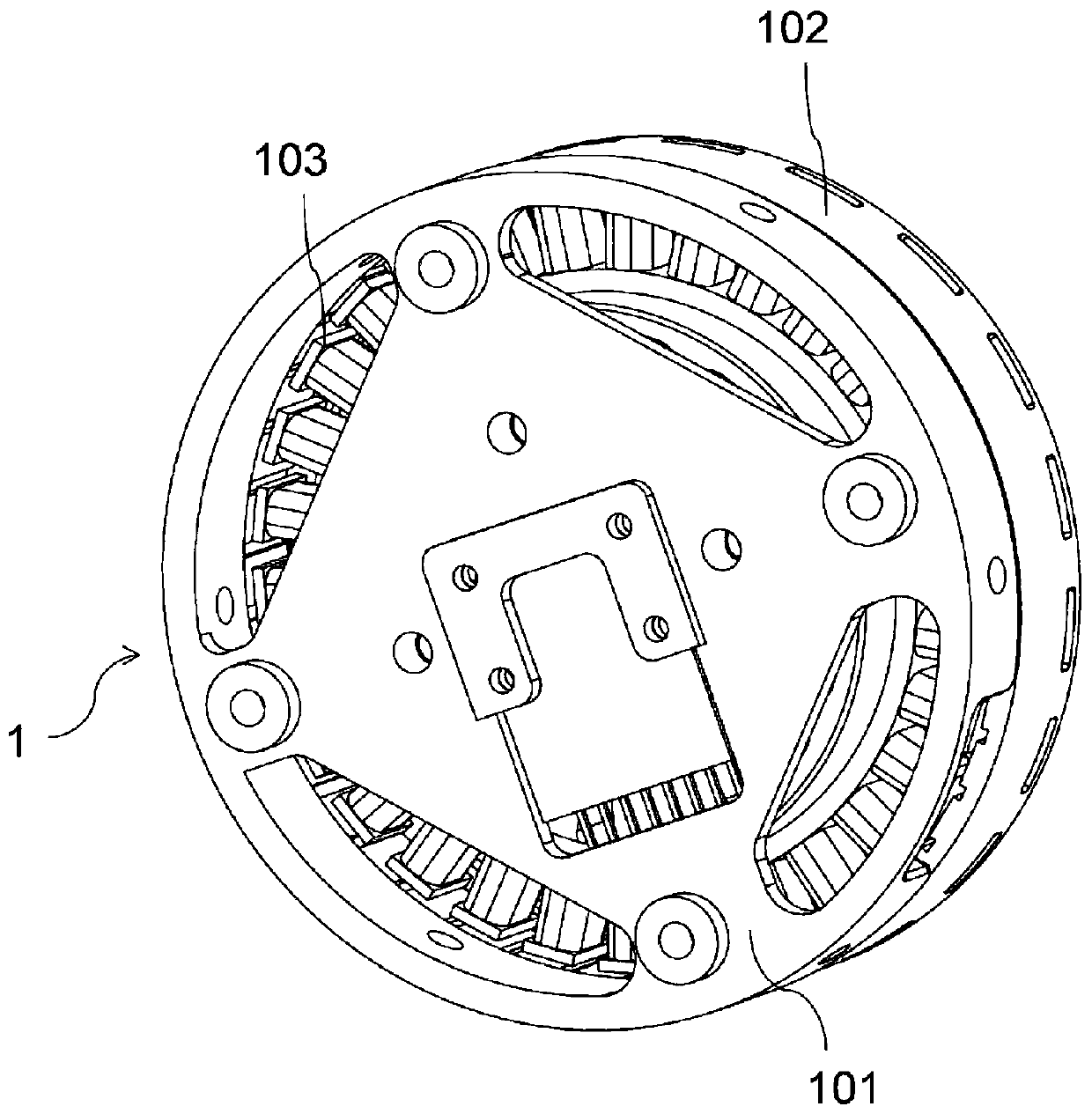

[0043] see Figure 1 to Figure 8 , a modular footed single leg based on low reduction ratio motor technology, which includes a hip joint drive module and a footed single leg; the footed single leg includes a knee joint drive motor 1, a thigh structure module 2, and a calf structure module 3. The thigh structure module 2 is flat as a whole. The thigh structure module 2 includes a thigh shell 201 and two thigh side plate shells 202. The thigh shell 201 constitutes the top of the thigh structure module 2. The two thigh side plate shells 202 are matched and installed to form a thigh structure module. 2, the bottom of the thigh structure module 2 is formed with a reserved hollow part, the hollow part is provided with a knee joint shaft 301, the thigh shell 201 and the two thigh side plate shells 202 are co-installed to form a cavity, and the transmission assembly is set In the cavity of the thigh structure module 2. The whole calf structure module 3 is also in a flat shape, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com