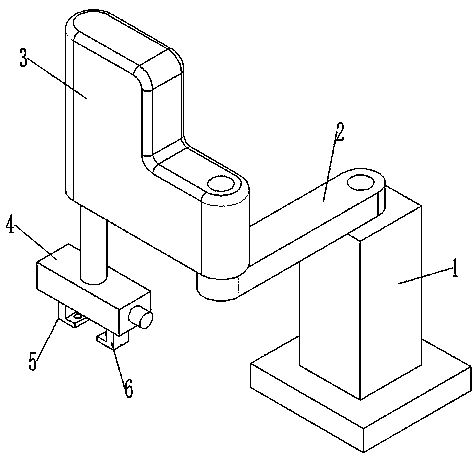

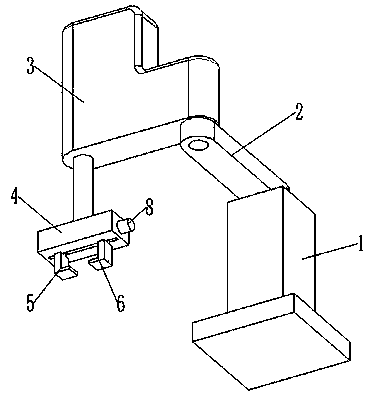

Automobile ECU quick testing device

A testing device and fast technology, applied in the directions of manipulators, program-controlled manipulators, chucks, etc., can solve the problems of unsatisfactory grasping effect and complex structure of circuit boards, improve grasping effect, expand swing range, and prevent falling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Refer below Figure 8 The basic composition of the automobile ECU of the embodiment of the present invention will be described.

[0032] In practical applications, due to the different configurations of the vehicles, the number of electronic control units is also different. Cars with low configuration and manual transmission generally have only one engine electronic control unit; cars with medium and high configuration, in addition to the engine electronic control unit, there are also automatic transmission electronic control units, anti-lock braking ABS electronic control units, and fully automatic air-conditioning electronic control units. Control unit, airbag electronic control unit, smart seat electronic control unit, central door control and other electronic control units, as many as a dozen, or even dozens of electronic control units. The composition mode of the electronic control unit on the car is the same, generally composed of sensors, ECU, and actuators.

...

Embodiment 2

[0049] Embodiment 2 is a further improvement to Embodiment 1.

[0050] In this embodiment, the testing device further includes a negative pressure generating device, which is electrically connected to the controller, that is, the controller can control the negative pressure of the negative pressure generating device.

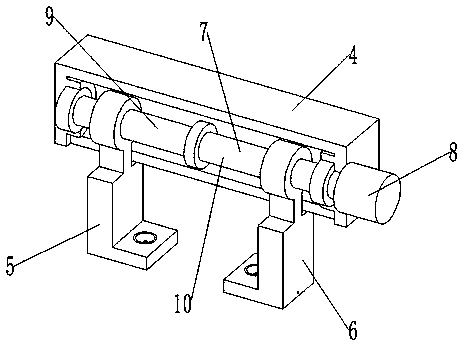

[0051] In this example, if Figure 5 with Image 6 As shown, the first clamping plate 5 is provided with a first accommodating cavity, and the first suction cup 19 is embedded and installed in the accommodating cavity. The first clamping plate 5 is provided with a first air hole 20, and the first air hole 20 is connected to the first air hole. The through hole 21 is connected, and the first air hole 20 is connected with the negative pressure generating device.

[0052] Specifically, the first clamping plate 5 is an L-shaped plate, the first clamping plate 5 has a first horizontal section and a first vertical section, the top of the first vertical section is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com