Automobile detection non-common-field-of-view camera global calibration system and method based on surface light field

A calibration system and common viewing technology, applied in the direction of measuring devices, optical devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

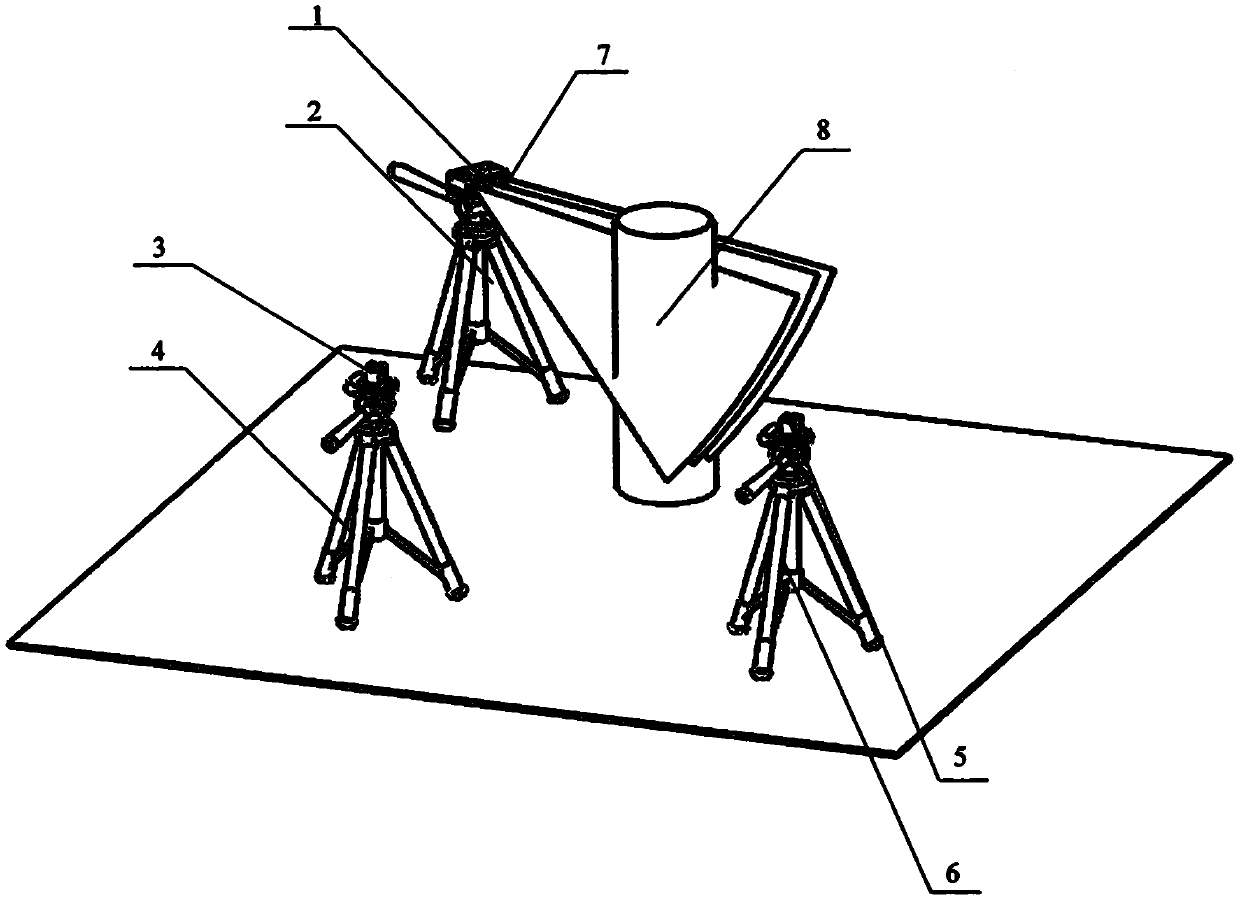

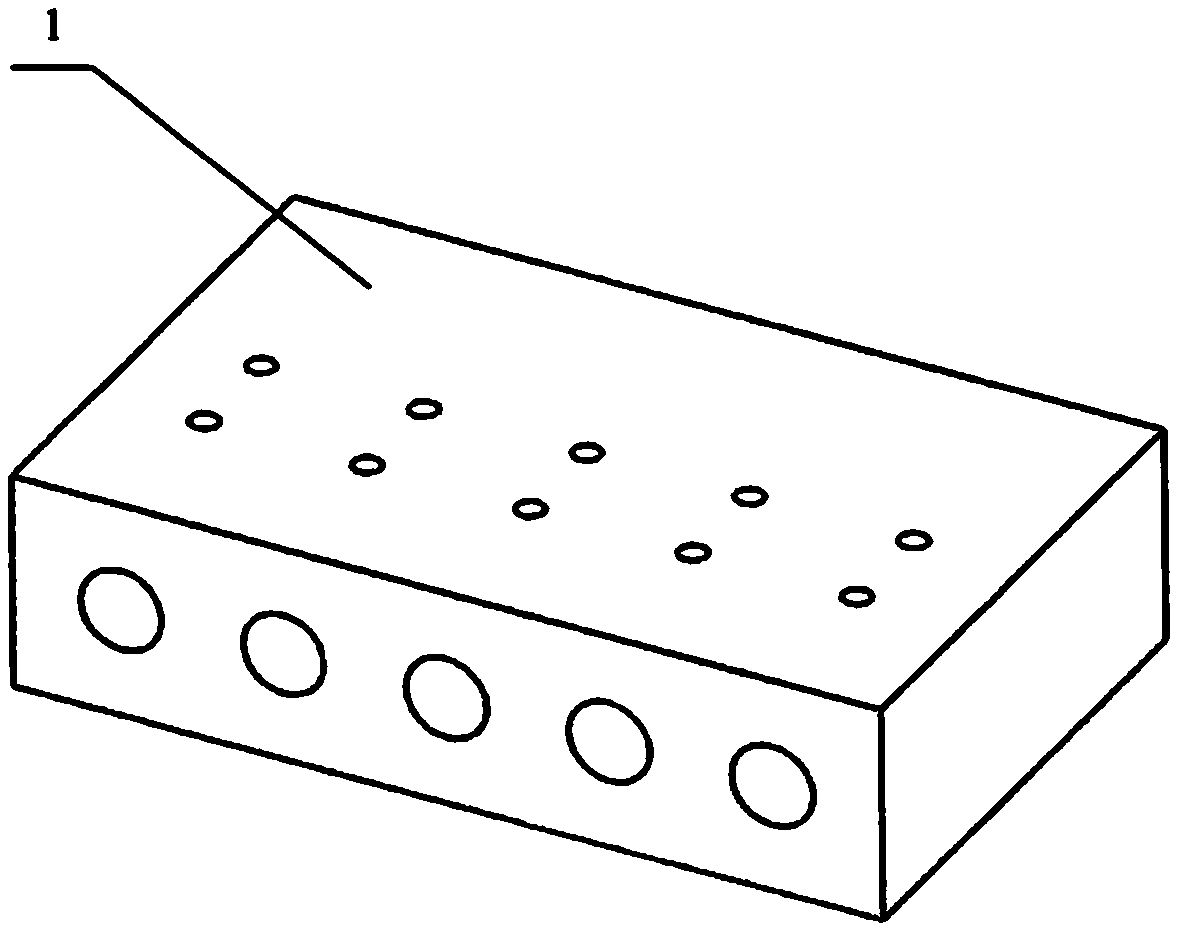

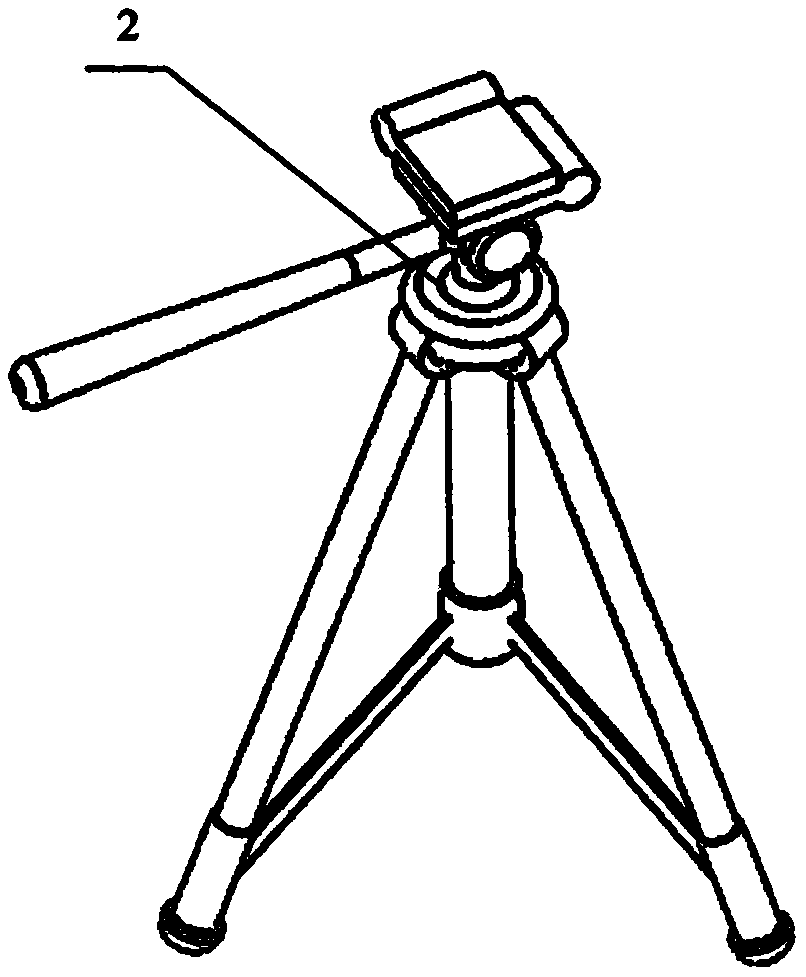

[0069] refer to Figure 1 to Figure 5 , the global calibration system of the car detection non-common field of view camera based on the surface light field includes a laser board box 1, a laser board box bracket 2, a left camera 3, a left camera bracket 4, a right camera 5, and a right camera bracket 6 , surface laser 7 and cylindrical target 8;

[0070] The laser board box bracket 2, the left camera bracket 4 and the right camera bracket 6 are all triangular brackets with adjustable height. The laser board box bracket 2, the left camera bracket 4, the right camera bracket 6 and the cylindrical target 8 are placed on the ground Above, the left camera 3 and the right camera 5 are wide-angle industrial cameras equipped with narrow-band filters, and the left camera 3 and the right camera 5 connect with the left camera bracket 4 and the right camera bracket through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com