Unitized assembly-type construction hanger capable of annularly sliding and used for storage tank construction

A prefabricated and unitized technology, which is applied to the scaffolding supported by the building structure, the accessories of the scaffolding, and the support of the building structure, etc., can solve the problems of difficult construction, inability to move the tank in a circular manner, time-consuming and laborious, and achieve flexible and convenient assembly. The installation method is simple and reliable, and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

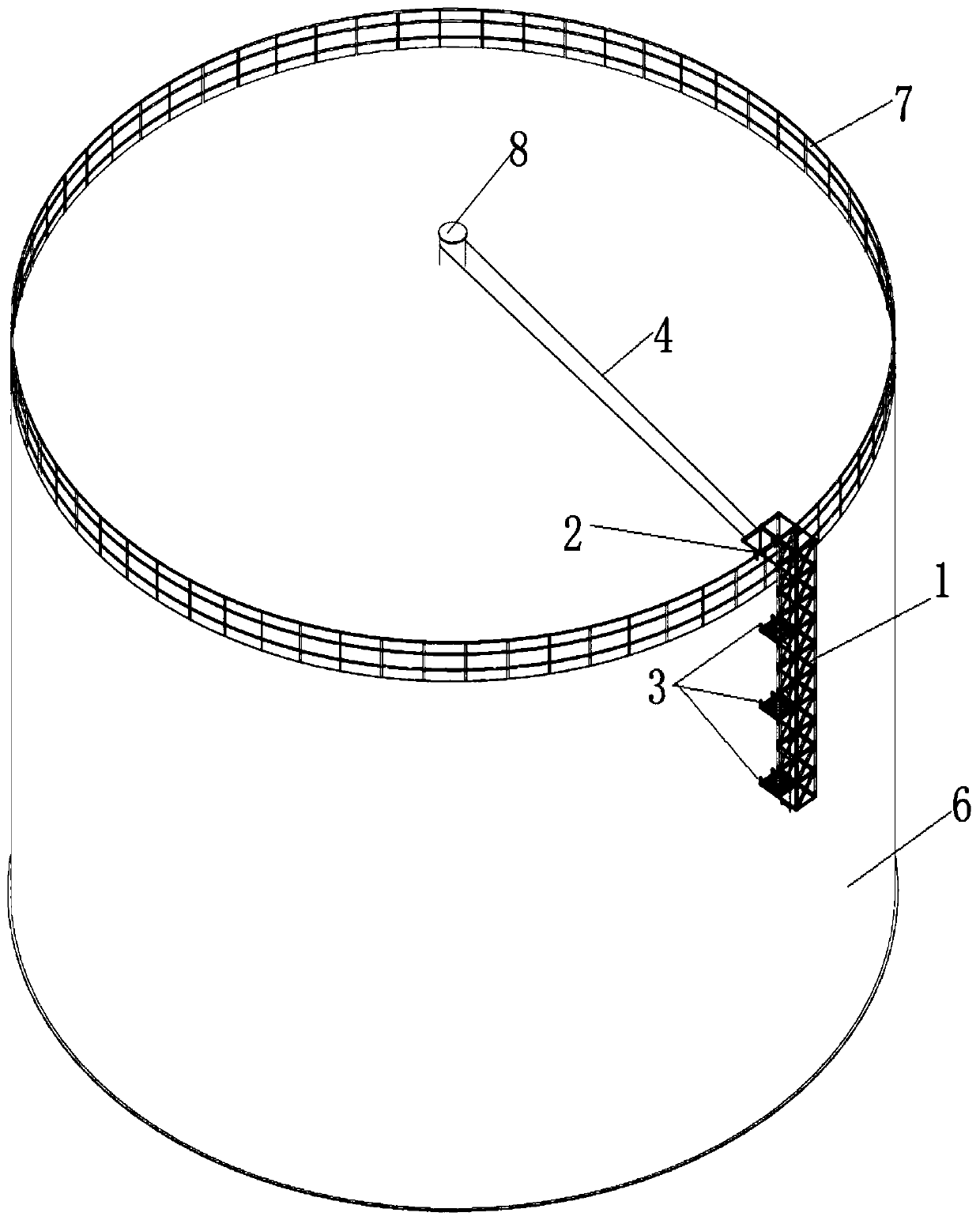

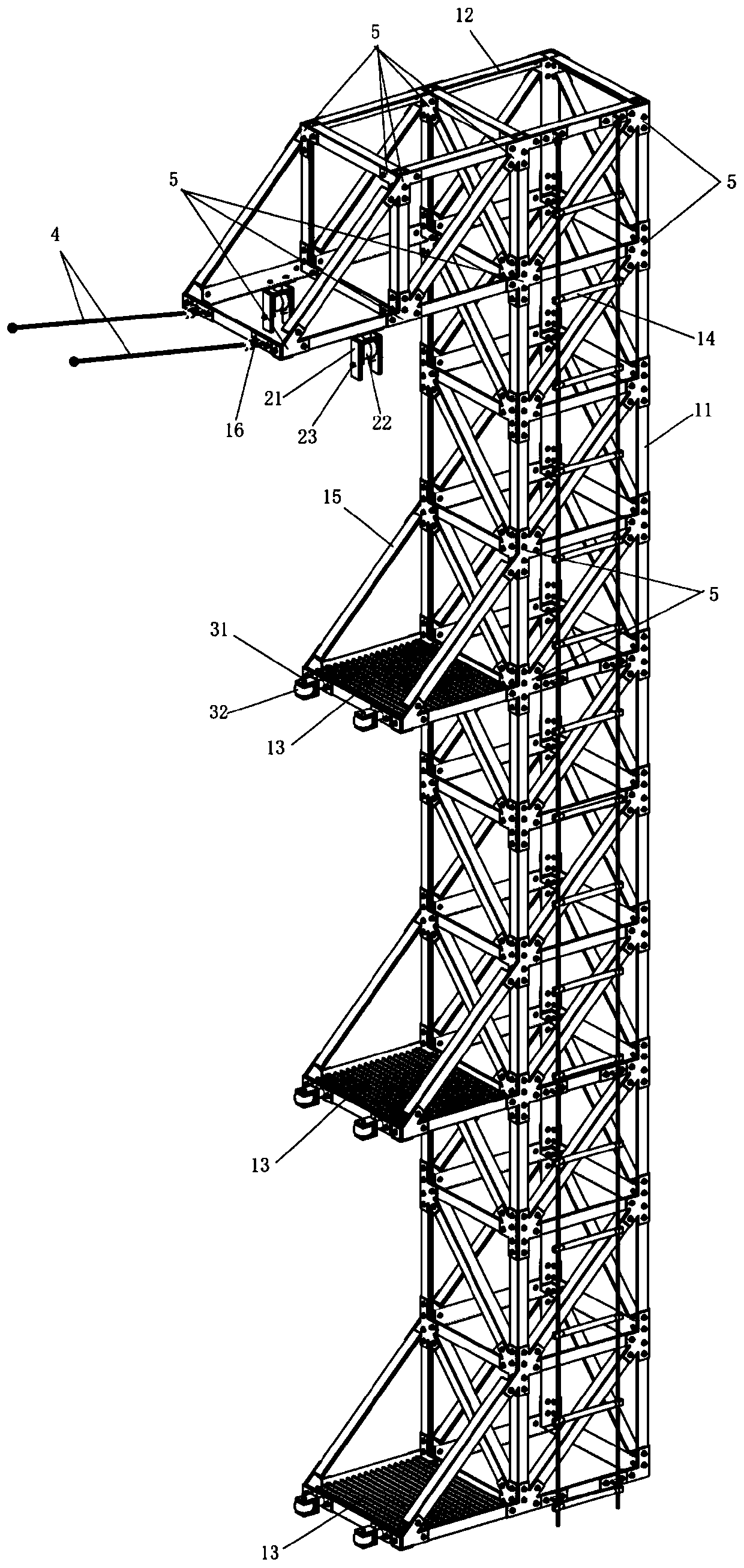

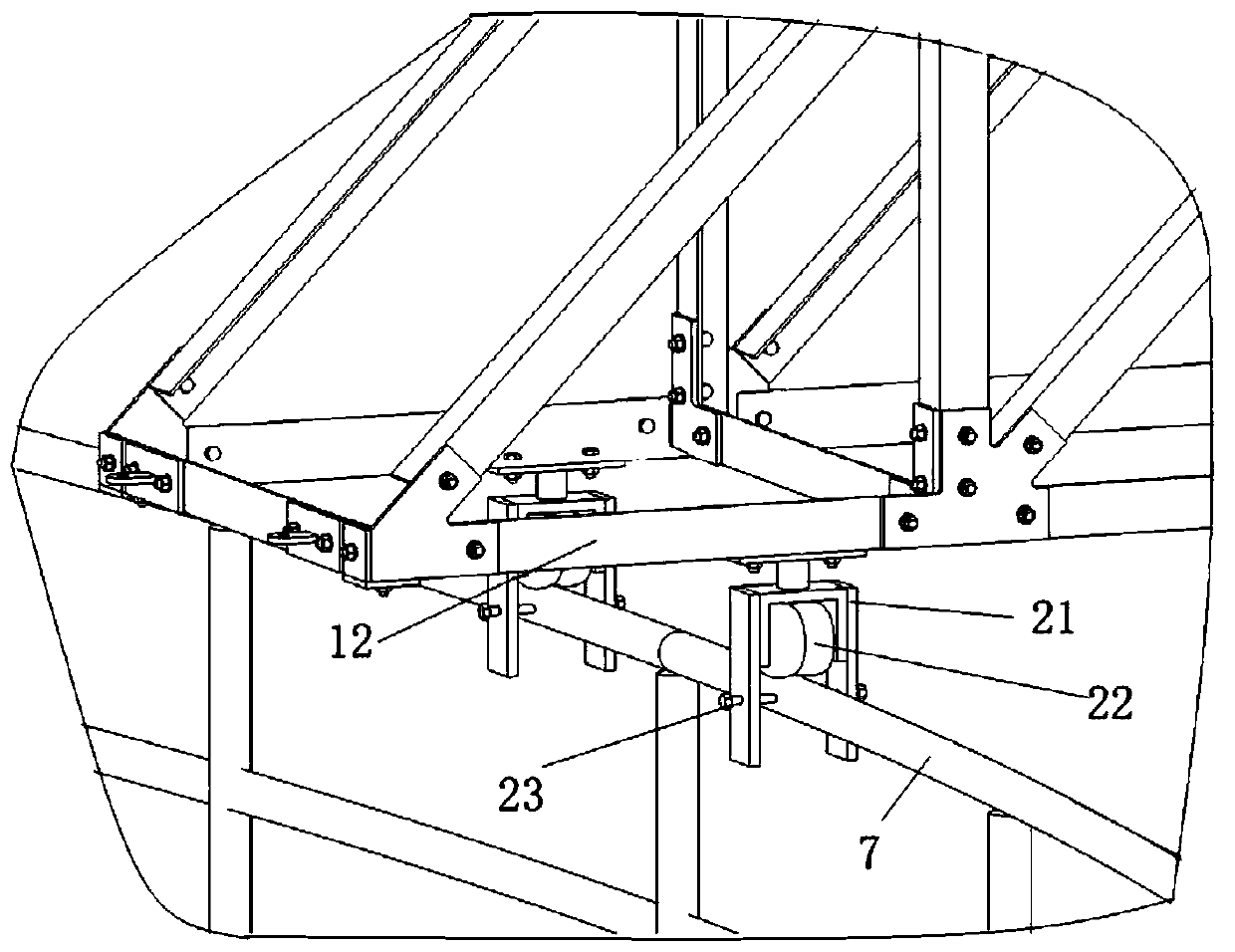

[0015] like figure 1 , figure 2 As shown, a unitized assembly type ring-slidable construction hanger for storage tank construction, including a cantilever ladder 1 with a truss structure assembled with angle steel, at least two cantilever bottoms installed on the ladder The vertical guide wheel assembly 2 on the ring fence 7 on the top of the tank and can slide along the fence, the horizontal guide wheel assembly 3 installed on the inner side of the vertical ladder of the climbing ladder and can roll along the circumference of the outer wall of the storage tank, and protrudes from the center of the top of the storage tank On the cylindrical structure 8 and both ends are connected to the stay rope 4 at the outer end of the ladder cantilever. The cantilever ladder 1 of the truss structure includes a stand 11, a horizontal cantilever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com