Multi-drill-rod hydraulic breaking hammer

A technology of hydraulic breaker and drill rod, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problems of time-consuming and hidden safety hazards, and achieve the effect of convenient switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

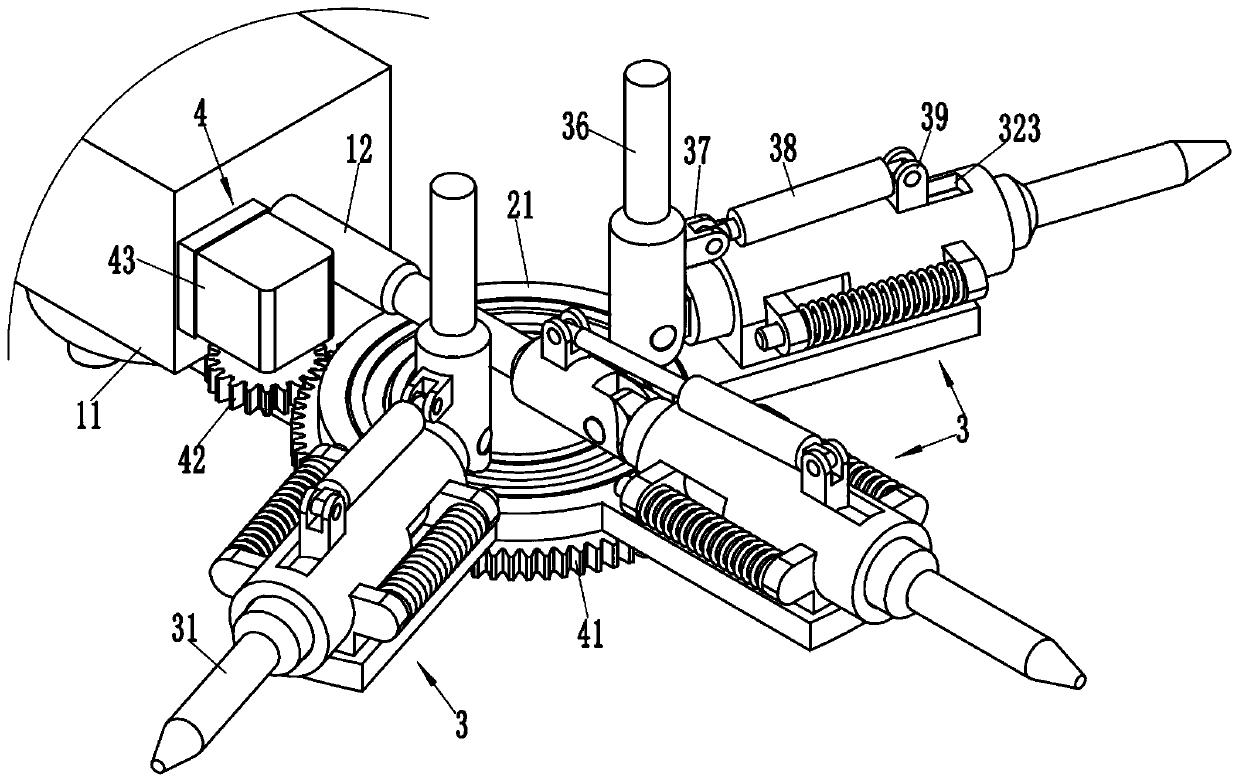

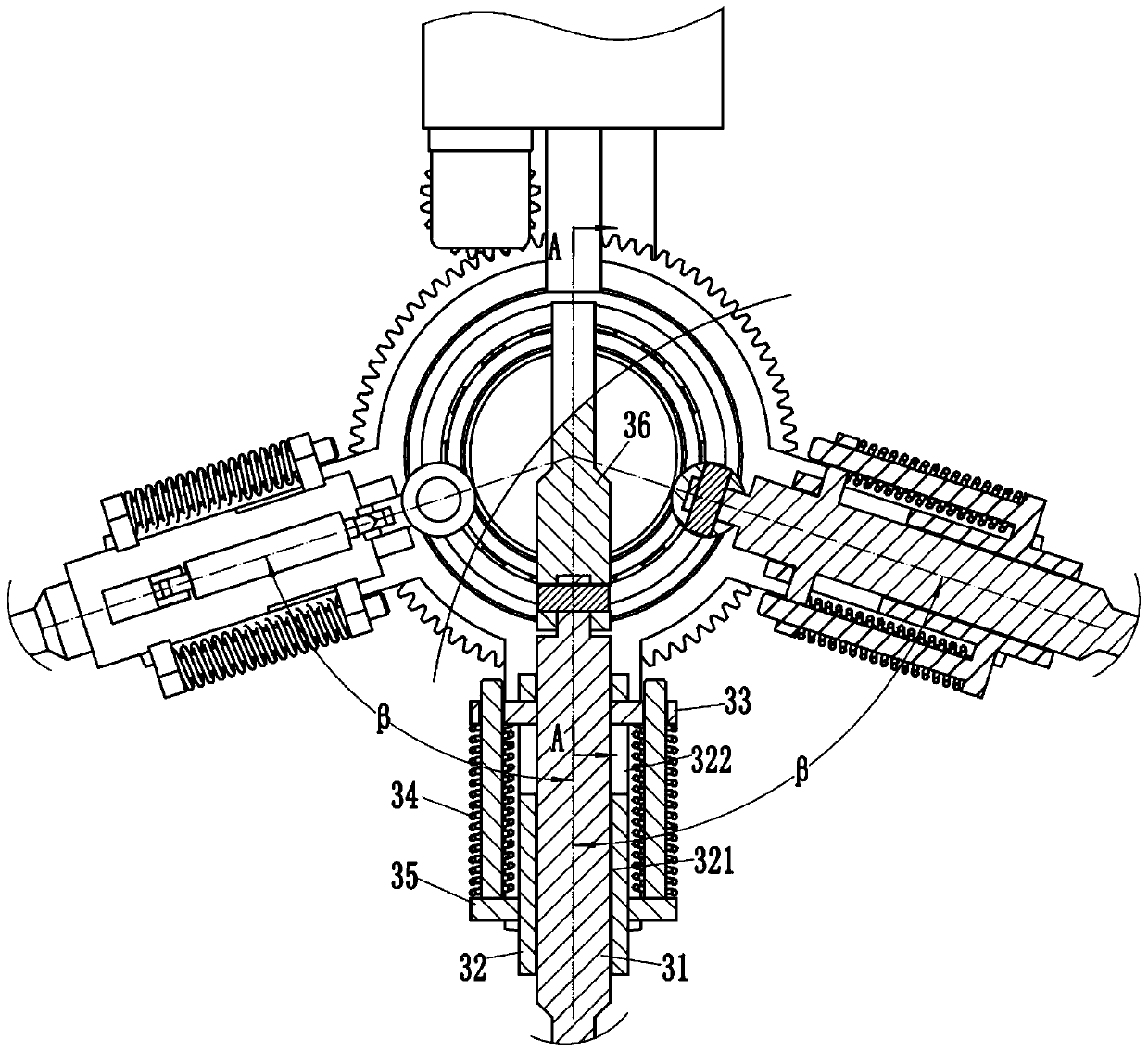

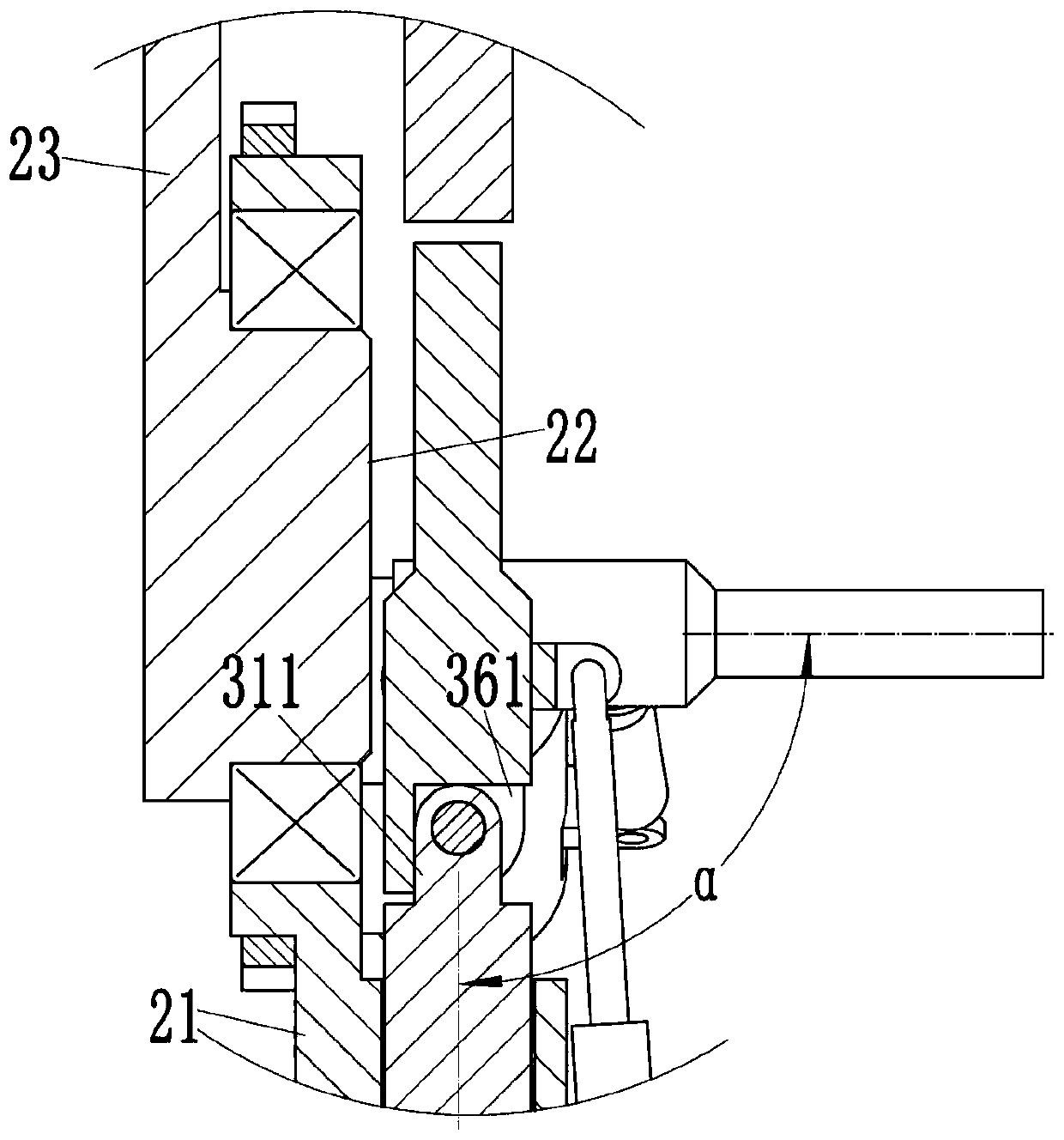

[0018] Example, see as Figure 1 to Figure 4 As shown, a hydraulic breaker with multiple drill rods includes a hammer body 11, the front end of the hammer body 11 is connected with an output drill rod 12, the front side of the output drill rod 12 is provided with a switching disc 21, and the switching disc 21 is hinged. On the hinge base 22, the hinge base 22 is fixedly connected to the hammer body 11 through the connecting arm 23, and the switching disc 21 is evenly distributed with three crushing actuators 3, the output drill rod 12 and one of the crushing actuators 3 The crushing drill rod 31 is arranged coaxially. The switching disc 21 is provided with a driving mechanism 4 to drive it to rotate. The driving mechanism 4 drives the switching disc 21 to rotate to switch between one of the other two crushing actuators 3 and the output drill. The rod 12 is connected.

[0019] Furthermore, the crushing actuator 3 also includes a crushing drill rod guide seat 32. The crushing dril...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap