Array type belt conveyor weighing device and installation process thereof

A technology of weighing device and installation process, applied in the direction of measuring device, weighing device testing/calibration, detailed information of weighing device, etc. Achieve the effect of reducing coplanarity requirements, reducing routine maintenance, and quick and effective calibration methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

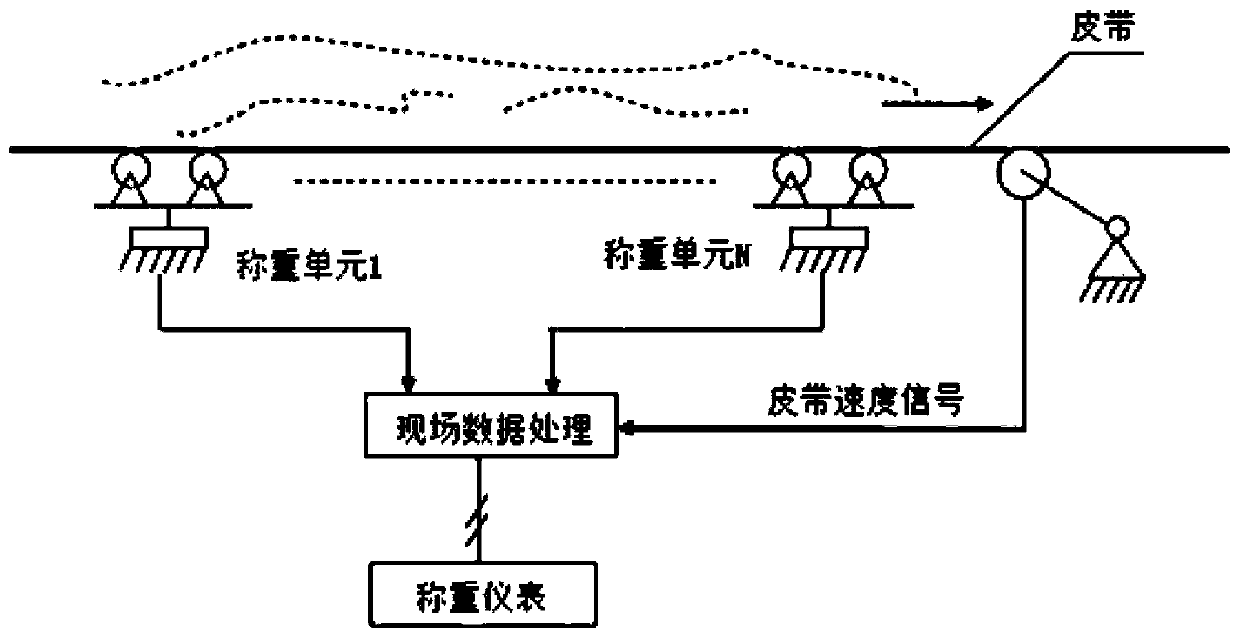

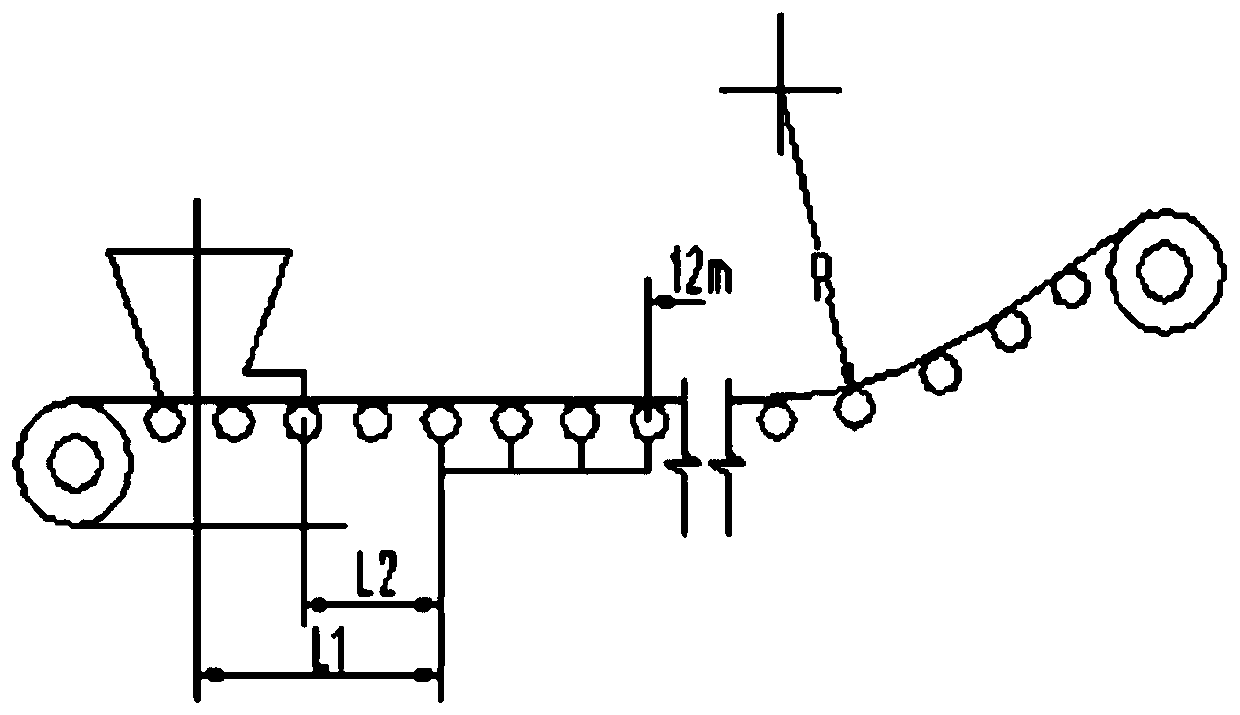

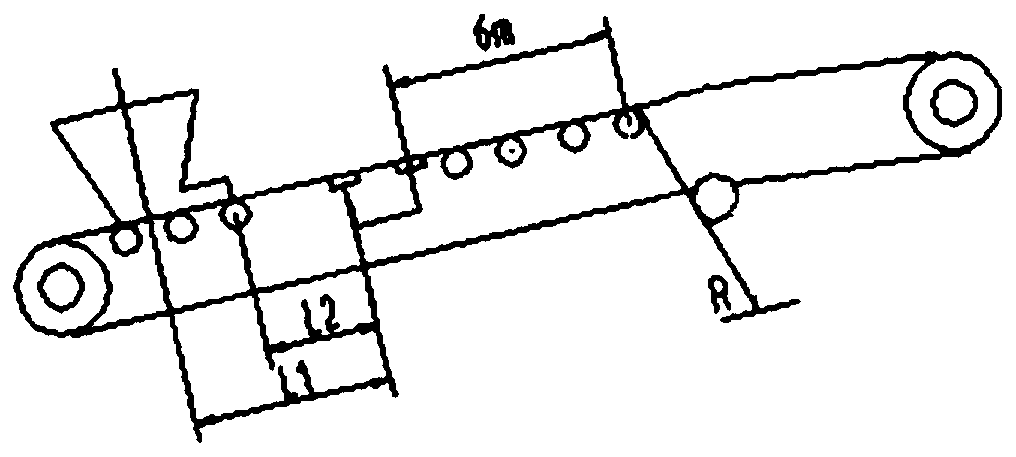

[0035] An array type belt conveyor weighing device, including a scale frame, a weighing instrument, a load cell and a speed sensor, the load cell and the speed sensor are suspended on the scale frame, and the weighing instrument is connected to the load cell and the speed sensor and directly Provide 5V voltage for the two sensors, the weighing sensor processes the weight signal into corresponding weight data and sends it to the weighing instrument. , weighing sensor and speed sensor constitute a single set of suspension weighing unit, and then multiple single sets of suspension weighing units are combined to form an array. When the material on the belt passes above the scale frame, the weight of the material is pressed against the sensor by the roller Above, the output signal of the sensor is proportional to the weight of the material, and it is converted into the average weight of the material on the unit belt length. At the same time, the speed sensor measures the running spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com