A prodigiosin-producing bacterium and its production method and application

A technology for prodigiosin and bacteria to produce prodigiosin is applied in the field of microbial fermentation, and can solve the problems of lowering prodigiosin fermentation production efficiency, difficulty in realizing continuous prodigiosin fermentation, large amount of organic solvent, and the like. Improved fermentation yield, good inhibitory effect, and short fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

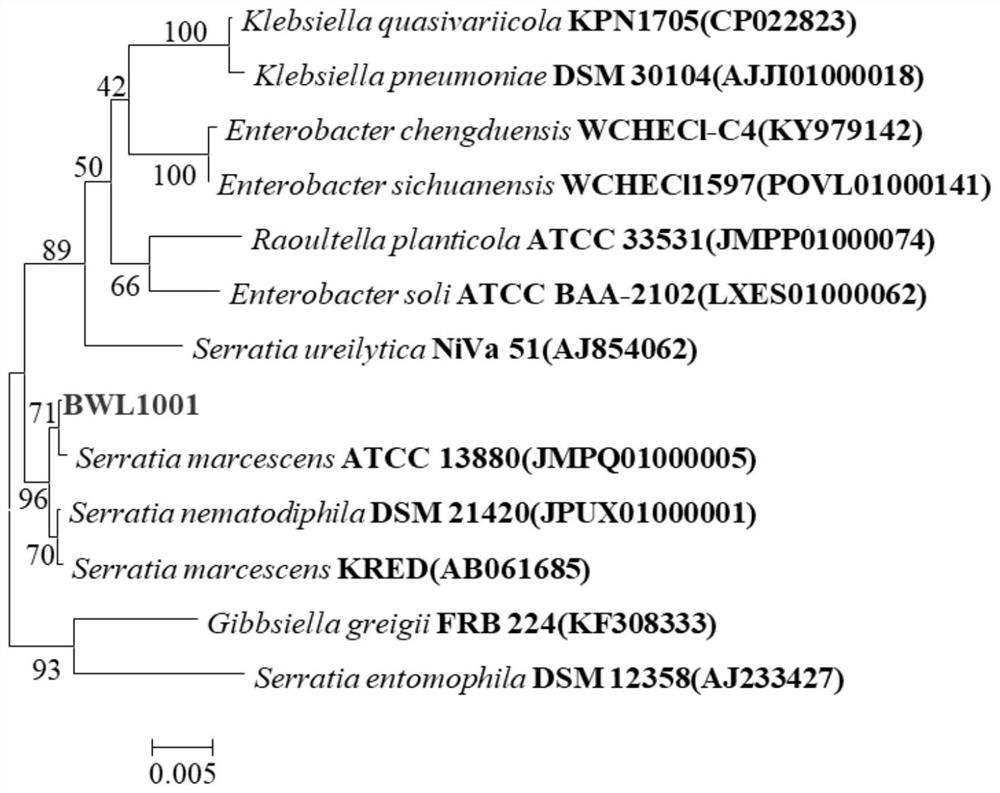

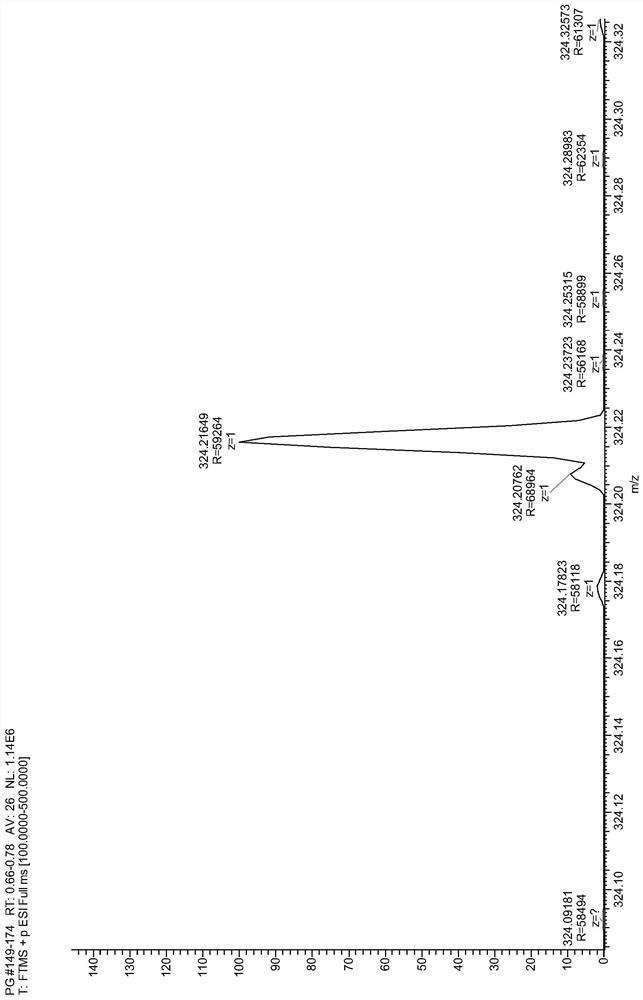

[0027] Isolation and identification of the bacterial strain BWL1001 of embodiment 1

[0028] 1.1 Isolation of strain BWL1001

[0029] Soil samples were collected from farmland in Tongshan District, Xuzhou City, Jiangsu Province.

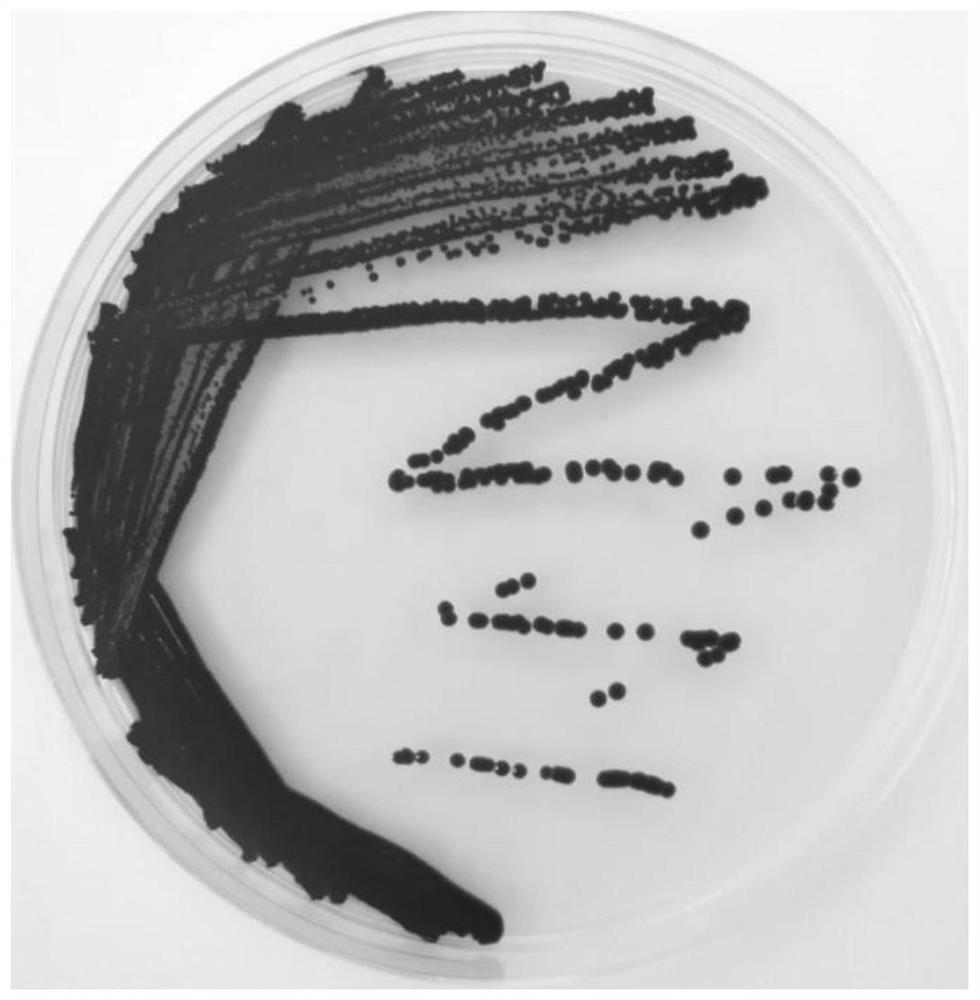

[0030] The collected soil samples were gradually diluted with 0.9% sterile saline, and then the dilutions were sequentially spread on the R2A solid medium (the composition of the R2A solid medium was as follows: soluble starch 0.5 g / L, glucose 0.5 g / L , yeast powder 0.5 g / L, tryptone 0.5 g / L, acid hydrolyzed casein 0.5 g / L, MgSO 4 •7H 2 O 0.05 g / L, K 2 HPO 4 0.3g / L, agar powder 20 g / L), put the coated medium upside down and put it in a constant temperature incubator at 28°C, and observe a red colony after culturing for 24 hours. After the strain was purified by the four-section line separation method, it was stored in a -80°C refrigerator with 20% glycerol solution.

[0031] 1.2 Strain identification

[0032] (1) Morphological identification ...

Embodiment 2

[0035] Example 2 Transformation of soybean oil production and in-situ extraction of prodigiosin

[0036] The specific implementation is as follows:

[0037] Step 1, preparation of seed solution: strain Serratia marcescens BWL1001 was inoculated into the seed liquid medium, and the components of the seed liquid medium were as follows: peptone 10 g / L, sodium chloride 10 g / L, magnesium sulfate heptahydrate 0.5 g / L, dipotassium hydrogen phosphate 0.3 g / L; 28°C, 200 rpm shaker constant temperature culture for 12-16 h;

[0038] Step 2, production of prodigiosin by fermentation: inoculate the seed liquid obtained in step 1 into the fermentation medium at a ratio of 1% (v / v), and the components of the fermentation medium are as follows: peptone 10 g / L, sodium chloride 10 g / L, magnesium sulfate heptahydrate 0.5 g / L, dipotassium hydrogen phosphate 0.3 g / L, soybean oil 10% (w / v); then 28°C, 200 rpm shaker constant temperature fermentation culture for 24-48 hours;

[0039] Step 3, in-...

Embodiment 3

[0043] The prodigiosin product obtained by fermentation was used for algal inhibition experiment analysis, in which Microcystis aeruginosa ( Microcystis aeruginosa ) were cultured in TAP liquid medium, and different concentrations (0.1 μg / mL, 0.2 μg / mL, 0.5 μg / mL, 1 μg / mL, 3 μg / mL) of prodigiosin were added, and after 48 h, the The concentration of algal cells in the culture medium. The calculation method of algae inhibition rate is as follows: (C0-Cp) / C0*100%, where C0 represents the concentration of algae cells in the culture medium without adding prodigiosin; concentration of algal cells.

[0044] The result is as Figure 4 As shown, it can be seen that the prodigiosin showed a good inhibitory effect on the growth of Microcystis aeruginosa, and when the product dosage of prodigiosin reached more than 1 μg / mL, Microcystis aeruginosa ( Microcystis aeruginosa ) has an algae inhibition rate of more than 80%, indicating that the prodigiosin product can be used to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com