Stacking mechanism for palletizing packaging boxes

A packaging and palletizing technology, which is applied in the field of continuous stacking processing of packaging boxes, can solve the problems of high use cost, prone to failure, and packaging box rollover damage, etc., and achieves reasonable structure design, stable and accurate translational discharge, stable The effect of accurate translational feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

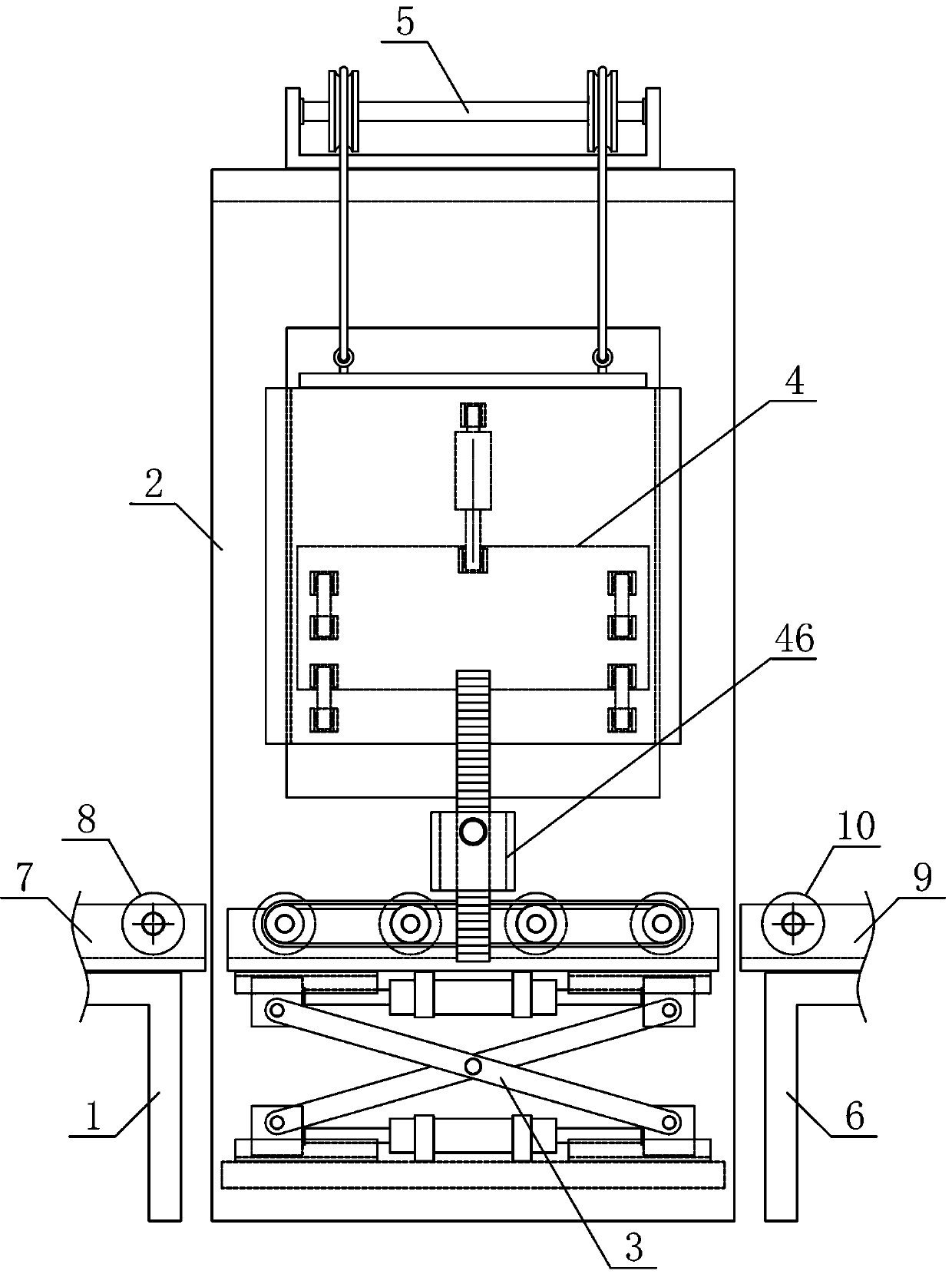

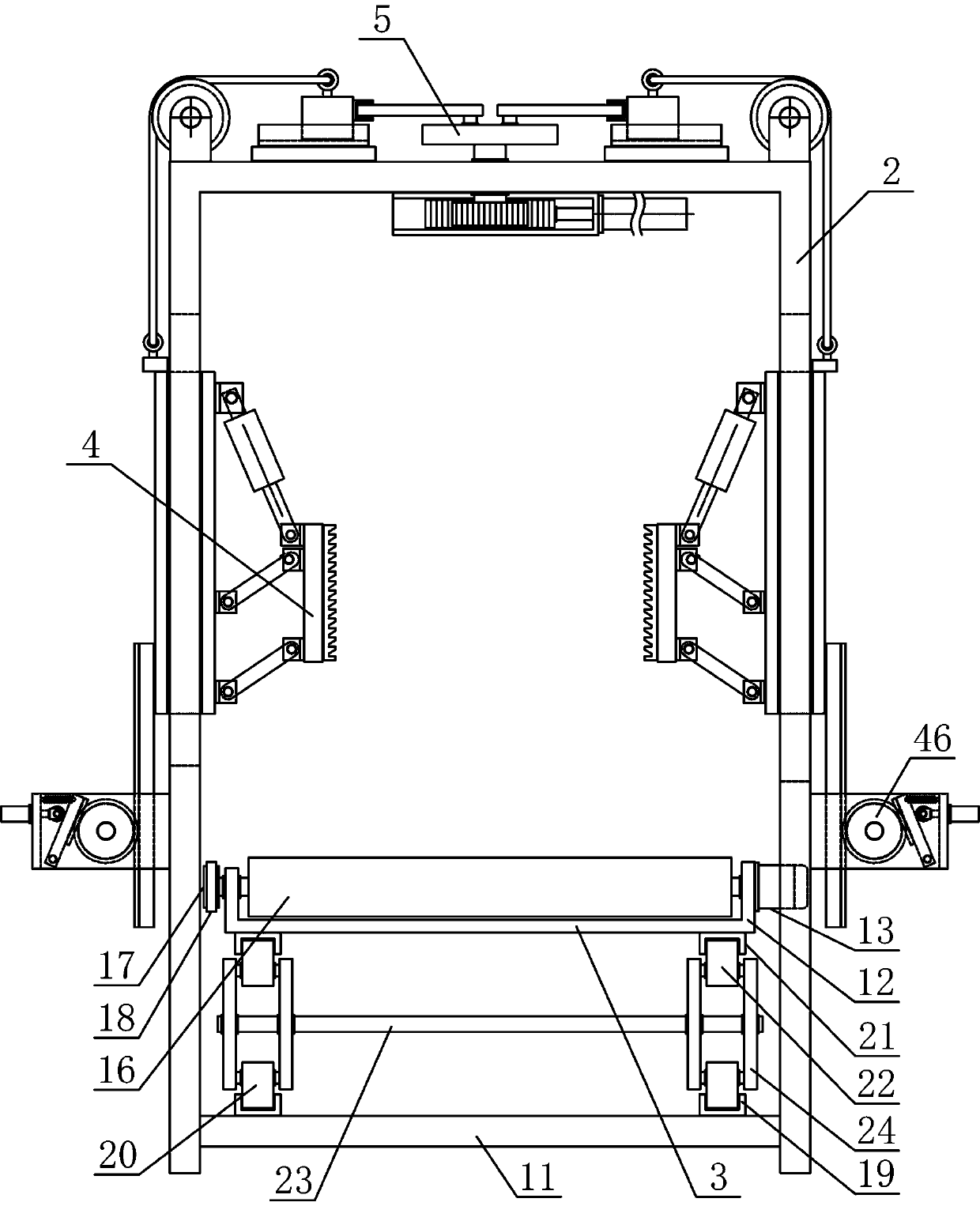

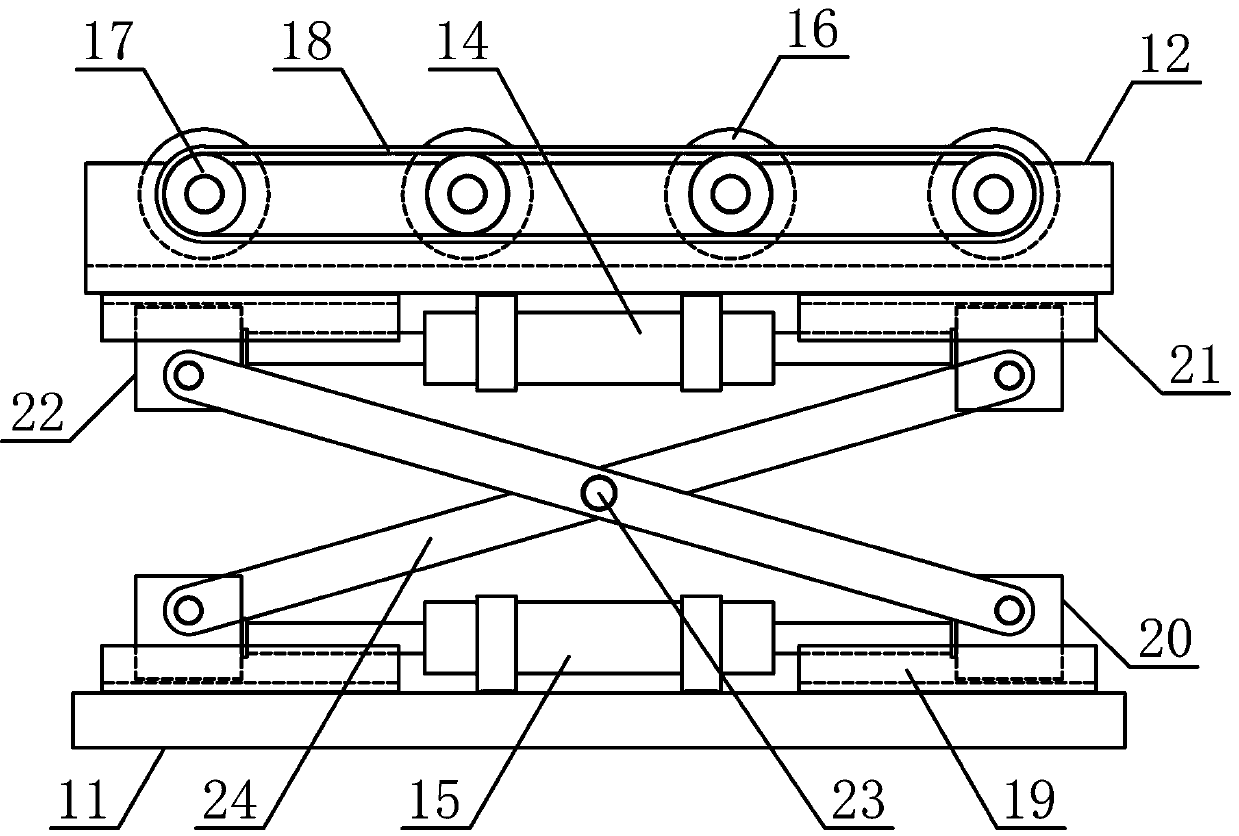

[0020] In order to further describe the present invention, a specific implementation of a stacking mechanism for palletizing packaging boxes will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0021] like figure 1 and figure 2 As shown, the present invention is a kind of stacking mechanism that is used for packing box palletizing, comprises storage box feeding support 1, storage box stacking support 2, storage box elevating mechanism 3, clamping box fixing mechanism 4, lifting adjustment mechanism 5 and storage box The discharge support 6, the storage tank feed support 1, the storage tank stacking support 2 and the storage tank discharge support 6 of the present invention are fixedly arranged sequentially along the horizontal conveying direction of the packing box, and the upper side of the storage box feed support 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com