Ceramic mold uniform grouting frame

A ceramic mold, uniform technology, applied in the field of grouting racks, can solve the problems of troublesome operation and low work efficiency, and achieve the effect of convenient operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

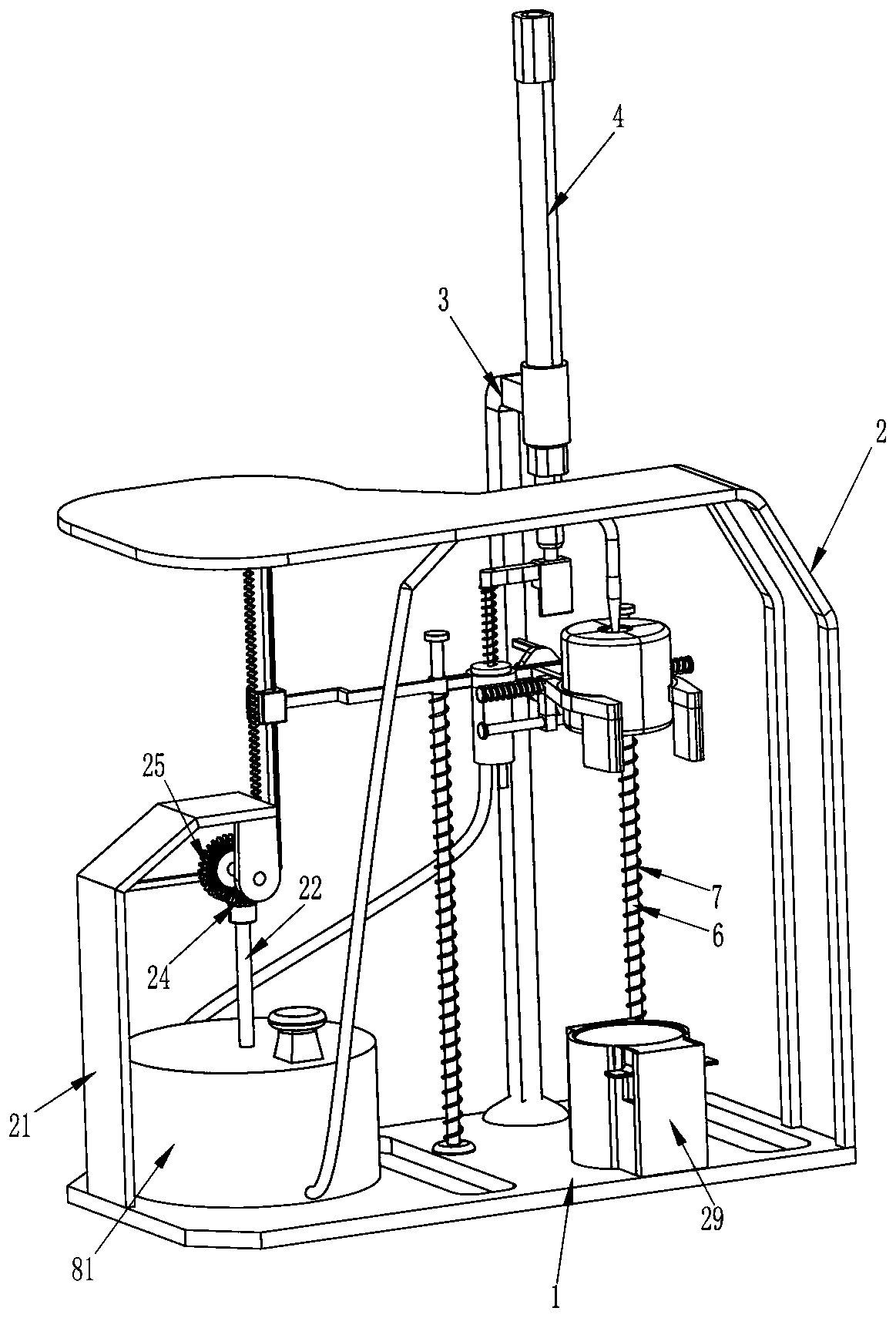

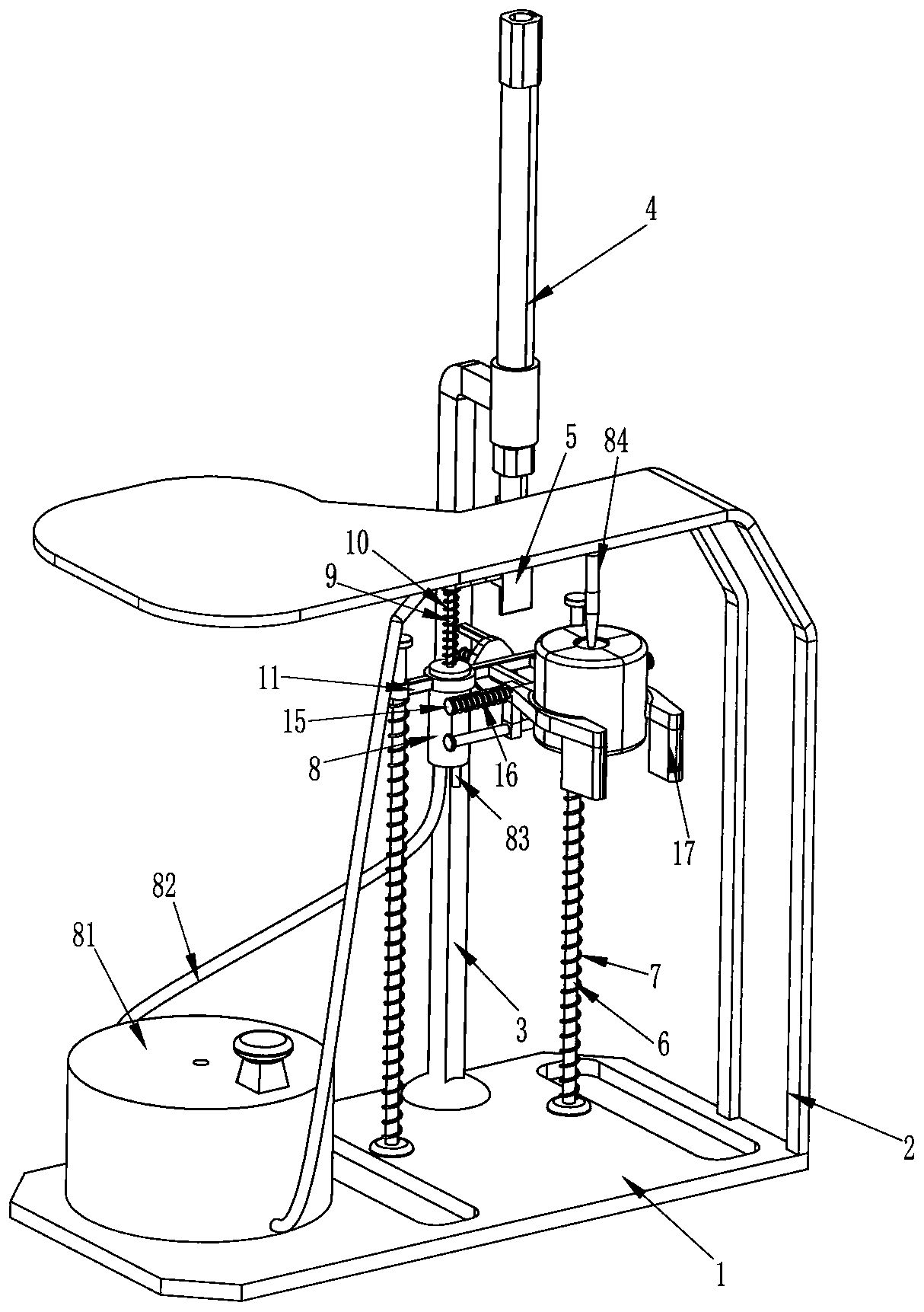

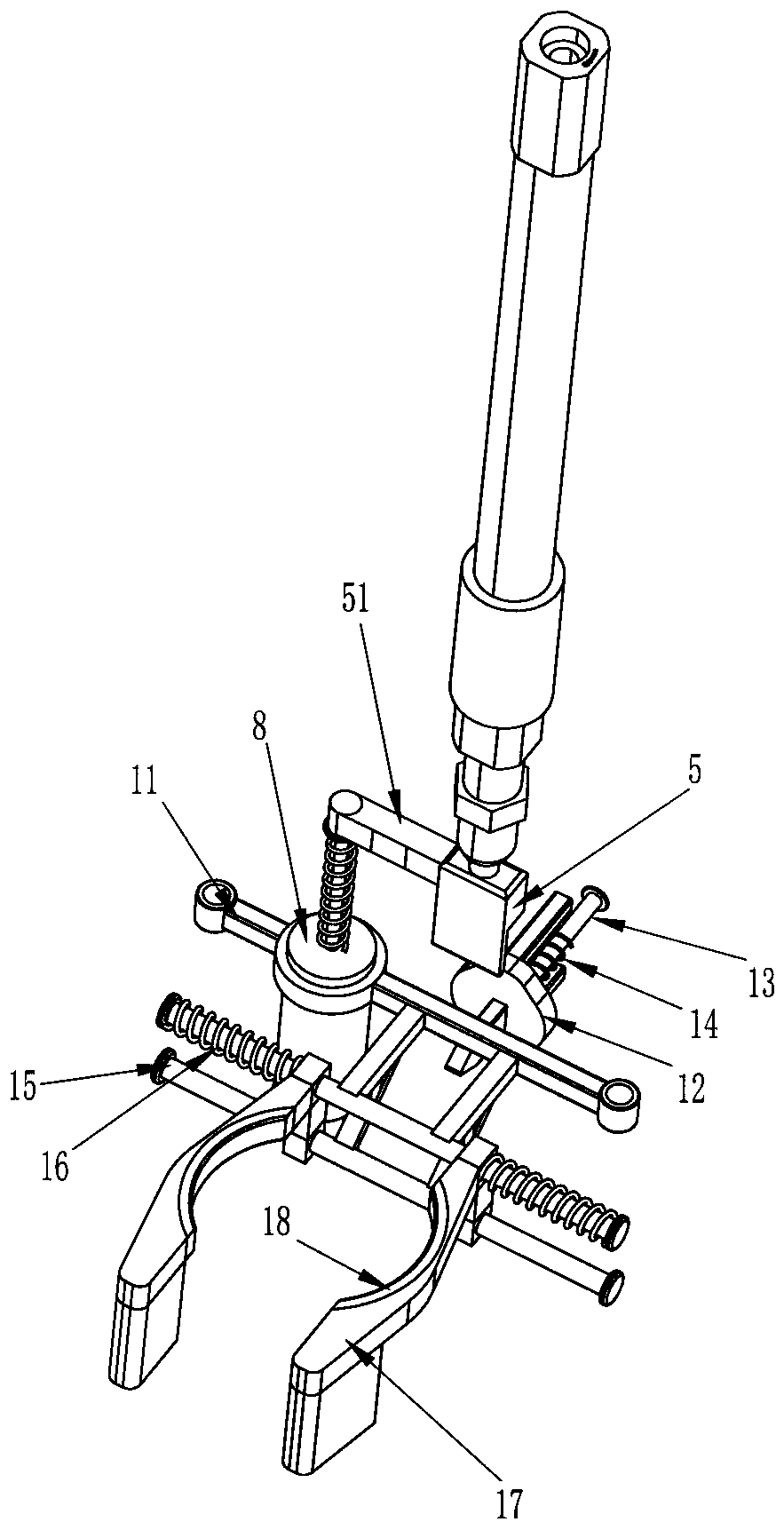

[0024] see Figure 1-Figure 3 , a uniform grouting frame for ceramic molds, including a base 1, a frame 2, a support rod 3, a cylinder 4, a driving mechanism, a charging box 81, a grouting pipe 84 and a clamping mechanism, and the front part on the right side of the top of the base 1 is fixed Connected to the frame 2, the top right side of the frame 2 is fixedly connected with a spray pipe 84, the top left side of the base 1 is installed with a charging box 81, and the lower part of the front side of the charging box 81 is connected and communicated with one end of the spray pipe 84 , the rear part of the right side of the top of the base 1 is fixedly connected with a support rod 3, and the rear end of the support rod 3 is fixedly connected with a cylinder 4, and the right side of the top of the base 1 is provided with a drive mechanism, which is connected with the telescopic rod of the cylinder 4, and the drive mechanism is also connected with the telescopic rod of the cylinde...

Embodiment 2

[0031] see figure 1 , Figure 4 and Figure 5 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, it also includes a guide sleeve 19, a rack 20, a fixed frame 21, a connecting plate 211, a rotating shaft 22, a stirring plate 23, a straight bevel gear 24, Two-way special-shaped gear 25, folding lever 26, wedge-shaped block 27 and the fifth spring 28, base 1 top left rear part is fixedly connected with fixed frame 21, and fixed frame 21 inner top right front part is fixedly connected with connecting plate 211, connecting plate 211 bottoms are rotatably connected with bidirectional special-shaped gear 25, and the middle rotatable of charging box 81 top is connected with rotating shaft 22, and the bottom end of rotating shaft 22 is affixed with agitating plate 23, and the top of revolving shaft 22 is affixed with straight-toothed bevel gear 24. The bevel gear 24 is located at the front side of the two-way special-shaped gear 25 and mesh...

Embodiment 3

[0034] see figure 1 and Figure 6 , compared with embodiment 1 and embodiment 2, the main difference of this embodiment is that in this embodiment, it also includes a placement block 29, a support plate 30, a sixth spring 31, an L-shaped rotating block 32 and a torsion spring 33, and the base 1 The front part on the right side of the top is fixedly connected with a placement block 29, and a sliding support plate 30 is provided in the placement block 29. A sixth spring 31 is connected between the bottom of the support plate 30 and the inner bottom of the placement block 29, and the left and right sides of the placement block 29 Both sides tops are all hinged with L-shaped rotating block 32, and the hinge of L-shaped rotating block 32 and placement block 29 is provided with torsion spring 33.

[0035] When the clamp block 17 drives the mold to move downward, the mold moves downward to contact the support plate 30. Due to the action of the sixth spring 31, the support plate 30 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com