Auxiliary frame of special electric vehicle

A sub-frame and special-purpose vehicle technology, which is applied in the field of electric special-purpose vehicle sub-frame, can solve the problems of affecting pedestrians, vehicle passing, time-consuming and laborious, low efficiency, etc. The effect is more reasonable and the stability is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

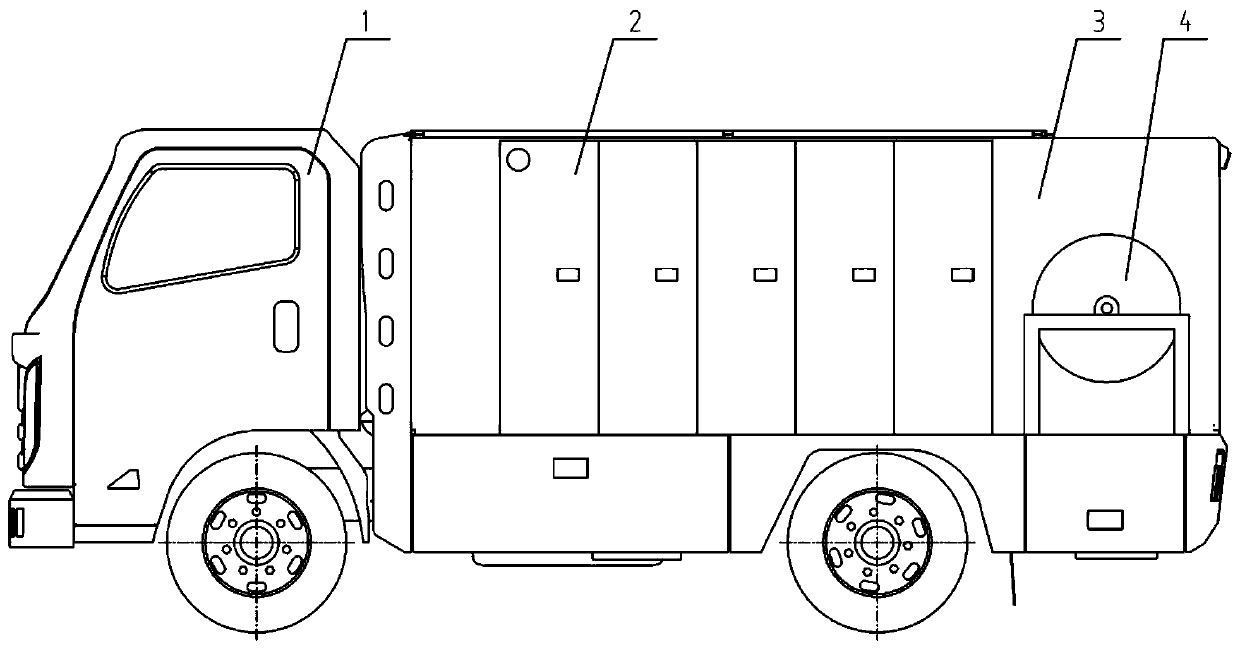

[0023] The technical solutions in the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. For ease of description, the figure 1 The left side in is defined as front, and the right side is defined as back.

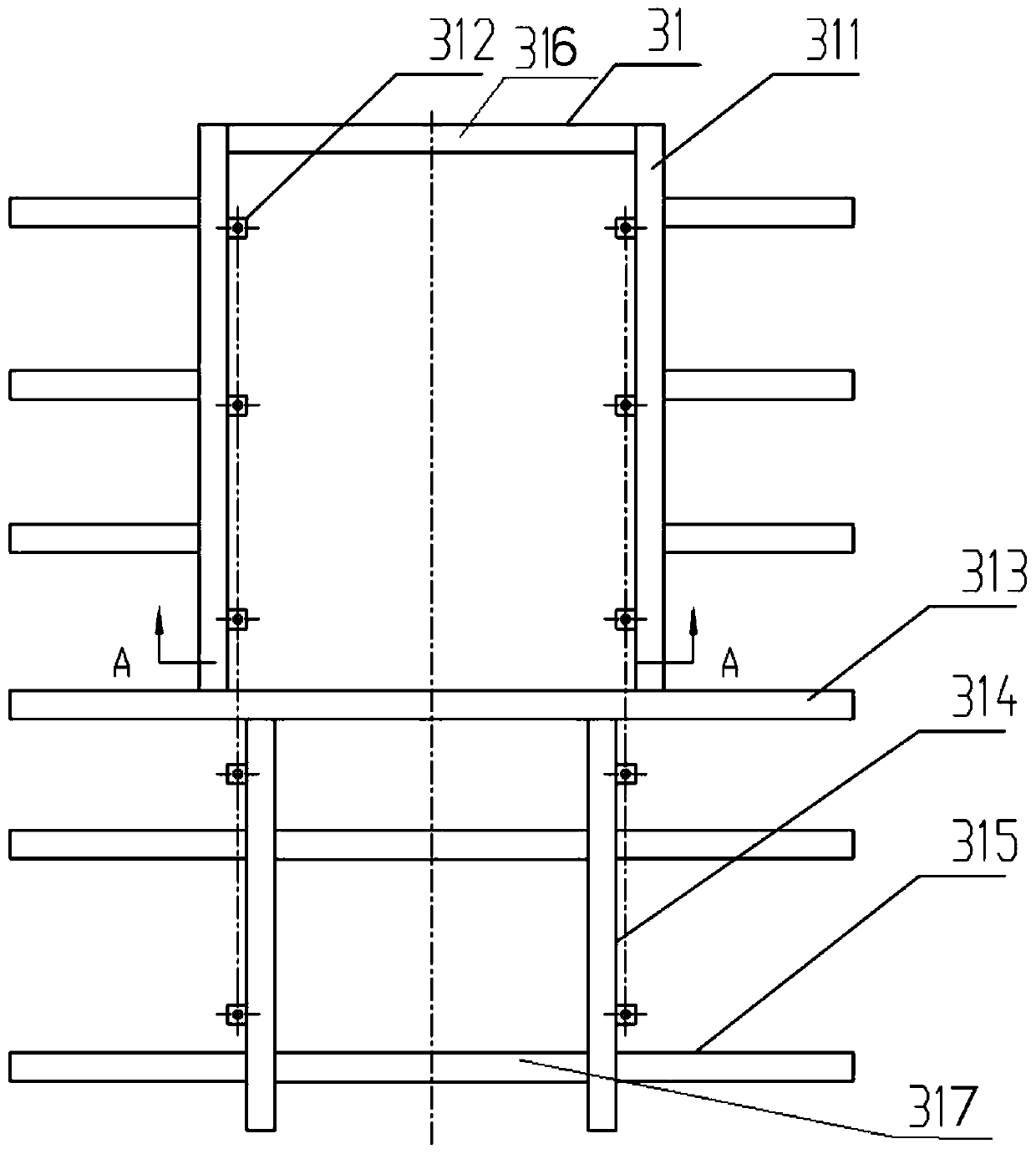

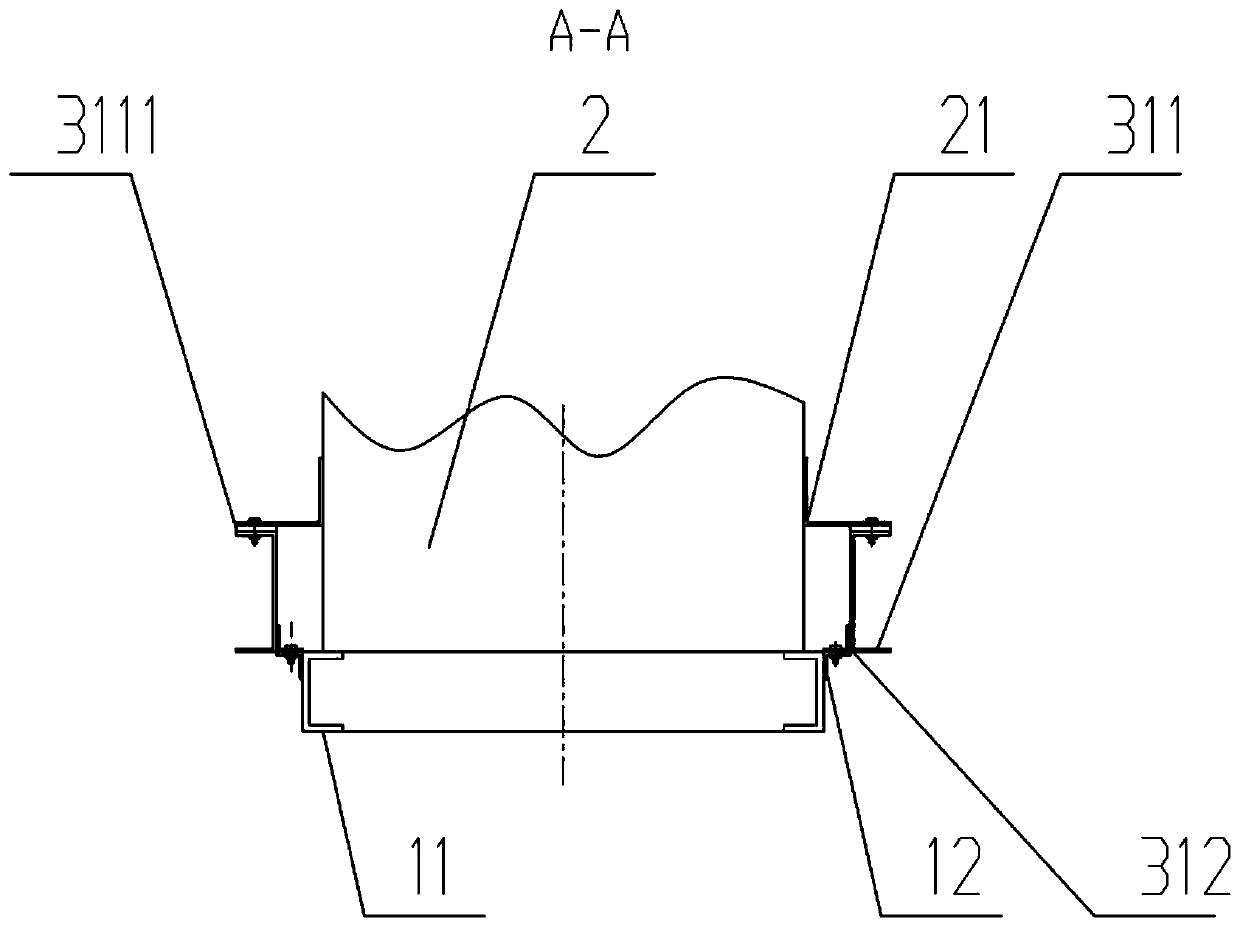

[0024] Such as Figure 1 to Figure 3 As shown, a special vehicle subframe for electric power is arranged on the vehicle chassis 1, and is used to carry and install the ring network cabinet 2 or other large electric equipment. The subframe 31 includes a front longitudinal beam 311, a rear longitudinal beam 314, The front beam 316 and the rear beam 317, the front beam 316 is connected between the two front longitudinal beams 311 to form the front structure of the subframe, and the rear beam 317 is connected between the two rear longitudinal beams 314 to form the rear structure of the subframe , the front structure and the rear structure are connected together to form an integral structure; the front str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com