Medium-low viscosity glue preparation machine

A low-viscosity, glue technology, applied in mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve the problems of long vacuuming time for glue filling, affecting glue filling efficiency, glue pretreatment, etc. Glue efficiency, avoid crystallization, good defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

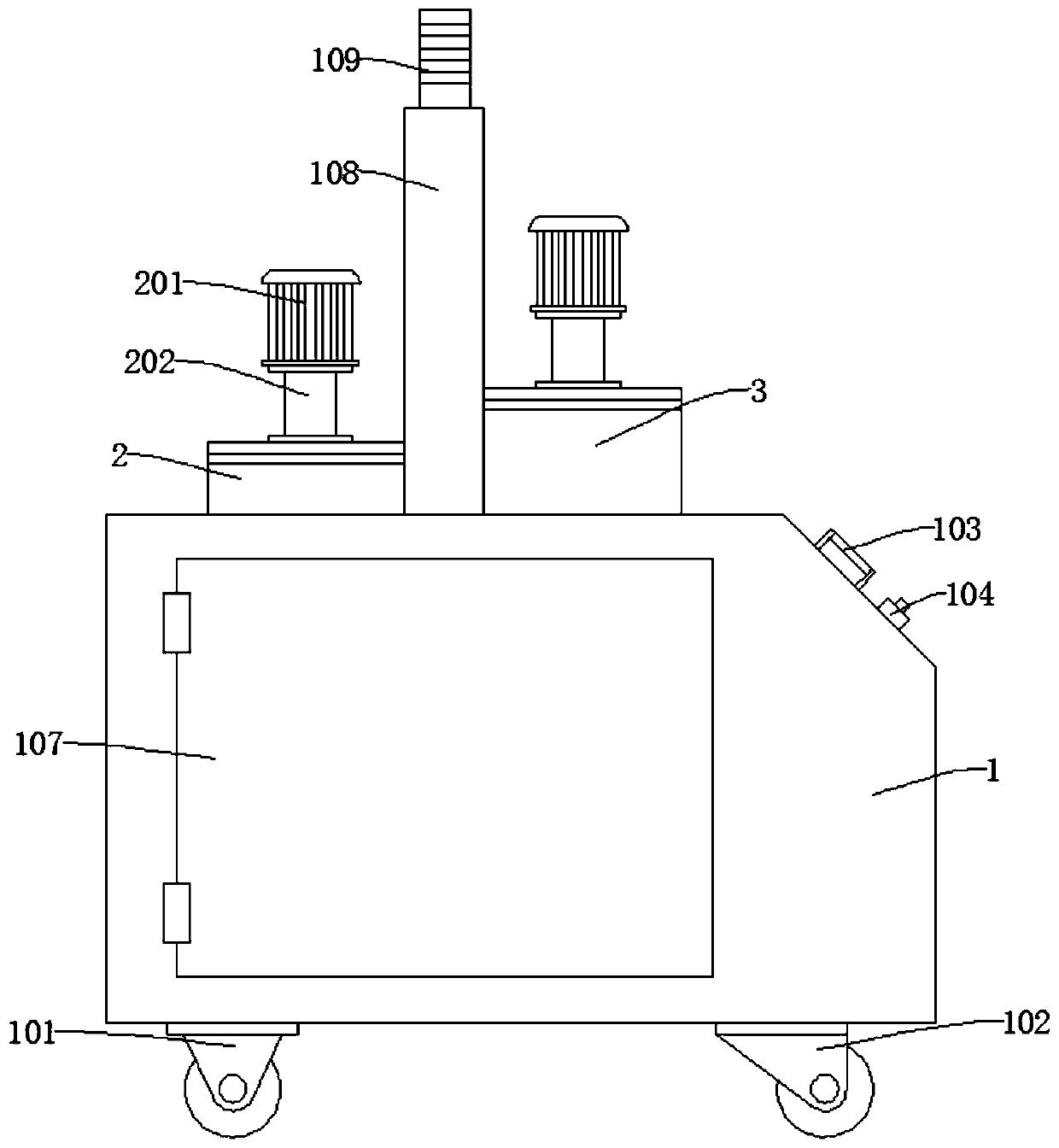

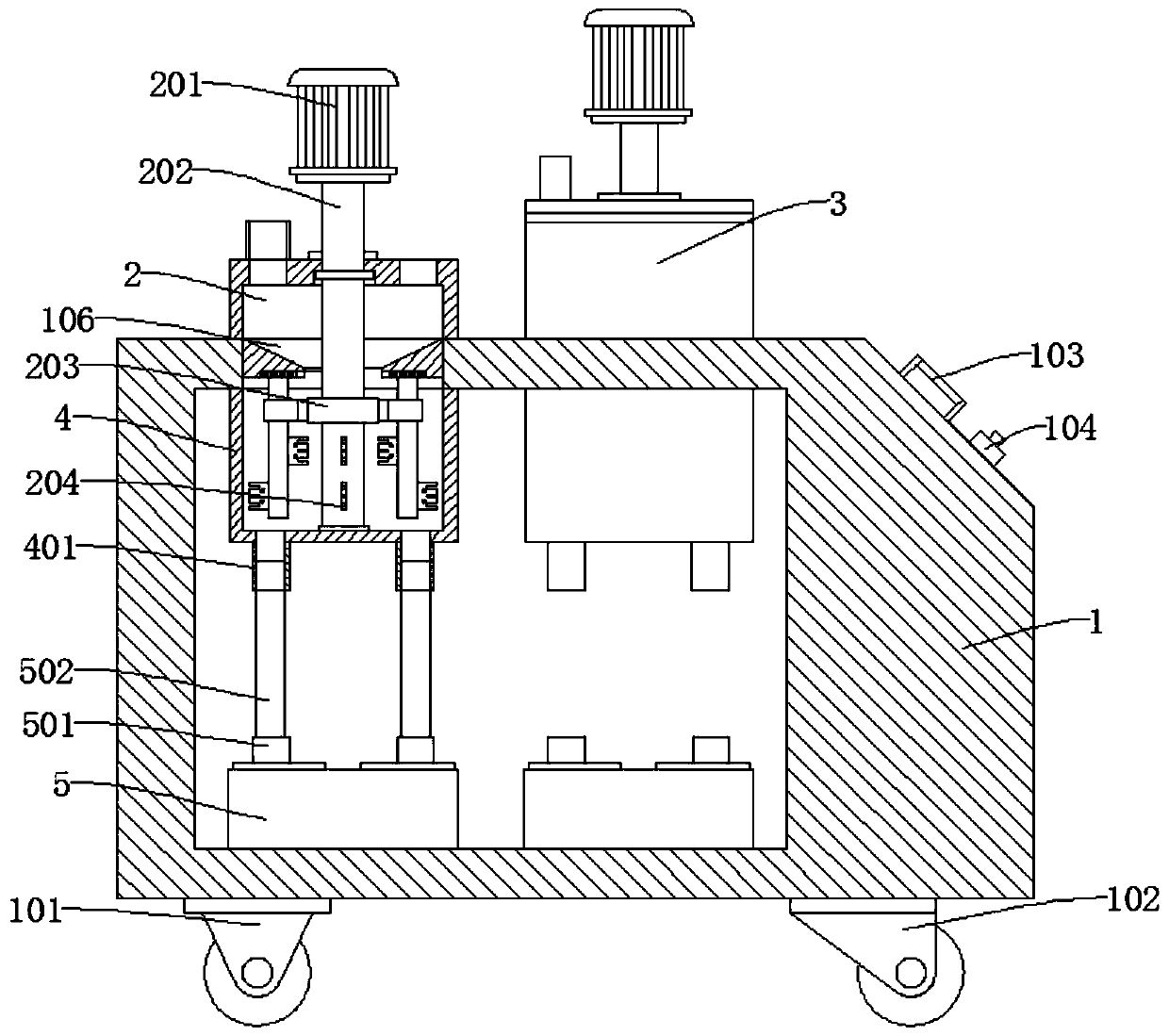

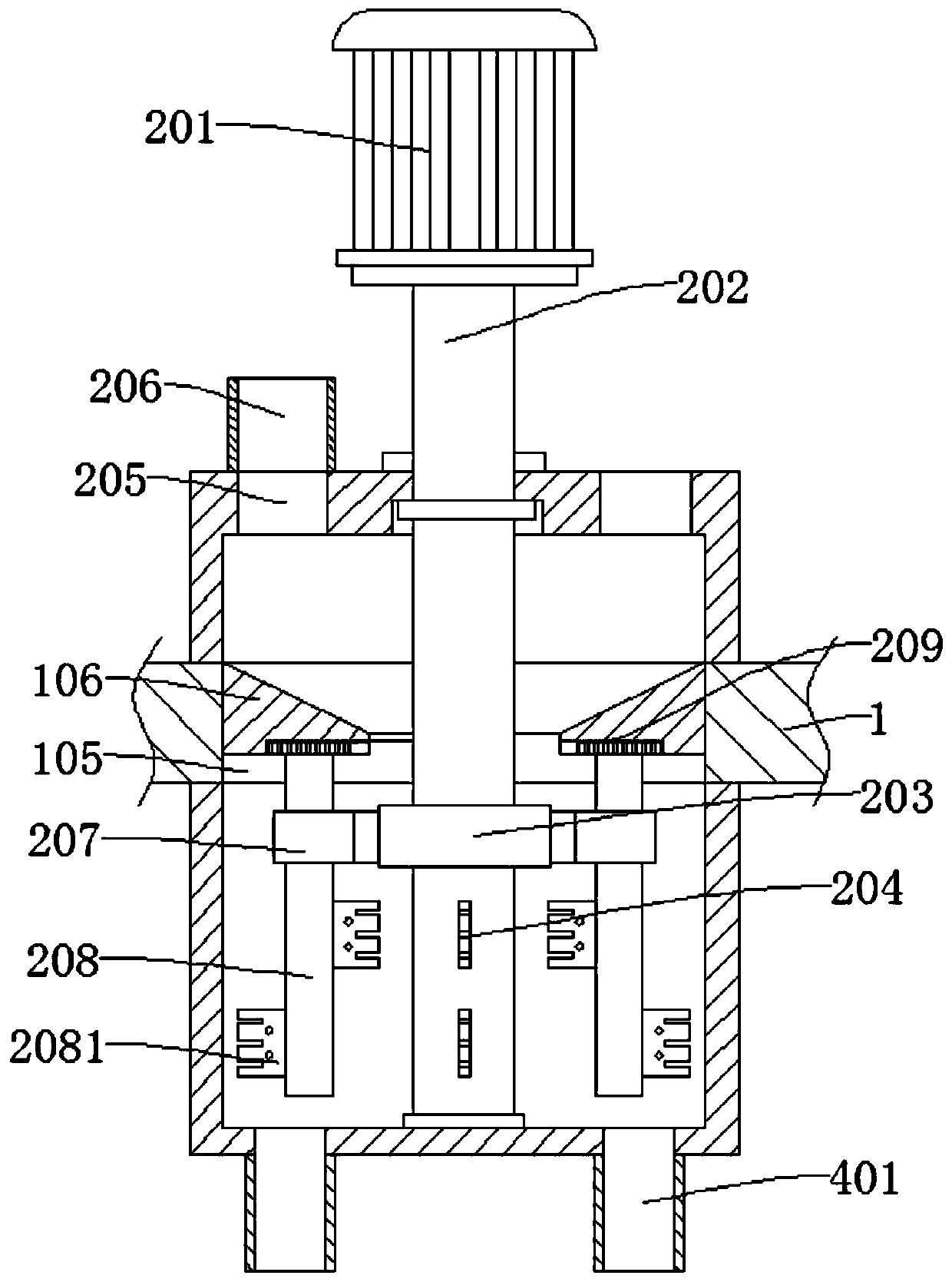

[0029] refer to Figure 1-6 , a kind of low-viscosity glue material preparation machine, comprises body 1, and the top outer wall of body 1 is provided with first feed tank 2 and second feed tank 3, on the first feed tank 2 and the second feed tank 3 A rotating shaft 202 is connected by rotation, and the rotating shaft 202 is connected to the output end of the stirring motor 201;

[0030] The body 1 is provided with a cavity, and the top inner wall of the cavity is provided with a discharge tank 4 that matches the first feed tank 2 and the second feed tank 3, and the body 1 is provided with a through hole 105 that communicates with each other. , one end of the rotating shaft 202 away from the stirring motor 201 is connected to the bottom inner wall of the discharge tank 4;

[0031] The outer wall of the rotating shaft 202 is connected with the first stirring plate 204, the outer wall of the rotating shaft 202 is also connected with the connecting block 203, the outer wall of ...

Embodiment 2

[0042] refer to Figure 1-6 , a kind of low-viscosity glue material preparation machine, comprises body 1, and the top outer wall of body 1 is provided with first feed tank 2 and second feed tank 3, on the first feed tank 2 and the second feed tank 3 A rotating shaft 202 is connected by rotation, and the rotating shaft 202 is connected to the output end of the stirring motor 201;

[0043] The body 1 is provided with a cavity, and the top inner wall of the cavity is provided with a discharge tank 4 that matches the first feed tank 2 and the second feed tank 3, and the body 1 is provided with a through hole 105 that communicates with each other. , one end of the rotating shaft 202 away from the stirring motor 201 is connected to the bottom inner wall of the discharge tank 4;

[0044] The outer wall of the rotating shaft 202 is connected with the first stirring plate 204, the outer wall of the rotating shaft 202 is also connected with the connecting block 203, the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com