Antiresonant hollow core preforms and optical fibres and methods of fabrication

A technology of hollow-core fiber and anti-resonance, which is applied in the direction of polarization fiber, cladding fiber, manufacturing tools, etc., and can solve the problems that optical performance cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Aspects and features of certain examples and embodiments are discussed / described herein. Some aspects and features of certain examples and embodiments may be implemented conventionally and are not discussed / described in detail for the sake of brevity. Accordingly, it will be appreciated that aspects and features of the devices and methods discussed herein that are not described in detail can be implemented according to any conventional techniques for implementing such aspects and features.

[0037] Embodiments of the present disclosure relate to preforms for fabricating anti-resonant hollow core optical fibers configured to improve the relative positions of various components contained in an optical fiber drawn from the preform.

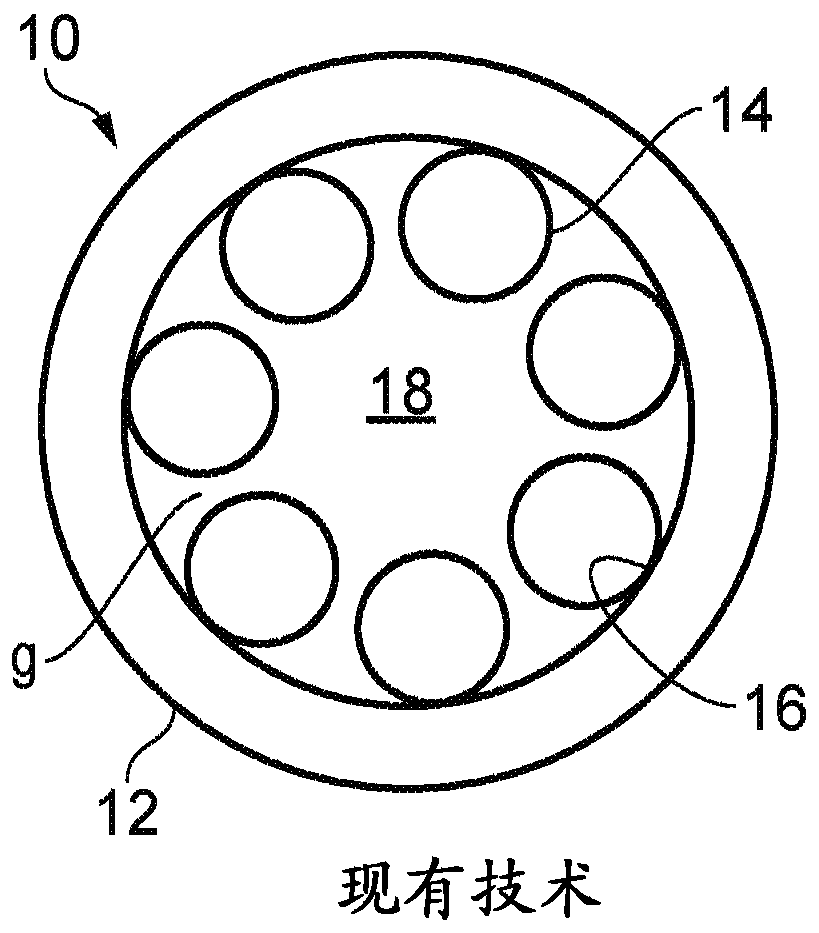

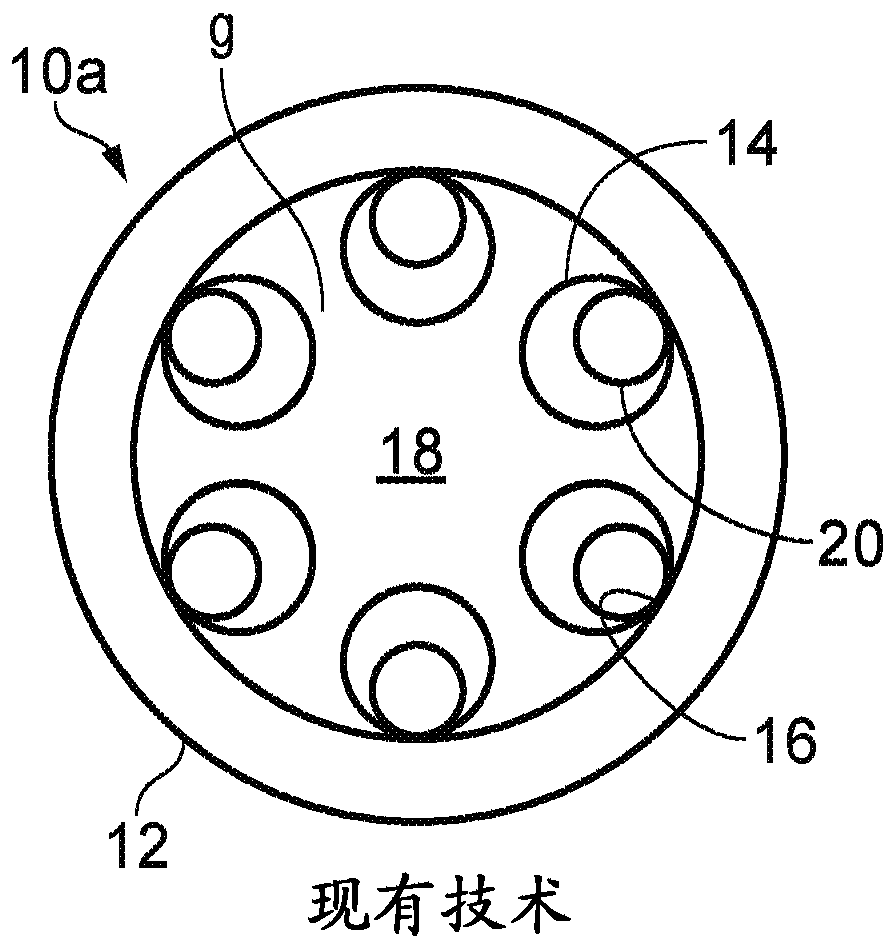

[0038] figure 1 A schematic cross-sectional view of an idealized antiresonant hollow-core fiber with a precise, symmetrical structure is shown. The cross-sectional arrangement of the components is preserved along the length of the fiber 10 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com