Friction plate active return mechanism

A return mechanism and friction plate technology, which is applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problem that the friction plate cannot be actively returned, so as to improve fuel utilization, reduce the incidence of jitter, reduce Effects of Unintended Wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with examples.

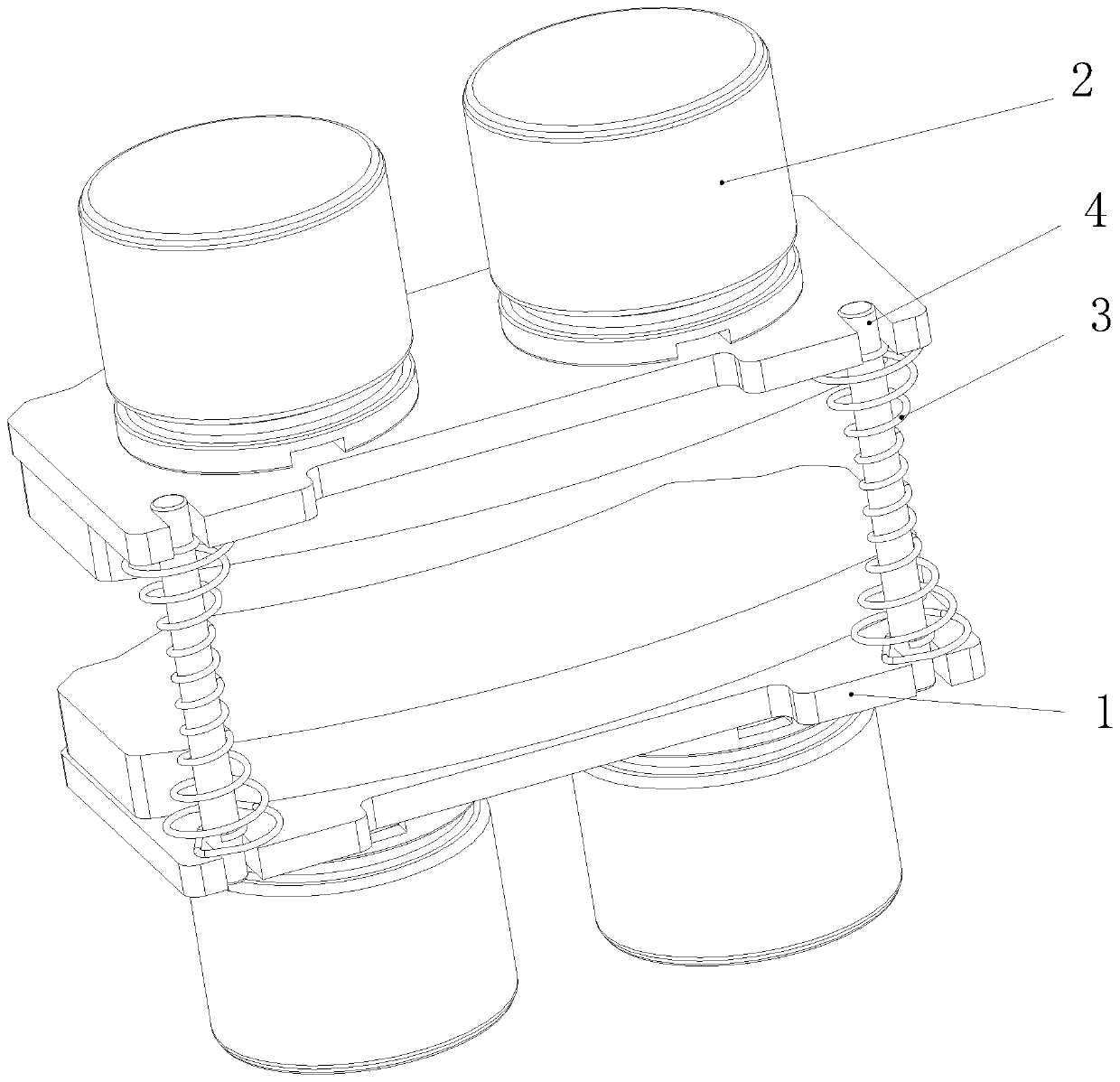

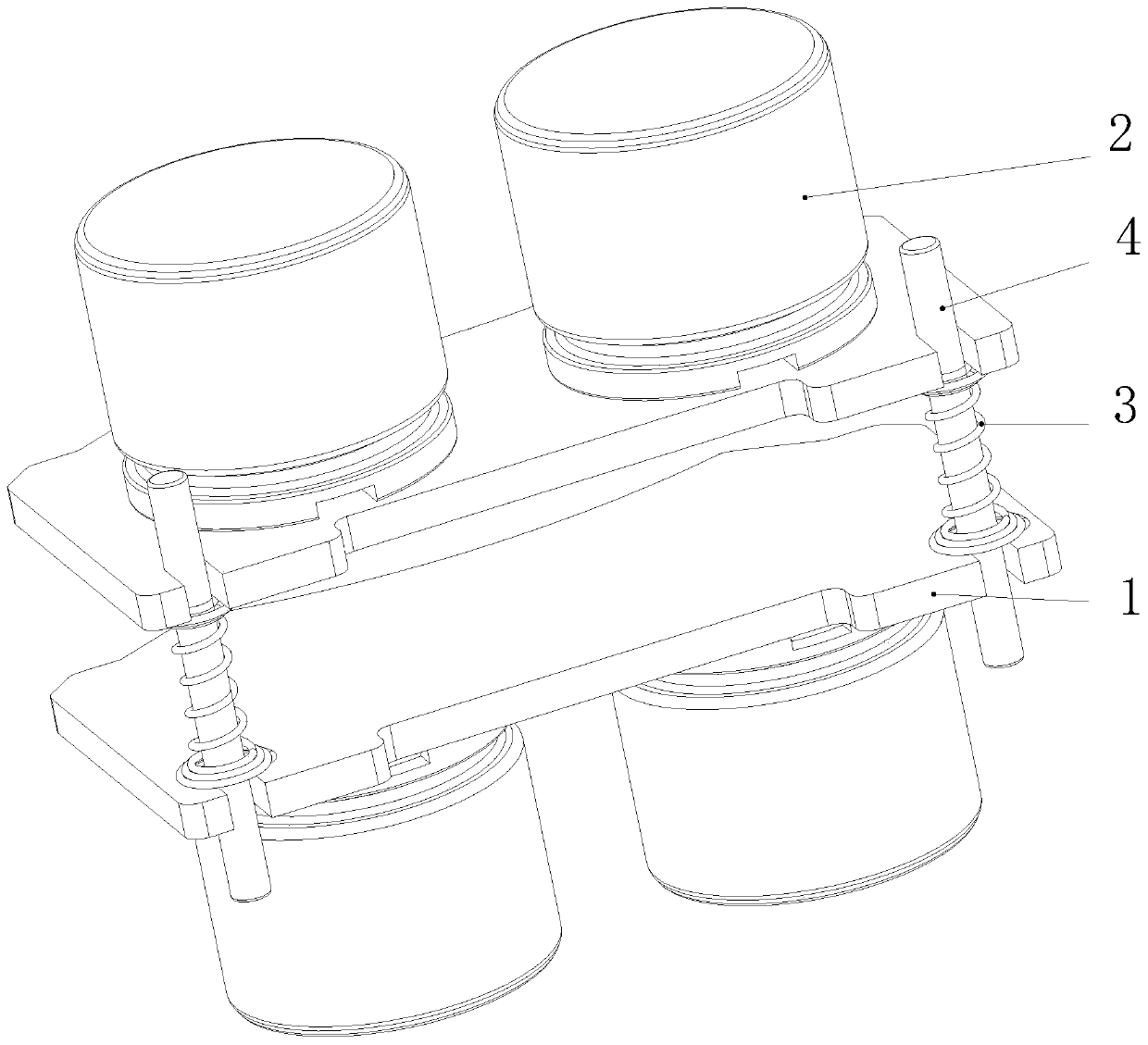

[0023] Such as figure 1 As shown, a friction plate active return mechanism includes a fixed caliper, and the friction plate 1 located on both sides of the brake disc is installed on the fixed caliper. The fixed caliper can be single cylinder, double cylinder or multiple cylinders. This embodiment is double cylinder.

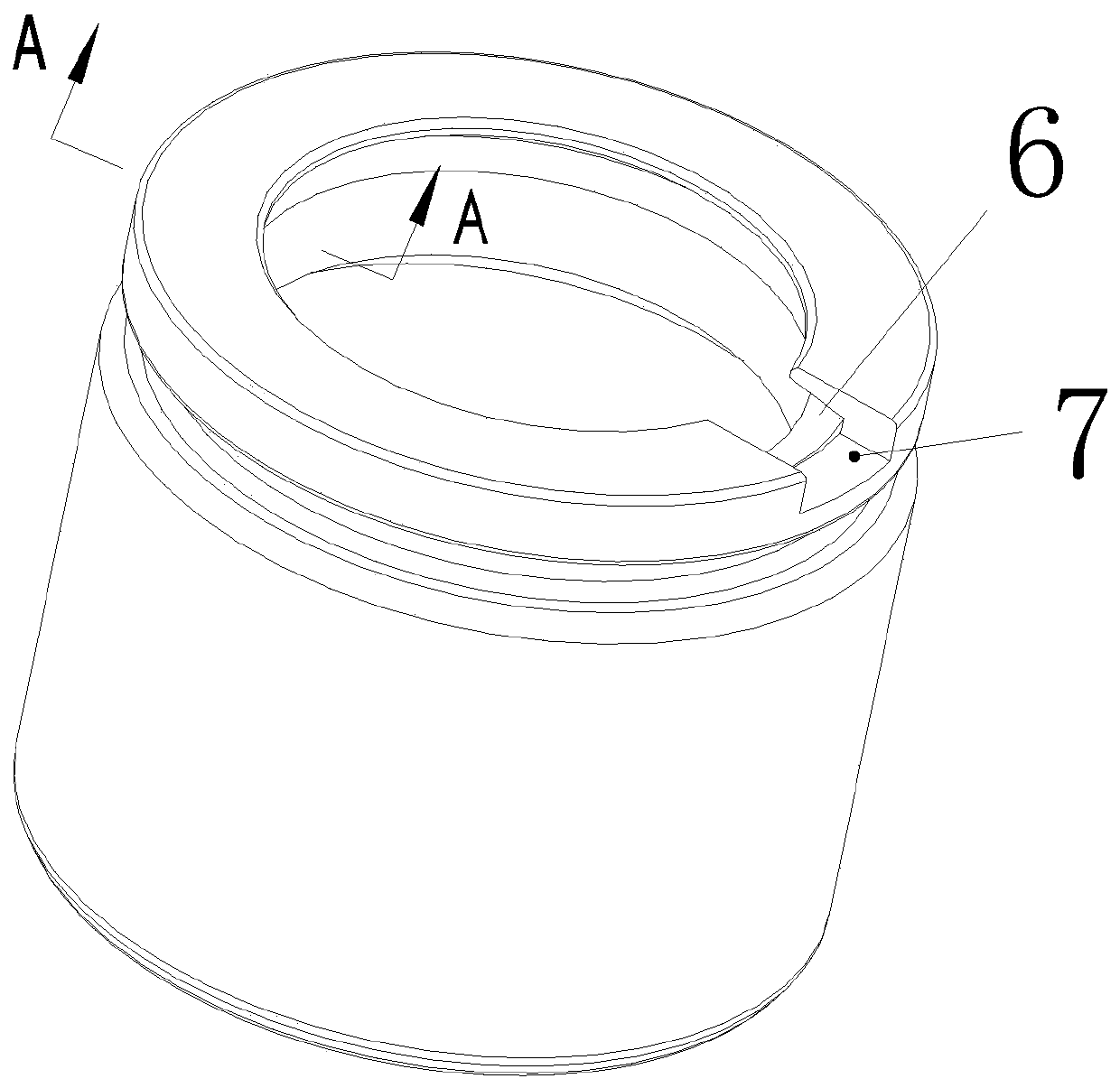

[0024] Such as figure 1 , 2 , 6, there are two return elastic parts between the two friction plates 1, and the two return elastic parts are symmetrically arranged at both ends of the upper part of the friction plate 1; the initial state of the two return elastic parts after installation is It is a compressed state with a certain initial elasticity.

[0025] Among them, the return elastic member preferably chooses a concave-shaped coil spring 3, and the concave-shaped coil spring 3 is a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com