An automatic arrangement device for garlic pre-production process

An automatic arrangement and pre-process technology, applied in metal processing and other directions, can solve the problems of uneven slices, inability to locate garlic cloves, and high degree of automation, and achieve the effects of energy saving, simple and reliable structure, and good linkage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

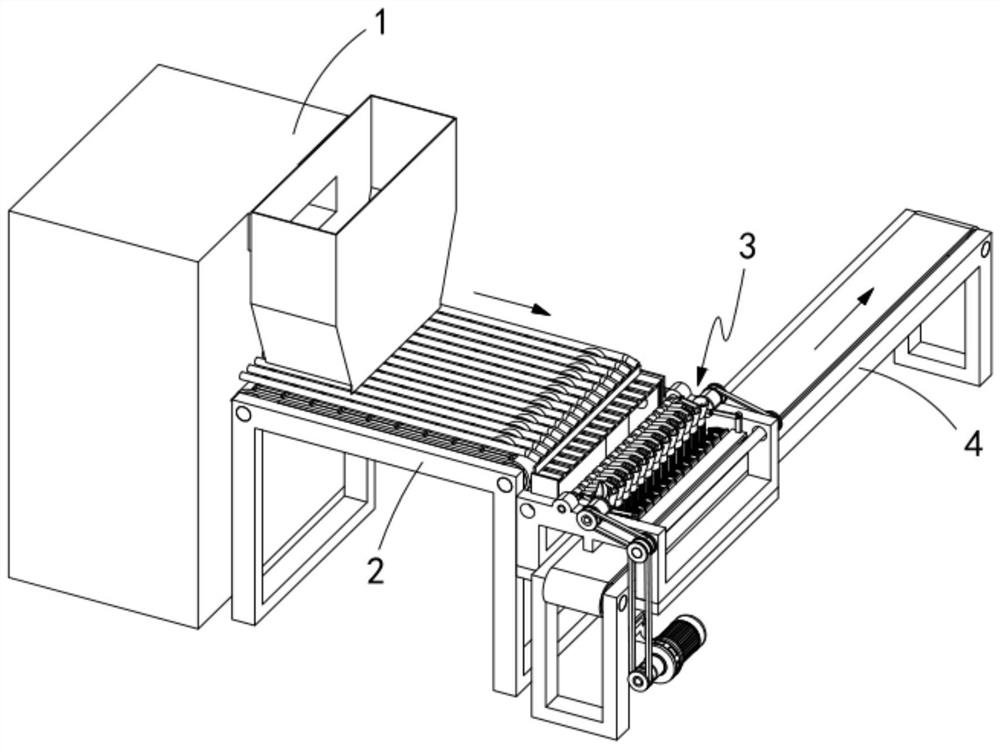

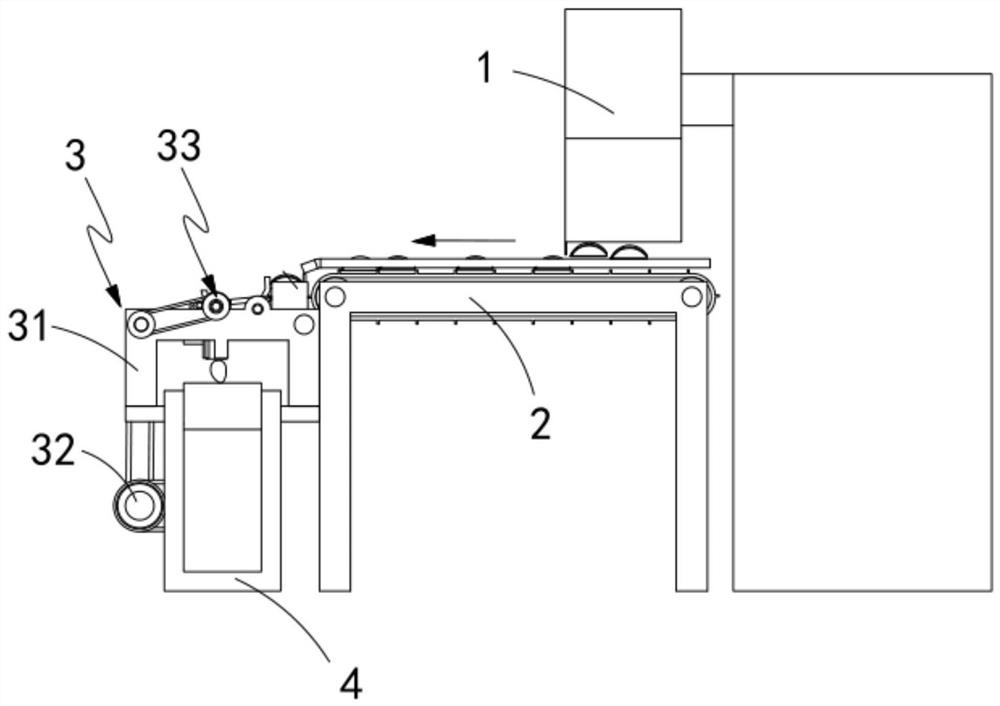

[0047] Such as figure 1 , figure 2 As shown, the automatic arrangement device for the pre-production process of garlic includes a garlic clove feeder 1, a feeding conveying device 2 and a discharging conveying device 4, the garlic clove feeding machine 1 is arranged at the head end of the feeding conveying device 2, so The discharge conveying device 4 is laterally arranged at the tail end of the feeding conveying device 2, and also includes:

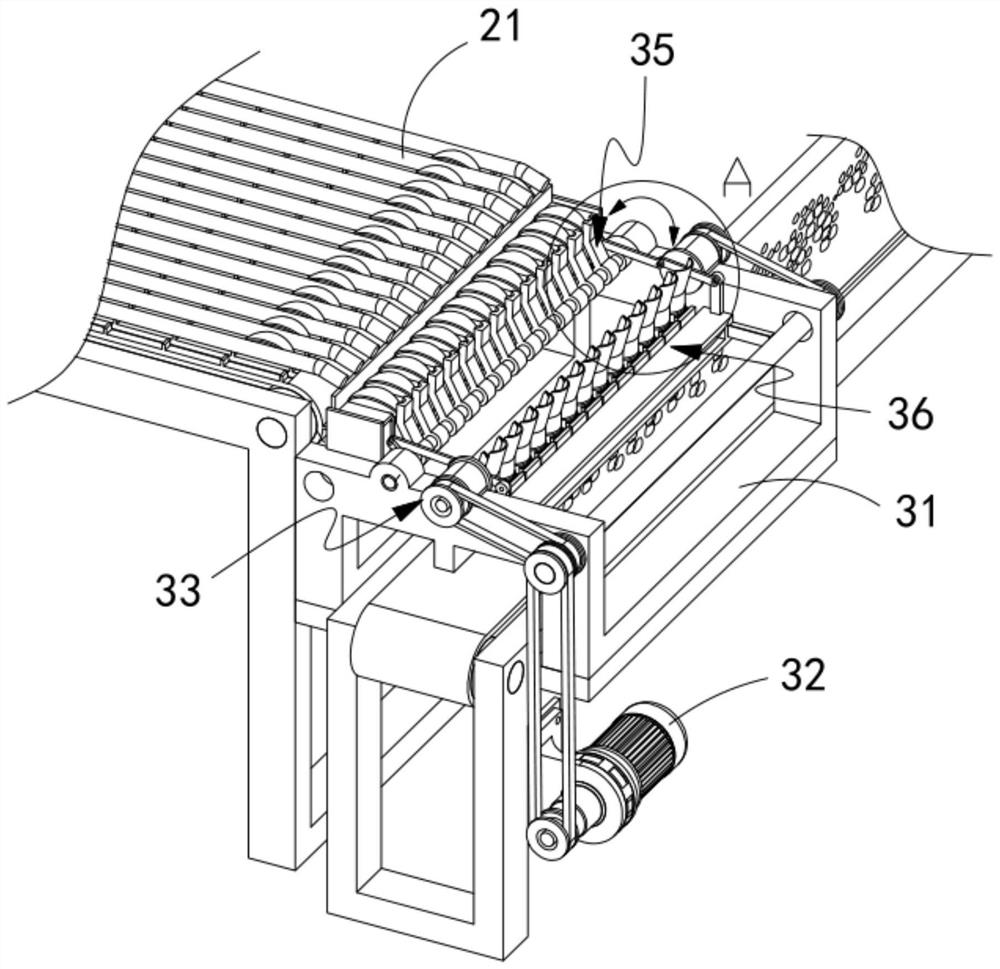

[0048] The slicing device 3, the slicing device 3 includes a fixed frame 31, a drive motor 32, a transmission assembly 33, a transfer assembly 35 and a slicing assembly 36, the fixed frame 31 is erected on the head of the transmission direction of the discharge transmission device 4, and the The driving motor 32 is fixedly arranged under the head of the transmission direction of the discharge transmission device 4, the transmission assembly 33 is arranged at both ends of the fixed frame 31 in the length direction, and the driving motor...

Embodiment 2

[0071] Such as Figure 10 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0072] Such as Figure 10 As shown, the end of the transfer unit 352 away from the rotating shaft a351 is provided with a notch 3511, and a number of garlic needles 3512 are arranged in the notch 3511, and the transfer unit 352 rotates with the transfer assembly 35 to the The receiving table 341 receives garlic cloves.

[0073] It should be noted that in the present invention, the notch 3511 of the transfer unit 352 is set according to the requirements of the tip of the garlic clove, which can accommodate the entry of the pointed end of the garlic clove, but the flat end of the garlic clove cannot enter the notch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com