A reconstruction device and reconstruction method for accurate reconstruction of parallel contours

A contour and precise technology, applied in measurement devices, instruments, etc., can solve the problems of high-density sampling and no data processing errors, data processing errors, influence of measurement results, etc., to achieve rich data, accurate reconstruction, and operation. The effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

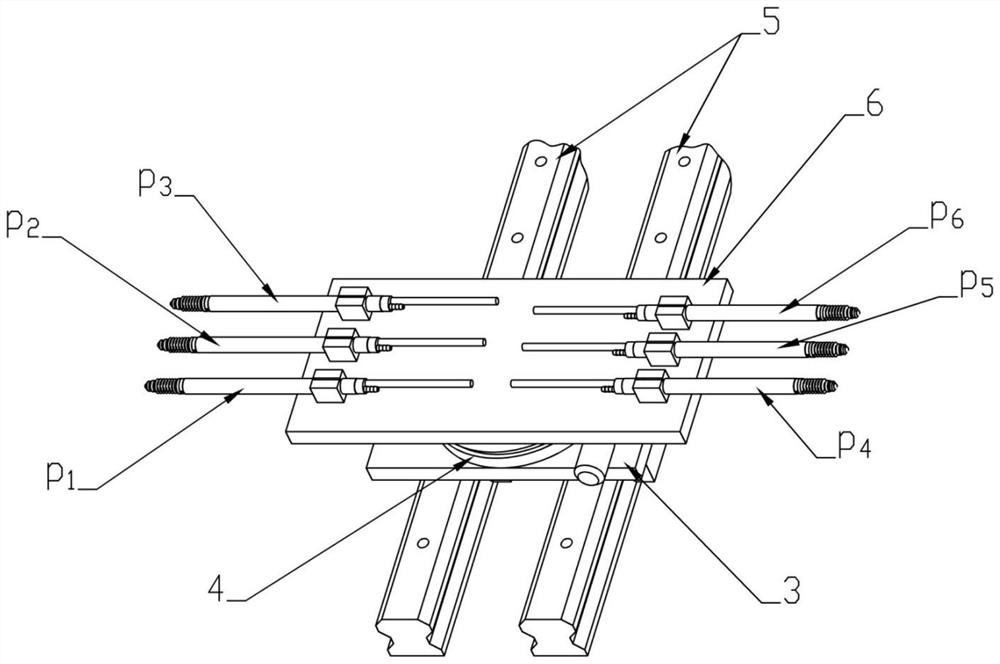

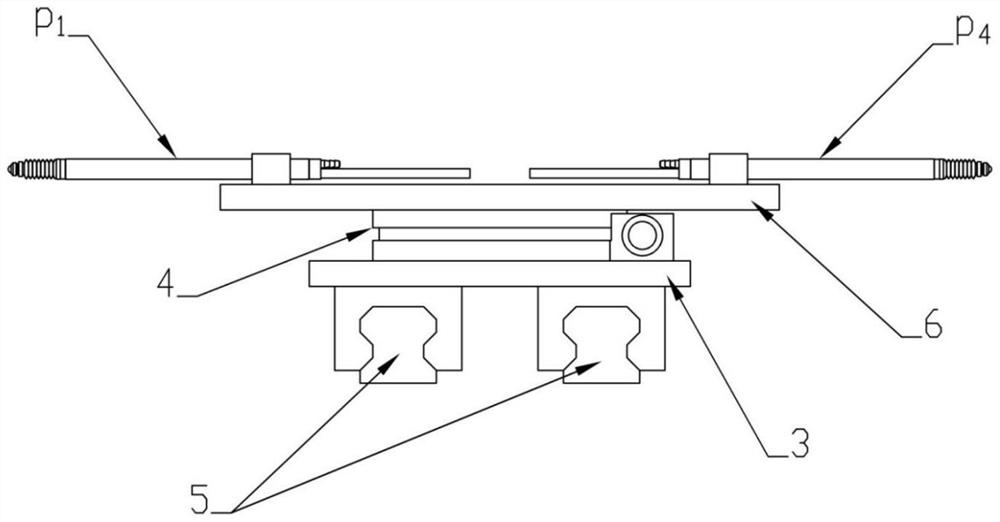

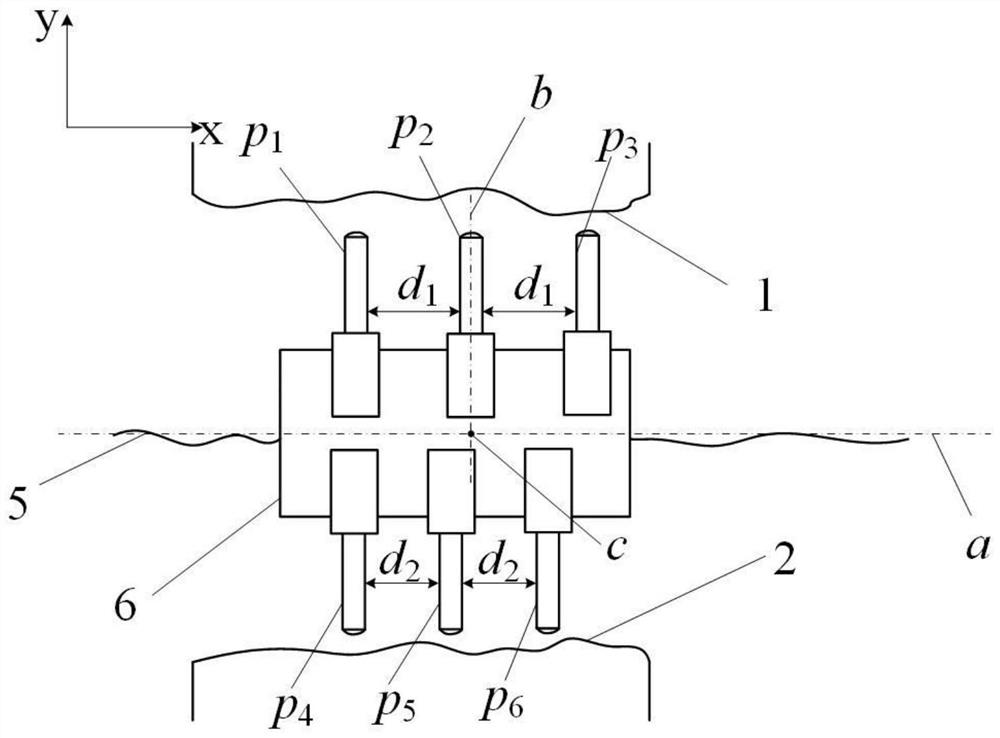

[0038] A reconstruction device and a reconstruction method for precise parallel contour reconstruction of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0039] A reconstruction device and reconstruction method for accurate reconstruction of parallel contours of the present invention removes the influence of the straightness error and yaw error of the measurement reference on the measurement results through an appropriate data processing method, and performs the measurement by rotating the measurement device by 180° Secondary scanning measurement eliminates the influence of zero error of sensor installation on the measurement results, and through the arrangement of sensors in the system and the design of data processing algorithms, no calculation error reconstruction can be realized when the step distance of the device is smaller than the distance between sensors . Accurate reconstruction of parallel pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com