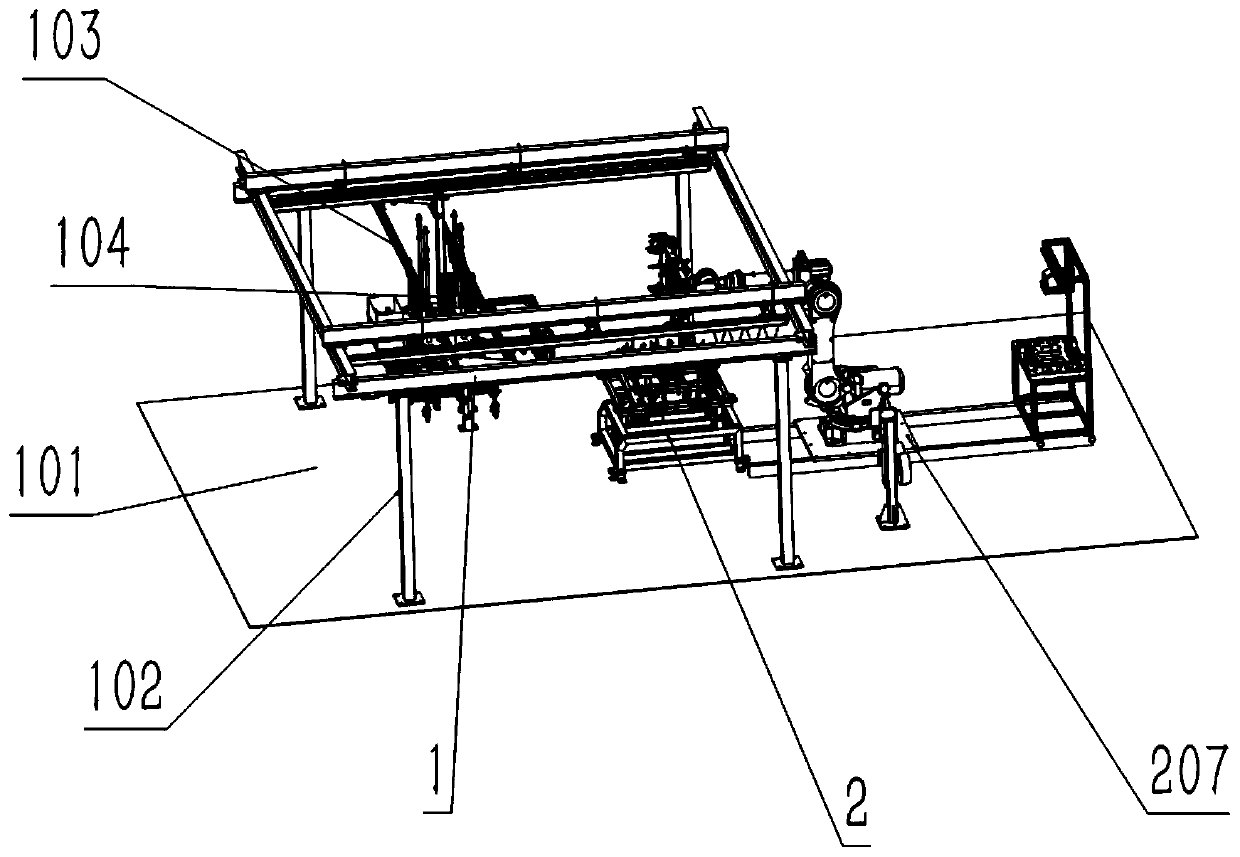

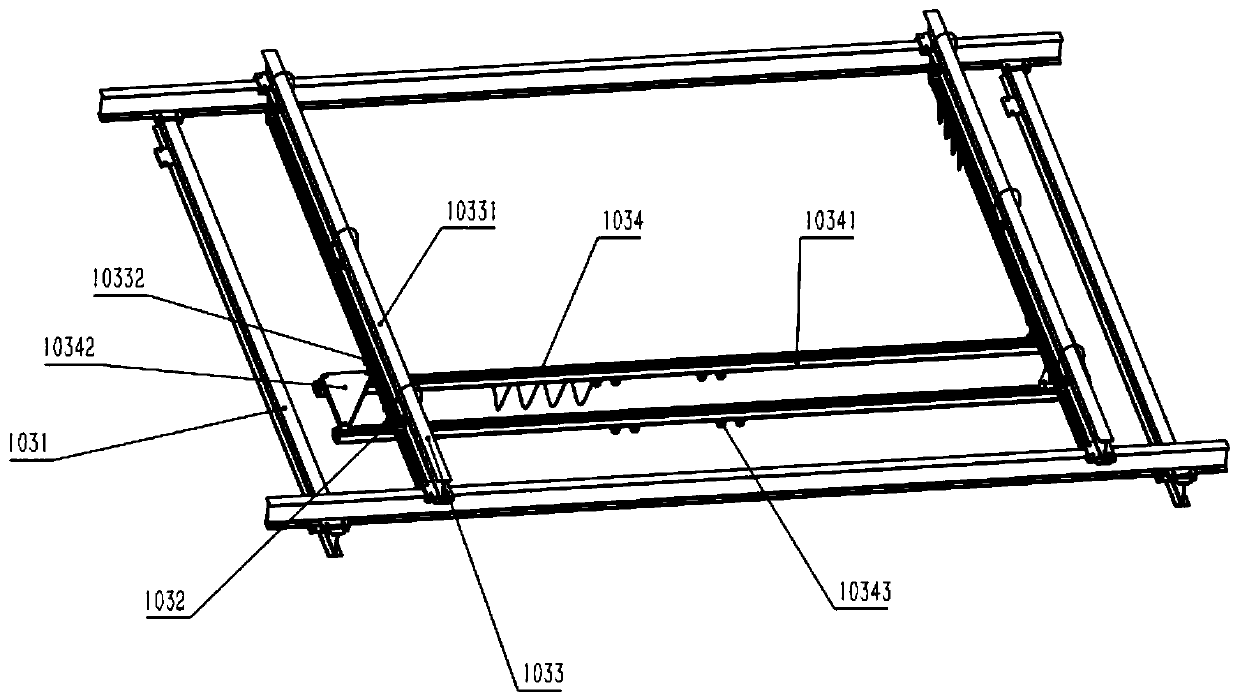

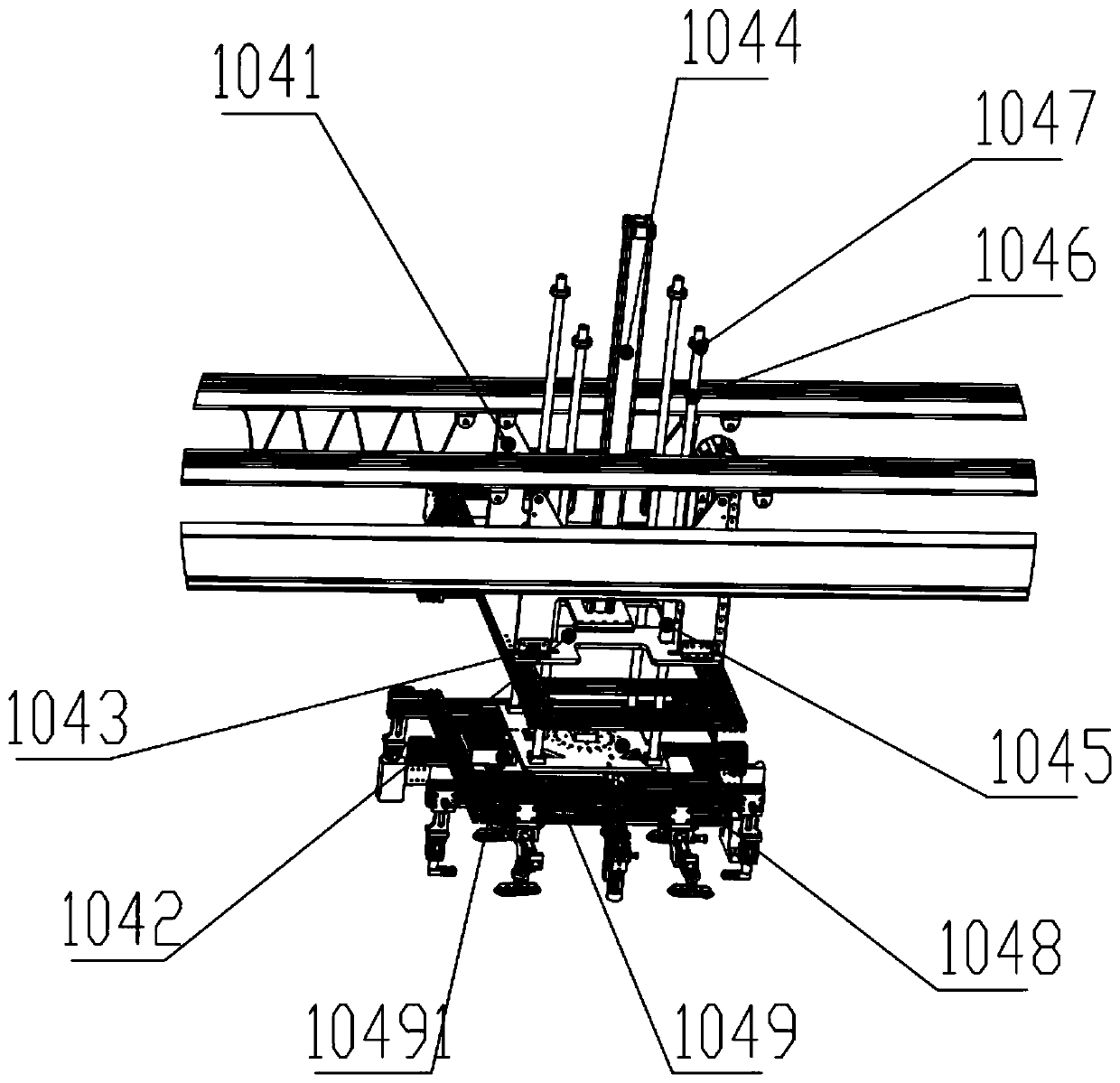

Welding production system for skylight framework of electric automobile and method thereof

A production system and electric vehicle technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increased working time for skylight installation, non-universal skylight frame, waste of installation time, etc., to shorten the handling of glass Time saving, production cost saving, installation efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] After the applicant's research and analysis, most of the prior art sunroof frameworks are welded, and the welding and installation glass are mostly installed separately, and the process is separated, and because the models of the skylight frameworks are different, the sunroof frameworks of each model are different. It is not universal, so the traditional technology needs to replace different welding tooling for the sunroof frame of different models, and then the welding tooling works, so that different models of welding tooling are made for different models, and the production cost is huge, and In the prior art, the process of glass and frame is separated, and it is necessary to manually move the glass through a robot or operator, and enter a designated route to reach the frame of the skylight for operation. The installation time of the skylight is virtually increased, resulting in Waste of installation time. According to these problems, the applicant proposed a welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com