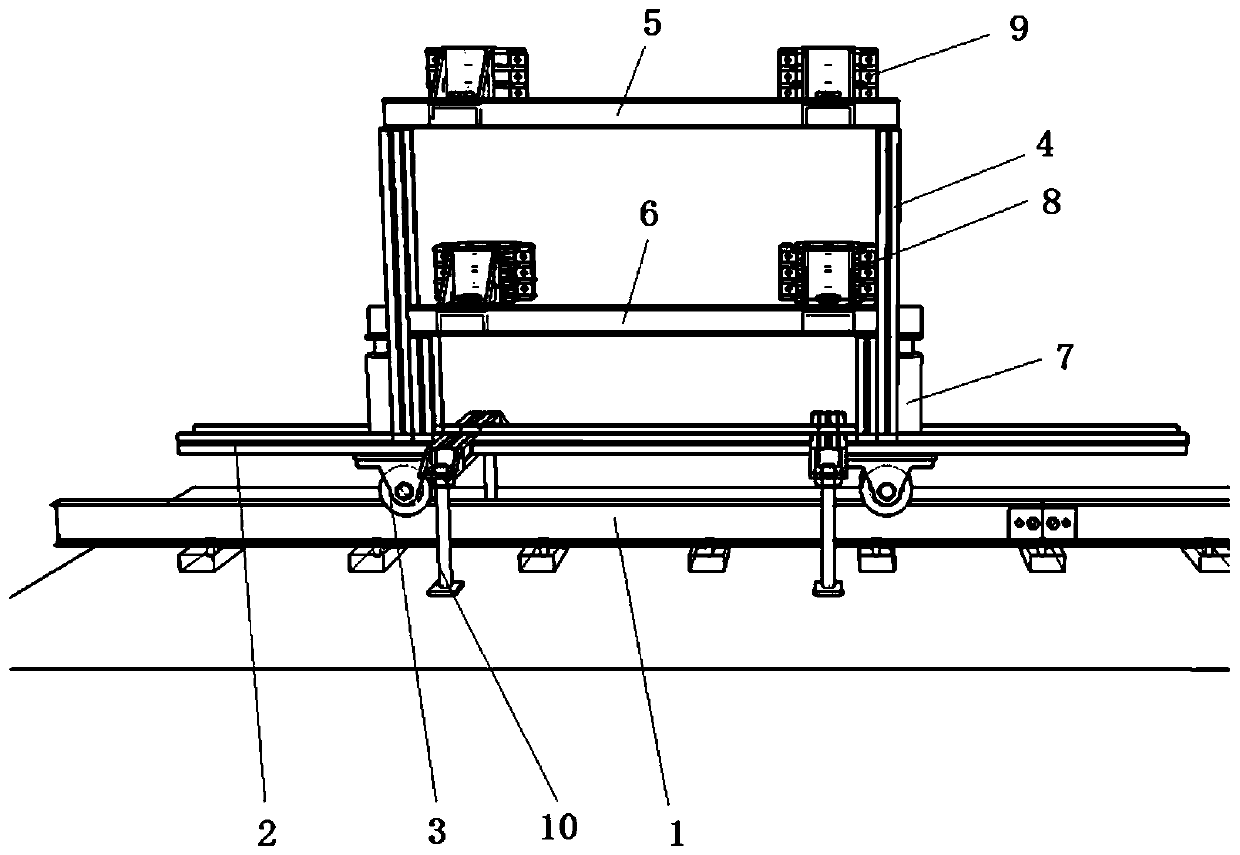

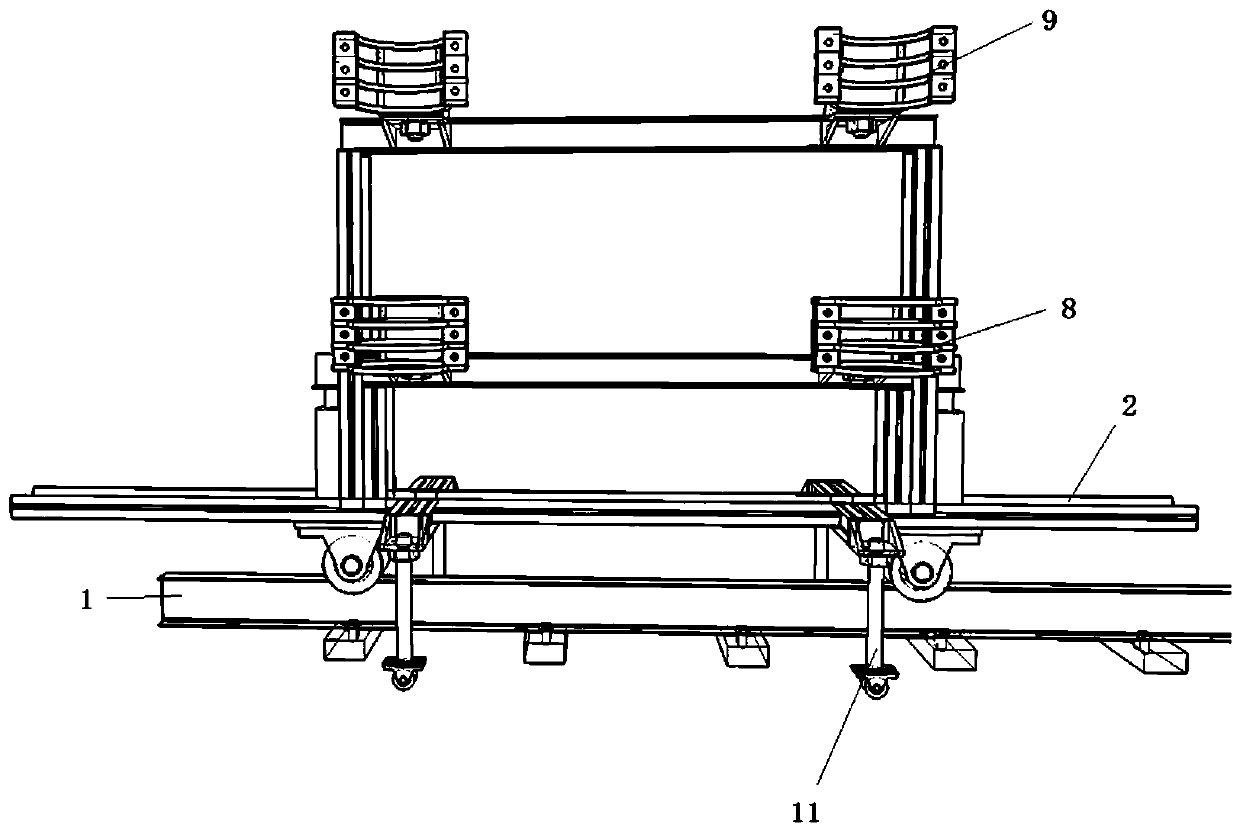

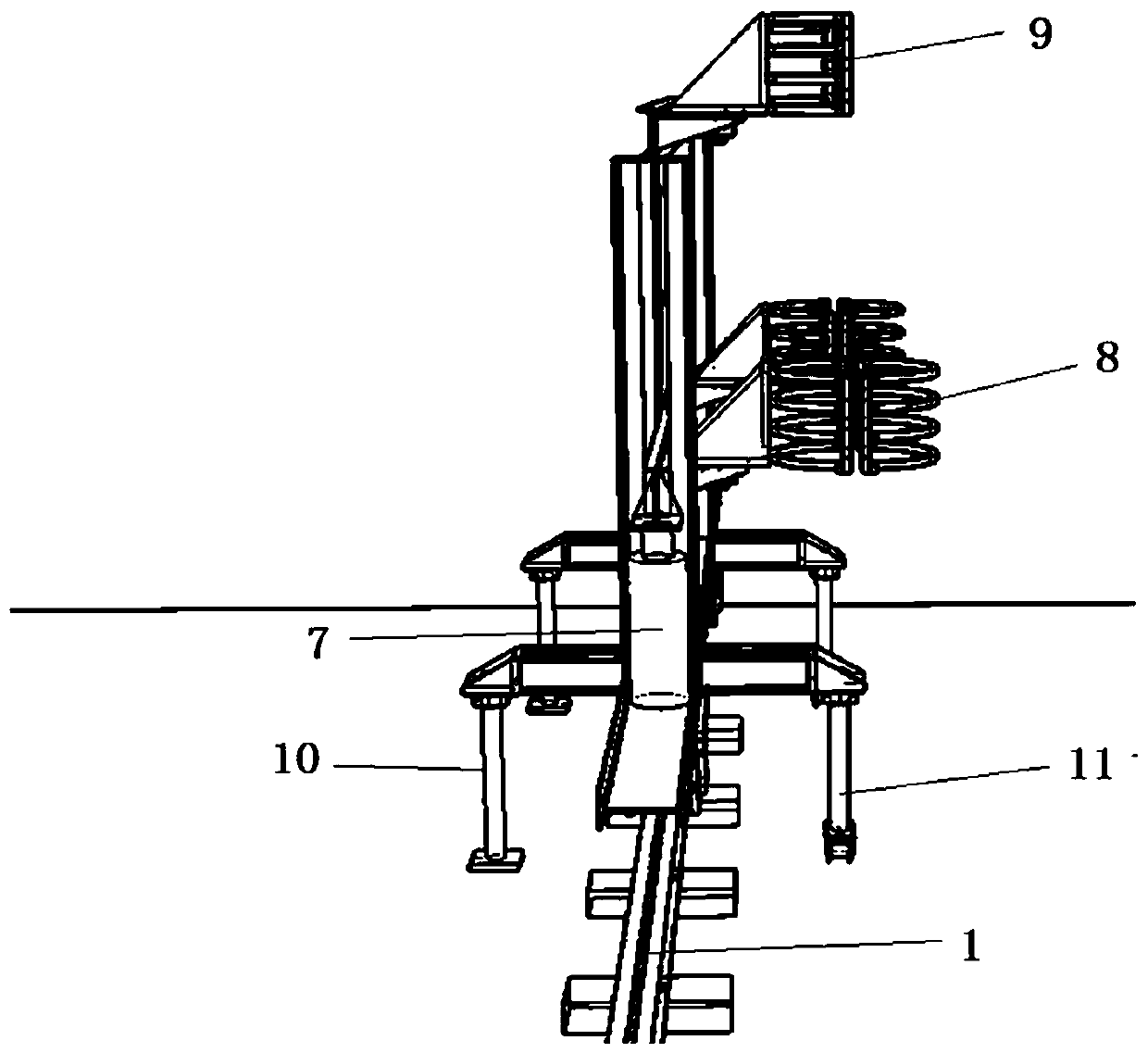

Rail type traction system for hoisting transportation

A traction system and track-type technology, which is applied in the direction of transportation and packaging, conveyors, lifting devices, etc., can solve the problems that cannot be hoisted in place at one time, the size of the equipment is large, the safety and economy cannot be effectively guaranteed, and the assembly is simple. , Strong applicability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0053] Example 1: The existing sewage plant tank capping project in a certain city needs to cover the main load-bearing steel structure truss above the 200m*200m*8.4m square pool, with a span of 35.6m and a weight of about 20t. Due to specific needs, the site cannot Assembled, a total of 72 pools, the maximum hoisting position is 80m away from the side of the pool body structure. Since the pool is located in the core area of the sewage plant operation, the shortest distance from other facilities of the sewage plant to the pool is only 23m, and there are only light-loaded roads for small vehicles in the surrounding area, so there are no conditions for parking and hoisting of ordinary large-scale lifting equipment. At the same time, under the normal operation of the sewage plant, that is, in the process of moving and hoisting the truss, it is necessary to effectively avoid all existing facilities to ensure the normal operation of the equipment.

[0054] Combined with the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com