Handle pop-up structure of change-over switch

A technology for changing switches and handles, which is applied in the direction of electric switches, electrical components, circuits, etc., which can solve the problems of easy loss, easy forgetting to put back, increase product dimensions, etc., and achieve the effect of avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

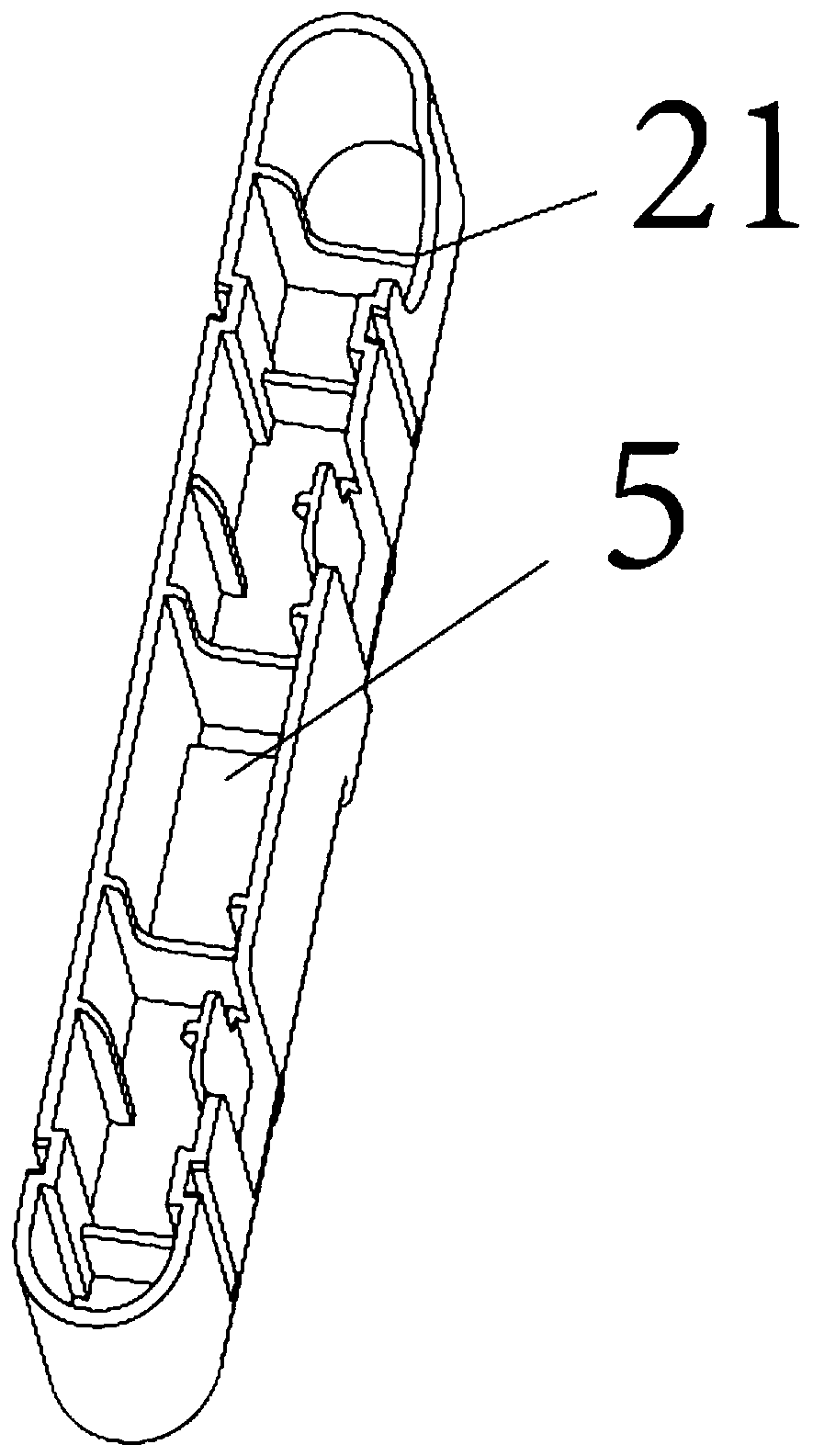

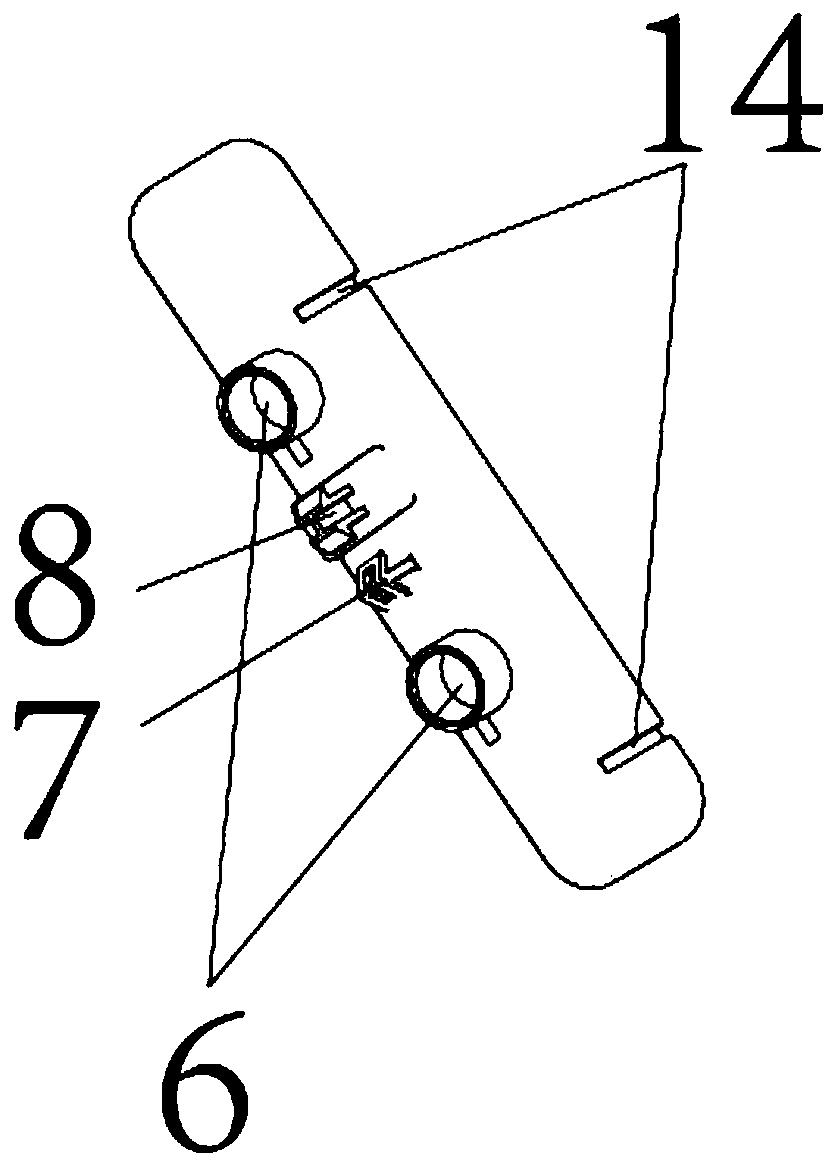

[0041] Such as Figure 1-19As shown, the handle pop-up structure of a transfer switch provided by this embodiment includes an upper case 1, a manual and automatic sliding cover, a handle box, a handle, a slide plate, a fixing member, and a spring; the upper surface of the upper case 1 is provided with a manual and automatic The slide cover sliding area 2, the manual automatic slide cover sliding area 2 is provided with a handle box warehouse 3 and a pair of guide grooves 4, the upper surface of the handle box forms a groove-shaped handle warehouse 5, and the bottom of the handle box is provided with at least A pair of spring bins 6, a first buckle 7 and a second buckle 8 are arranged between the spring bins 6, and the height of the end of the second buckle 8 from the bottom of the handle box is higher than that of the first buckle 7 The height of the bottom of the handle box; the bottom surface of the manual automatic sliding cover is provided with a pair of sliding columns 9;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com