Nanoimprint structure, its control method, nanoimprint device and patterning method

A technology of nano-imprinting and patterning, applied in the fields of nano-imprinting structures and nano-imprinting devices, can solve the problems of poor quality of soft templates, inability to guarantee uniformity, affecting display quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the nanoimprint technology in the related art, the hard template is made first, and then the hard template is re-engraved through the soft film plate, and the imprint pattern is formed on the soft template. Among them, because the hard template manufacturing process takes a long time, repeated Only one corresponding hard template is made for the graphics, and the graphics on the hard template are reproduced to different areas through multiple soft film plates, so as to realize the composition of different areas of the substrate.

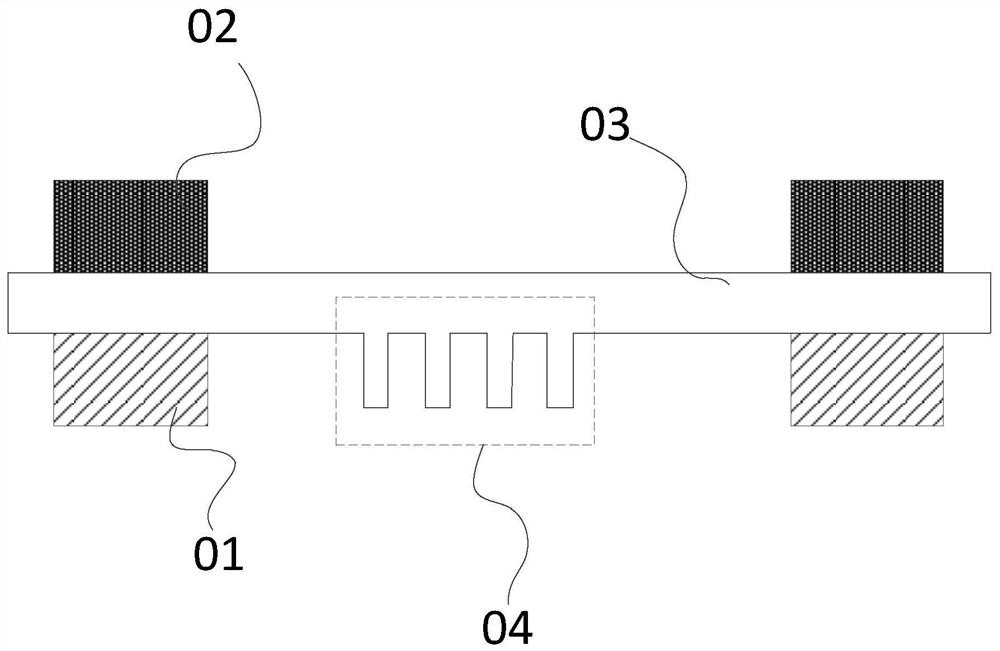

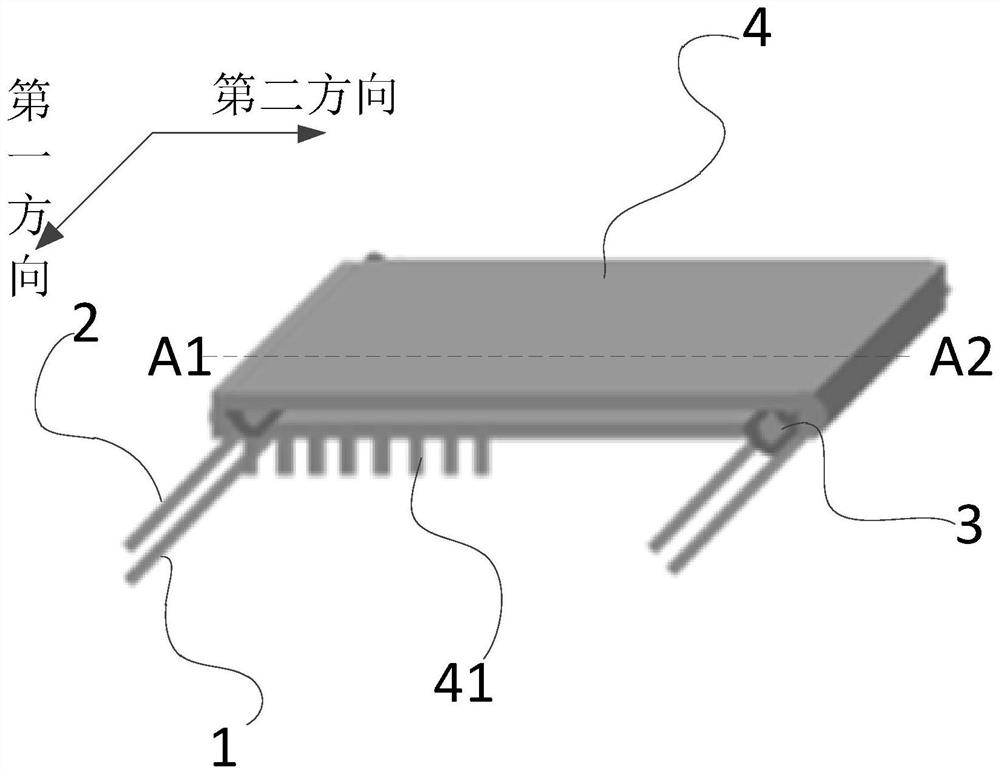

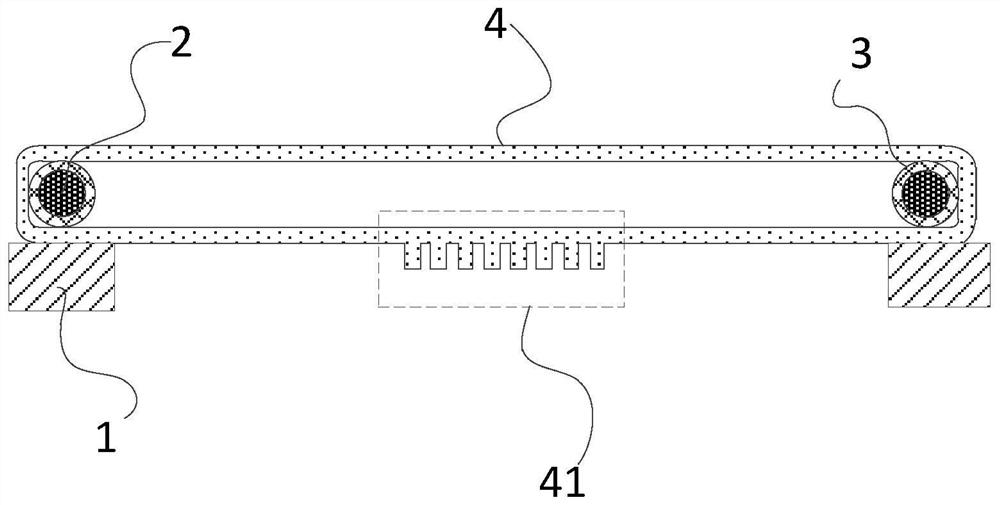

[0041] Among them, nanoimprint structures in related technologies, such as figure 1 As shown, it includes: fixed magnet 01, magnetic connecting rod 02, and the soft membrane plate 03 is fixed between the fixed magnet 01 and the magnetic connecting rod 02 through the suction force between the fixed magnet 01 and the magnetic connecting rod 02, each soft membrane The area where the embossed pattern 04 is located in the plate 03 is not the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com