Near-net forming lubricant and preparation method thereof

A near-net shape and lubricant technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of difficult cleaning, multiple processes, environmental pollution, etc., to improve storage stability, reduce environmental pollution, and good surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

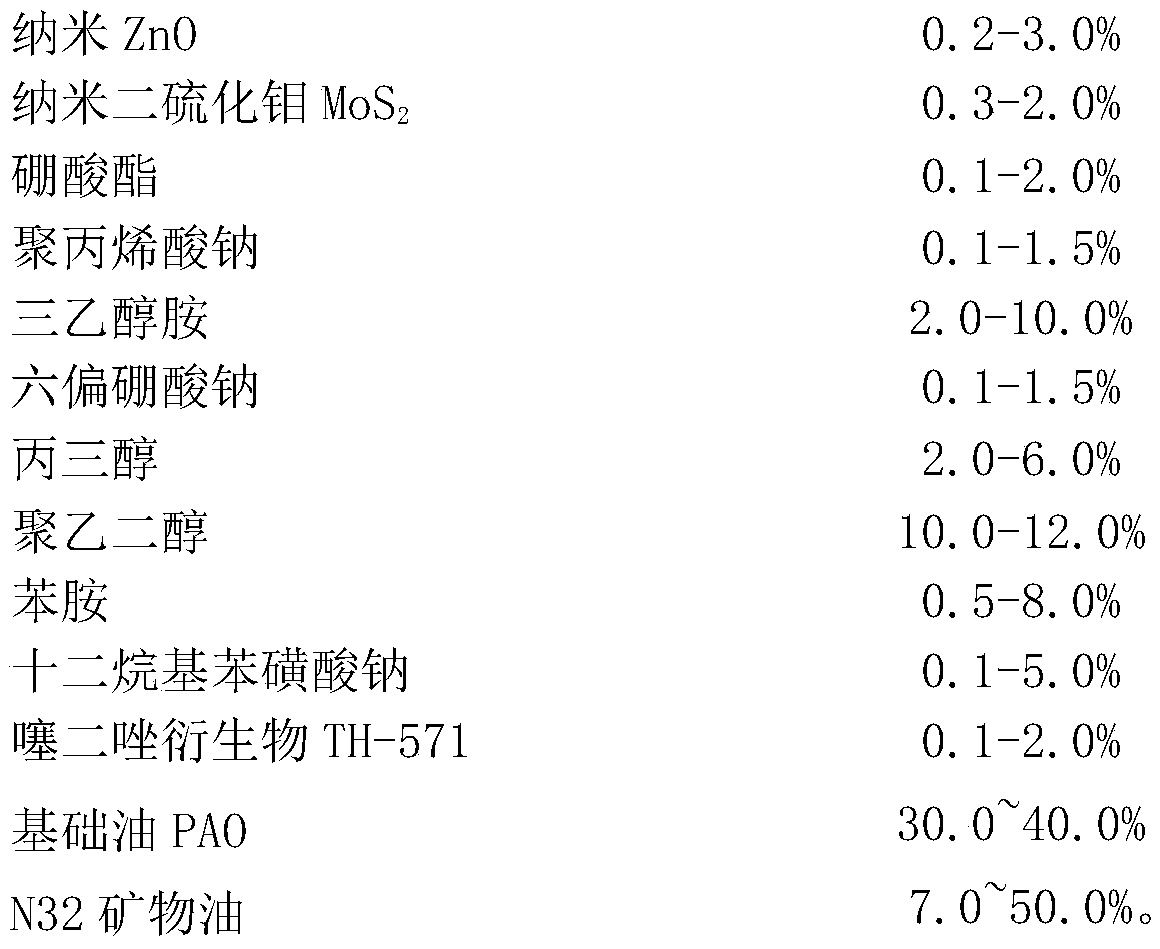

[0019] Embodiment 1 formula sees the following table:

[0020] serial number component name Weight percent (100%) 1 Nano ZnO (20-50nm) 0.2 2 Nano Molybdenum Disulfide MoS 2 (20-50nm)

[0021] According to the weight formula of each component in the above table, add 0.1g borate ester, 0.1g sodium dodecylbenzenesulfonate and 0.1g thiadiazole derivative TH-571 to base oil 30.0g PAO and 50.0g N32 mineral Oil, put it into a reaction kettle with a rotation speed of 2500-4500 rpm for heating and stirring, when the temperature reaches 60-80°C, add 0.2g nano-ZnO and 0.3g nano-MoS 2 , the stirring time is 45-60 minutes, then add 0.1g sodium polyacrylate, 2.0g triethanolamine, 0.1g sodium hexametaborate, 2.0g glycerol, 10.0g polyethylene glycol and 5.0g aniline in sequence, and keep the reaction kettle warm At 50-70°C, set the speed at 1500-300 rpm, and continue to stir for 25-40 minutes, then stop heating and continue to stir to room temperature, to obtain a ...

Embodiment 2

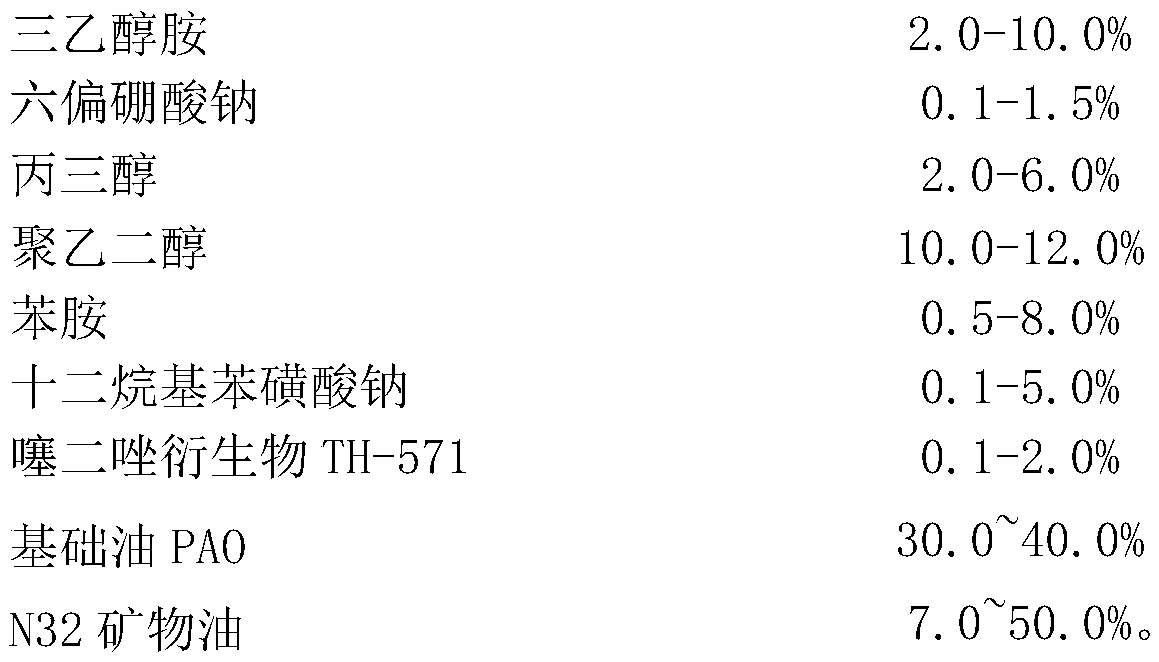

[0023] Embodiment 2 formula sees the following table:

[0024]

[0025]

[0026] According to the weight formula of each component in the above table, add 2.0g borate ester, 5.0g sodium dodecylbenzenesulfonate and 2.0g thiadiazole derivative TH-571 to base oil 40.0g PAO and 7.0g N32 mineral Oil, put it into a reaction kettle with a rotation speed of 2500-4500 rpm for heating and stirring, when the temperature reaches 60-80°C, add 3.0g nano-ZnO and 2.0g nano-MoS 2 , the stirring time is 45-60 minutes, then add 1.5g sodium polyacrylate, 10.0g triethanolamine, 1.5g sodium hexametaborate, 6.0g glycerol, 12.0g polyethylene glycol and 8.0g aniline in sequence, and keep the reaction kettle warm At 50-70°C, set the speed at 1500-300 rpm, and continue to stir for 25-40 minutes, then stop heating and continue stirring to room temperature, to obtain a dark brown oil body, which is made into the required gear and other complex parts for near-net shape lubrication agent, the formula...

Embodiment 3

[0028] Embodiment 3 formula sees the following table:

[0029] serial number component name Weight percent (100%) 1 Nano ZnO (20-50nm) 0.8 2 Nano Molybdenum Disulfide MoS 2 (20-50nm)

1.0 3 Borate 0.3 4 Sodium polyacrylate 0.4 5 Triethanolamine 2.0 6 Sodium hexametaborate 0.4 7 Glycerol 4.0 8 polyethylene glycol 11.0 9 aniline 0.5 10 Sodium dodecyl benzene sulfonate 0.5 11 Thiadiazole derivative TH-571 0.5 12 base oilPAO 35 13 N32 mineral oil 44

[0030] According to the weight formula of each component in the above table, add 0.3g borate ester, 0.5g sodium dodecylbenzenesulfonate and 0.5g thiadiazole derivative TH-571 to base oil 35.0g PAO and 44.0g N32 mineral Oil, put it into a reaction kettle with a rotation speed of 2500-4500 rpm for heating and stirring, when the temperature reaches 60-80°C, add 0.8g nano-ZnO and 1.0g nano-MoS 2 , the stirring time is 45-60 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com