Pressing self-locking structure and pressing pen adopting same

A technology of self-locking structure and matching structure, which is applied in printing, writing utensils, writing parts, etc., can solve problems such as energy waste, oil leakage, and pen head wear, and achieve simple and convenient operation, strong flexibility, and reduce unnecessary troublesome effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

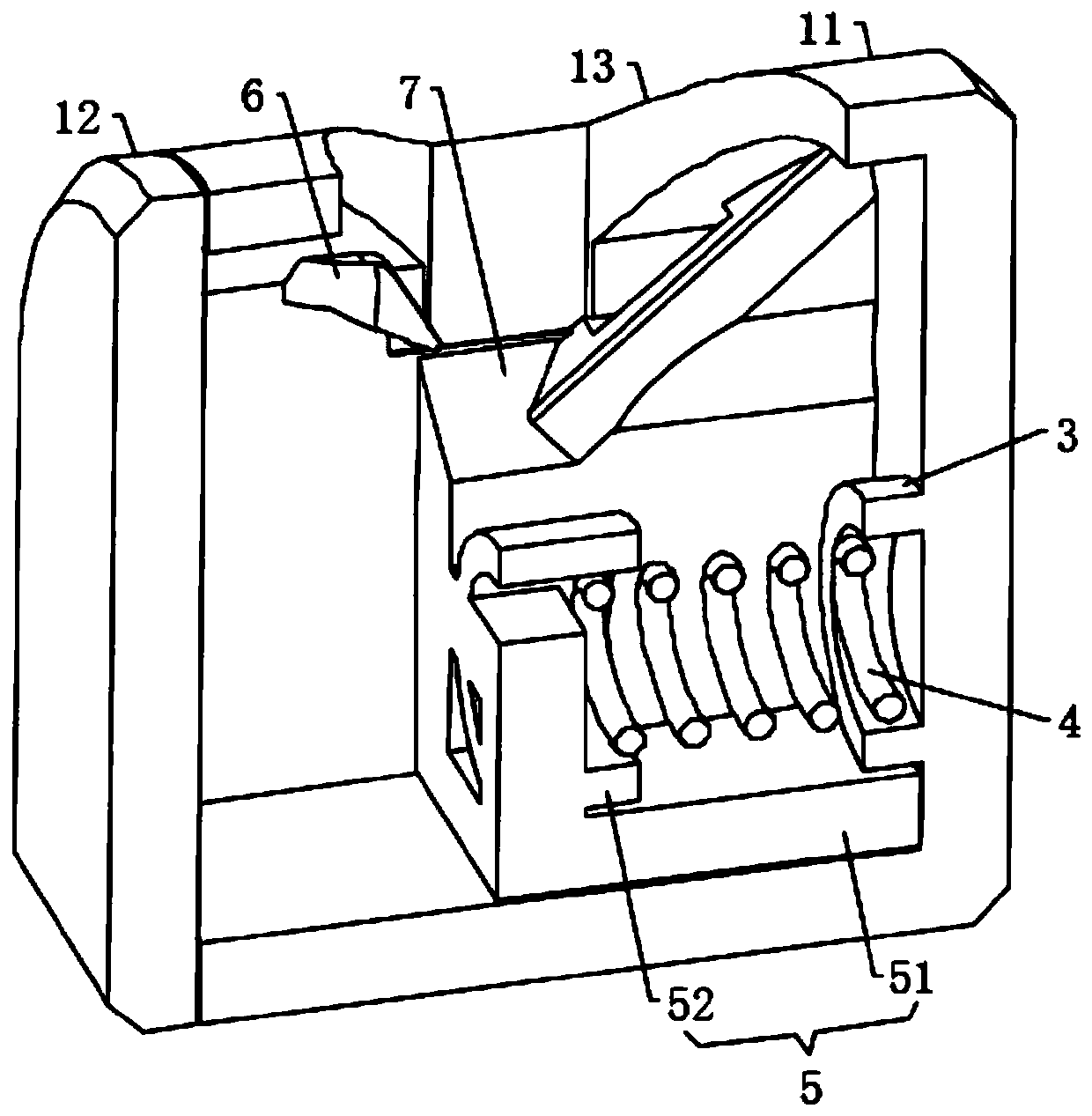

[0049] see Figure 1-8 , a push-to-lock structure, see Figure 1-2 , comprising a left frame body 11 and a right frame body 12 fixed on the rear portion of the left frame body 11, the inside of the left frame body 11 is provided with a sliding connector 5, and the sliding connector 5 is externally connected to an external component during use, and the left frame body 11 3 is fixed on the inner wall of the front part, and a return spring 4 is sleeved between the sliding connector 5 and 3. The sliding connector 5 includes a slider 51 that is slidably connected to the inner bottom of the left frame body 11 and is fixed on the slider 51. The annular positioning block 52 at the front, the return spring 4 is located between the annular positioning block 52 and 3, the slider 51 is located on the lower side of the limiter 6, and the slider 51 is on the left side of the frame when the pressing member 2 is pressed down once. 11 and move forward, while the annular positioning block 52 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com