Pathological tissue dehydration instrument

A tissue and pathological technology, applied in the field of pathological tissue dehydration instrument, can solve the problems of slow dehydration process, inability to use continuous concentration dehydration, poor effect, etc., and achieve the effect of good effect, avoidance of errors and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

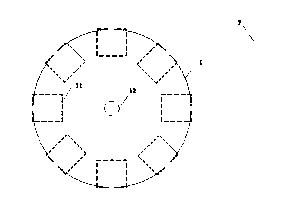

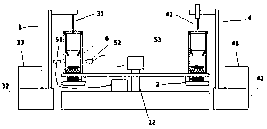

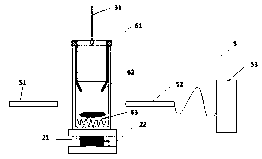

[0037] This embodiment describes the structure of the present invention. combine Figure 1-3 , a pathological tissue dehydration instrument, comprising a shell, a rotating tray 1, a stirring control chassis 2, a liquid injection control module 3, a liquid pumping control module 4, a concentration detection module 5, a dehydration cuvette 6, a main controller 7; a rotating tray 1. The stirring control chassis 2, the liquid injection control module 3, the liquid pumping control module 4, and the concentration detection module 5 are all connected to the main controller 7;

[0038] The rotating tray 1 is provided with a plurality of cuvette stations 11, and the dehydration cuvette 6 is detachably connected to the cuvette stations 11; the rotating tray 1 rotates horizontally under the drive of the rotating motor 12; multiple stirring control The chassis 2 is arranged on the lower side of the rotary tray 1, and corresponds to the position of the cuvette station 11, and the stirring...

Embodiment 2

[0053] This embodiment introduces the method of using the device.

[0054] Step 1. Weigh the mass m of the fixed sample to be dehydrated, and input the weighed mass m and the dehydration coefficient k corresponding to the type of the sample to be dehydrated into the main controller 7;

[0055] Step 2, the main controller 7 calculates the dehydration time t and the concentration endpoints c1 and c2 of the sample to be dehydrated according to m and k; wherein c1 is the lowest concentration value, and c2 is the highest concentration value;

[0056] Among them, t=kt0; t0 is the standard time interval, which is a fixed value, and k is the dehydration coefficient, which is a dimensionless constant, which is related to the difficulty of dehydration of the sample to be dehydrated and can be adjusted manually; c1 and c2 are the Two concentration constants related to the type of sample;

[0057] Step 3, the main controller 7 controls the rotating tray 1 to rotate, and drives an empty d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com