Prefabricated structural surface concrete single-hole blasting test device and test method

A prefabricated structure and blasting test technology, applied in the direction of measuring devices, optical devices, electromagnetic measuring devices, etc., to achieve the effects of strong practicability, improved energy utilization rate and rock breaking efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

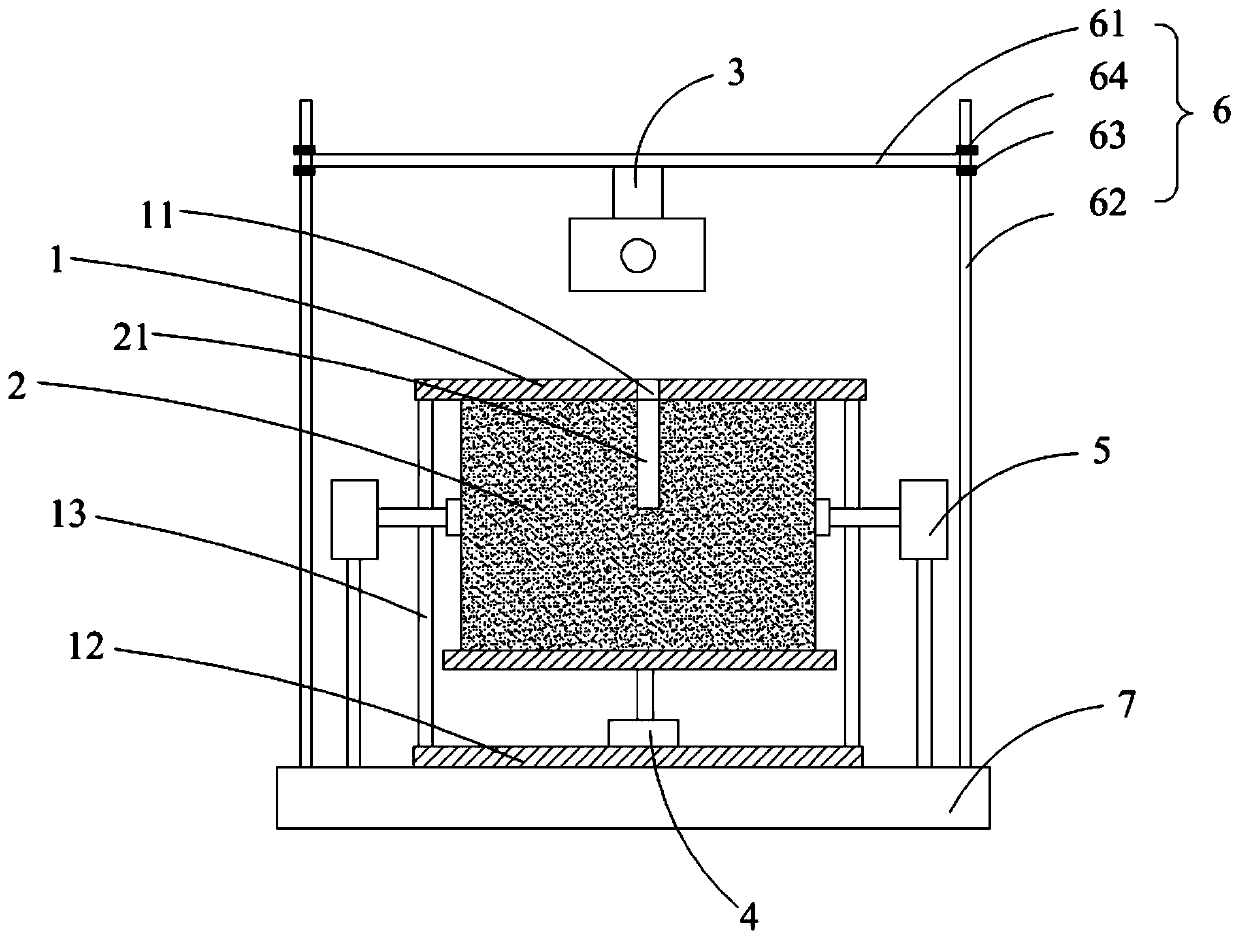

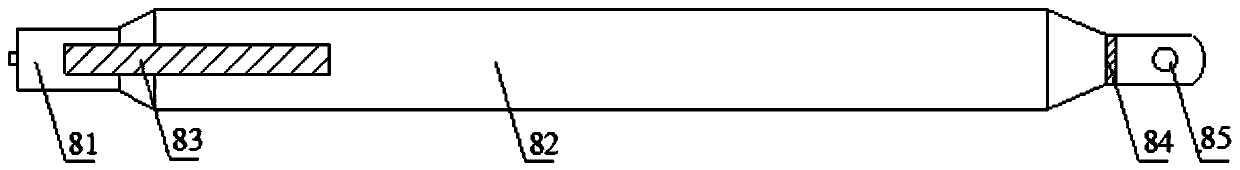

[0048] See figure 1 and figure 2 , the embodiments of the present invention provide a prefabricated structural surface concrete single-hole blasting test device, including a test box 1, a concrete specimen 2, a CO 2 Phase change cracker, foil resistance strain gauge, high-speed digital camera 3, pressure device, digital image processing system and ultra-dynamic strain testing system.

[0049] See figure 1 , the test box 1 has a space for accommodating the concrete specimen 2, the middle part of the concrete specimen 2 is drilled with a blast hole 21, and the top surface is provided with a plurality of circular speckles, the diameter of which is 0.25mm ~0.5 mm, the top of the test box 1 is transparent, and a perforation 11 opposite to the blast hole 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com