A non-woven fabric cutting machine

A technology of cloth cutting machine and cutting shaft, which is applied in textiles and papermaking, textile material cutting, thin material processing, etc. It can solve the problems of reducing work efficiency and increasing the labor intensity of operators, so as to improve production efficiency and cutting quality , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

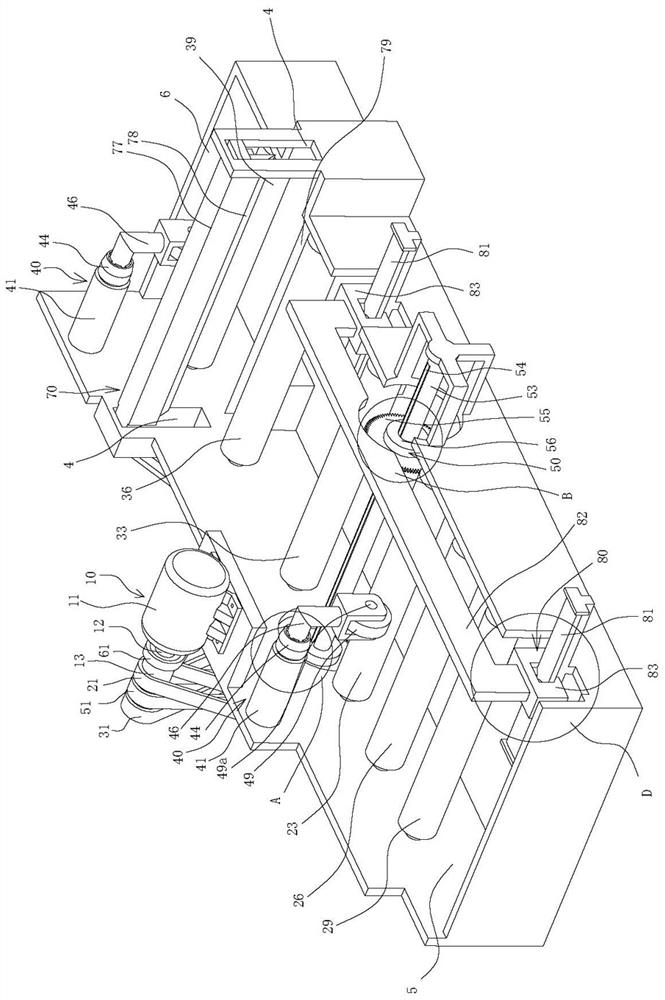

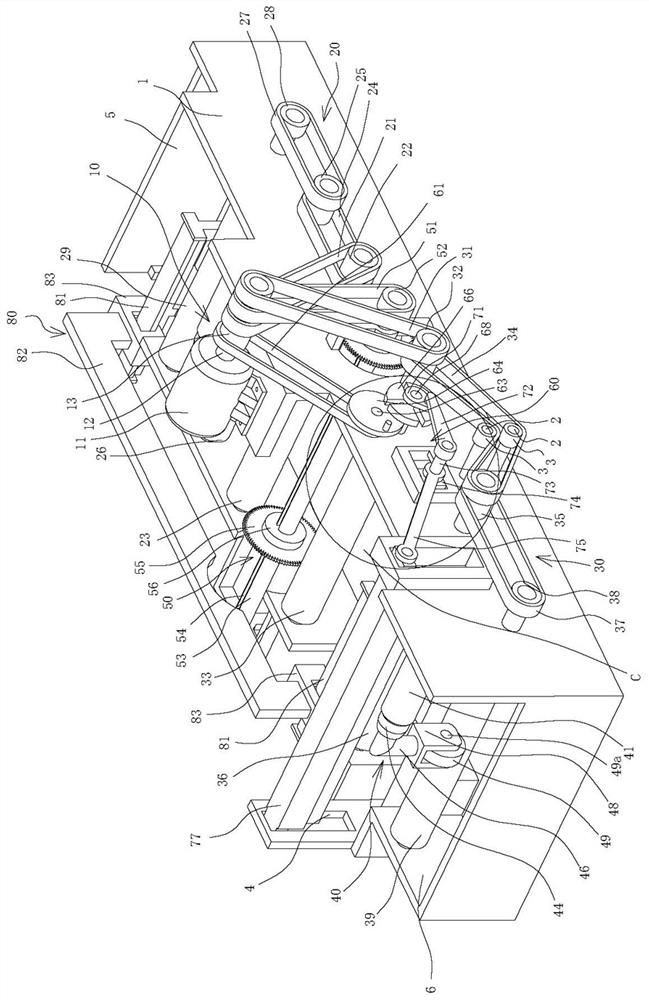

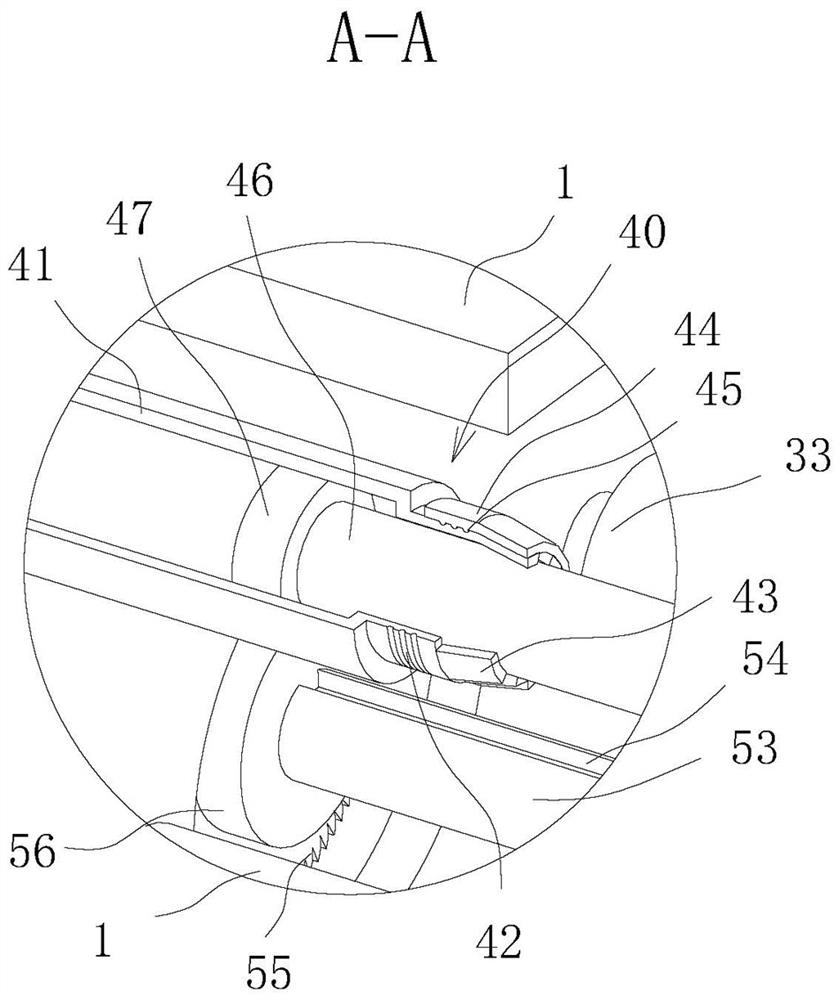

[0029] Such as figure 1 with figure 2 As shown, the non-woven fabric cutting machine of the present invention comprises a frame 1, the left side of the frame 1 is provided with a material inlet 5, the right side of the frame 1 is provided with a discharge port 6, and the upper end of the frame 1 is provided with a power mechanism 10, and the power The left side of the mechanism 10 is provided with a first conveying mechanism 20, the right side of the first conveying mechanism 20 is provided with a second conveying mechanism 30, the second conveying mechanism 30 is connected with the power mechanism 10, and the upper end of the frame 1 is provided with two fixing mechanisms 40, The lower end of the power mechanism 10 is provided with a cutting mechanism 50, the right side of the power mechanism 10 is provided with a rotating mechanism 60 capable of intermittent rotation, the right end of the rotating mechanism 60 is provided with a shearing mechanism 70, and the rear end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com