Bagging and packaging integrated equipment for spicy food

A food and spicy technology, which is applied in the field of bagging and packaging integrated equipment for spicy food, can solve the problems of reducing overall packaging efficiency, low equipment utilization efficiency, and manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

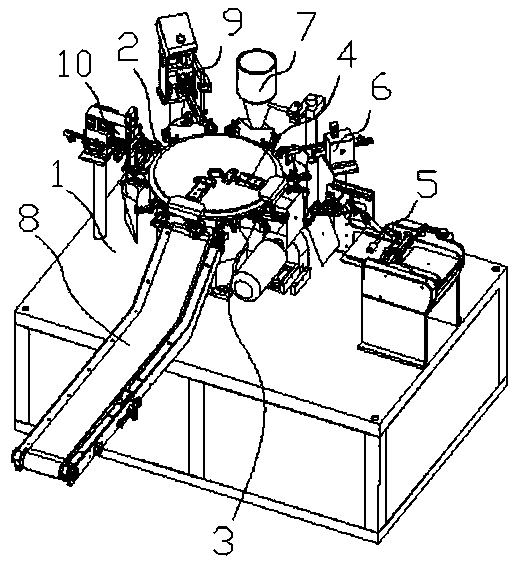

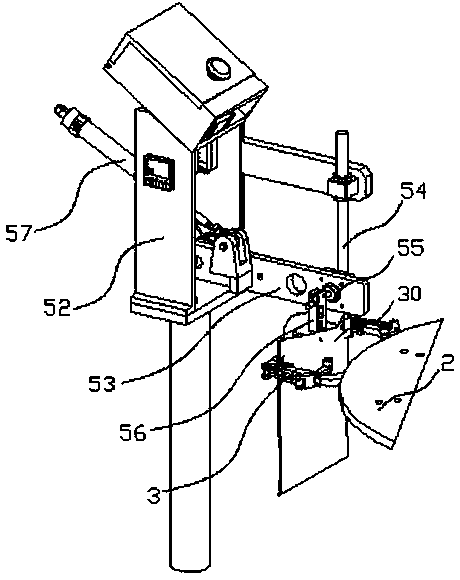

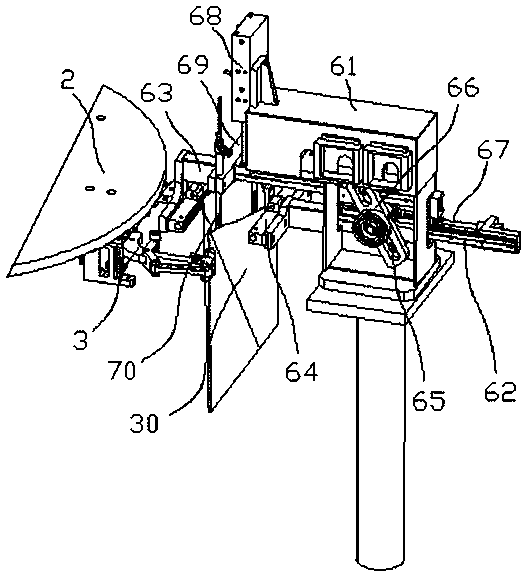

[0023] like Figure 1-2 Shown, the specific structure of the present invention is: a kind of bagging and encapsulating integrated equipment of hot and spicy food, comprises frame 1, and described frame 1 is provided with the turntable 2 of matching driving structure, and uniform on the described turntable 2 A clamping device 3 cooperating with the packaging bag 30 is provided, and a bag-loading device 5 cooperating with the clamping device 3, a bag opening device 6, a bagging device 7, and a pressing device are sequentially arranged on the frame 1 along the rotation direction of the turntable 9. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com