Combined butt-joint connecting device for vehicle-mounted baggage carrier

A docking device and luggage rack technology, which is applied to vehicle components, transportation and packaging, and additional accessories, can solve problems such as the inability to meet the extremely high requirements for the reliability and flatness of the luggage rack connection, safety hazards, etc., and achieve load safety Sexuality and visual aesthetic requirements, easy installation, and easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

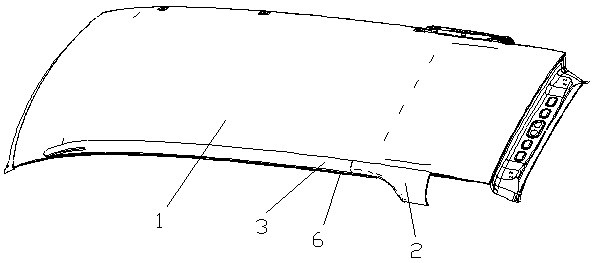

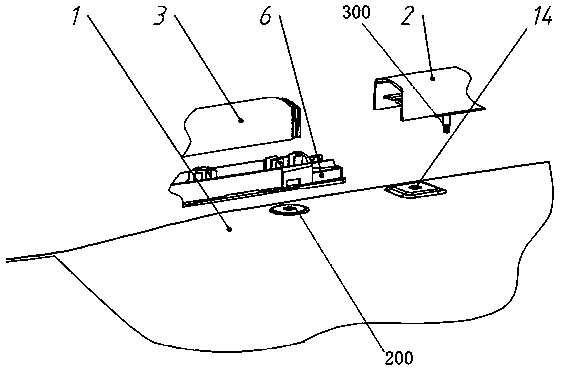

[0039] Please see attached figure 1 And attached figure 2 , a combined docking device for a vehicle-mounted luggage rack, comprising a luggage rack load-bearing beam 2, an end cover trim 3 and an end cover base 6; the end cover base 6 is fixedly installed on the vehicle body roof 1 through an end cover base fastening assembly 200 Specifically, it can be installed at the junction of the vehicle body roof 1 and the side wall. The luggage rack load-bearing beam 2 is fixedly installed on the vehicle body roof 1 through the load-bearing beam fastening assembly 300. The luggage rack load-bearing beam 2 and the end cover trim 3 They are respectively installed on the end cover base 6 and docked with each other.

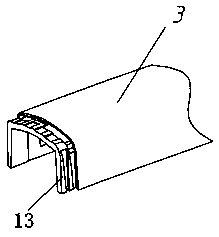

[0040] Please see attached image 3 , the longitudinal section of the end cover trim 3 is n-shaped, and the bottoms of the two side panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com