Excavator base

An excavator and base technology, applied in the field of mechanical processing equipment, can solve the problems of inactivity, shrinking construction machinery market sales, and inability to adjust the height, and achieve the effect of overcoming the inability to adjust the height of the base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

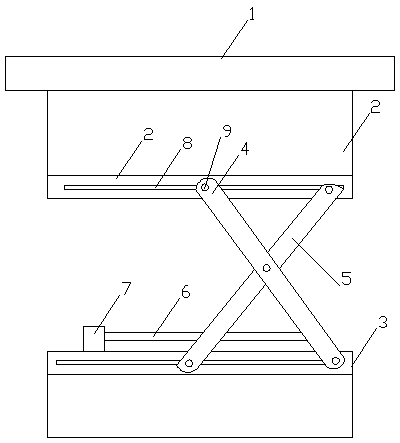

[0017] An excavator base, characterized in that it includes a base body 1, a mounting frame 2 is provided at the bottom of the base body 1, a lifting device is installed under the mounting frame 2, and a lifting device is installed at the bottom of the lifting device. Fixed frame 3, described lifting device comprises the first lifting rod 4 and the second lifting rod 5 that are arranged crosswise, the middle part of described first lifting rod 4 and the second lifting rod 5 are mutually hinged, and described first lifting rod 4 The bottom of the second lifting rod 5 is connected with the first connecting rod 6, and the outside of the second lifting rod 5 is connected with a cylinder 7, and the cylinder 7 is connected with the second lifting rod 5 through a connecting rod. The base body 1 of the present application can achieve the effect of raising and lowering according to actual needs, and overcomes the problem that the height of the base cannot be adjusted in the prior art. ...

Embodiment 2

[0019] An excavator base, characterized in that it includes a base body 1, a mounting frame 2 is provided at the bottom of the base body 1, a lifting device is installed under the mounting frame 2, and a lifting device is installed at the bottom of the lifting device. Fixed frame 3, described lifting device comprises the first lifting rod 4 and the second lifting rod 5 that are arranged crosswise, the middle part of described first lifting rod 4 and the second lifting rod 5 are mutually hinged, and described first lifting rod 4 The bottom of the second lifting rod 5 is connected with the first connecting rod 6, and the outside of the second lifting rod 5 is connected with a cylinder 7, and the cylinder 7 is connected with the second lifting rod 5 through a connecting rod.

[0020] There are two groups of lifting devices, and the two groups of lifting devices are symmetrically distributed.

[0021] The cylinder 7 is fixed on the fixed frame 3 .

[0022] The bottom of the insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com