Auxiliary troubleshooting system for master control room

A main control room and troubleshooting technology, applied in transmission systems, switchgear, electrical components, etc., can solve problems such as labor consumption, equipment short-circuit, danger, etc., and achieve the effect of reducing running time, saving labor costs, and shortening analysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples.

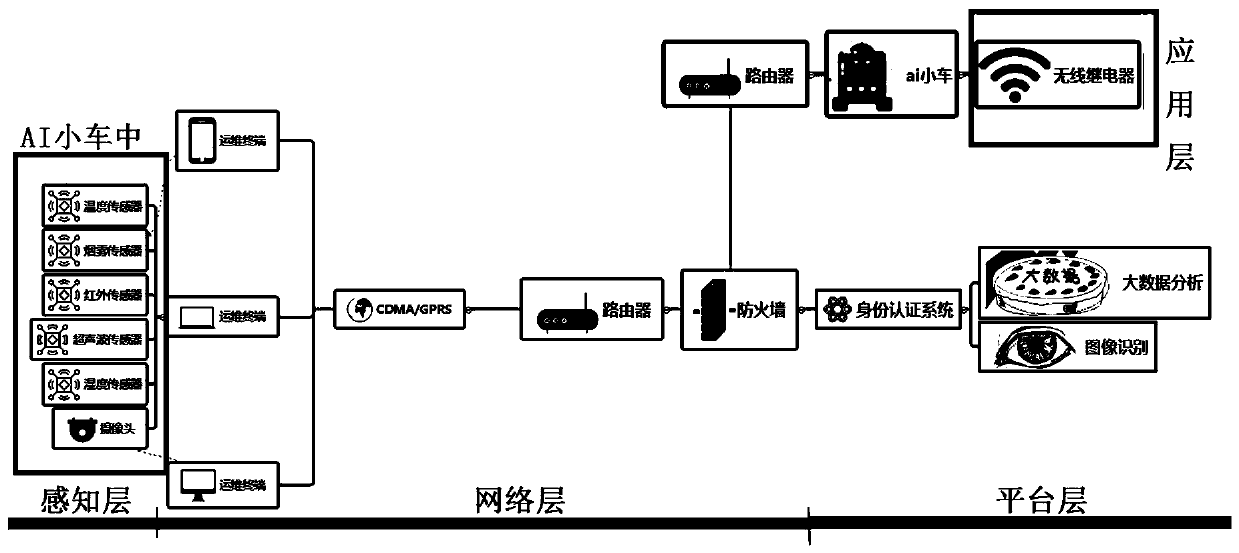

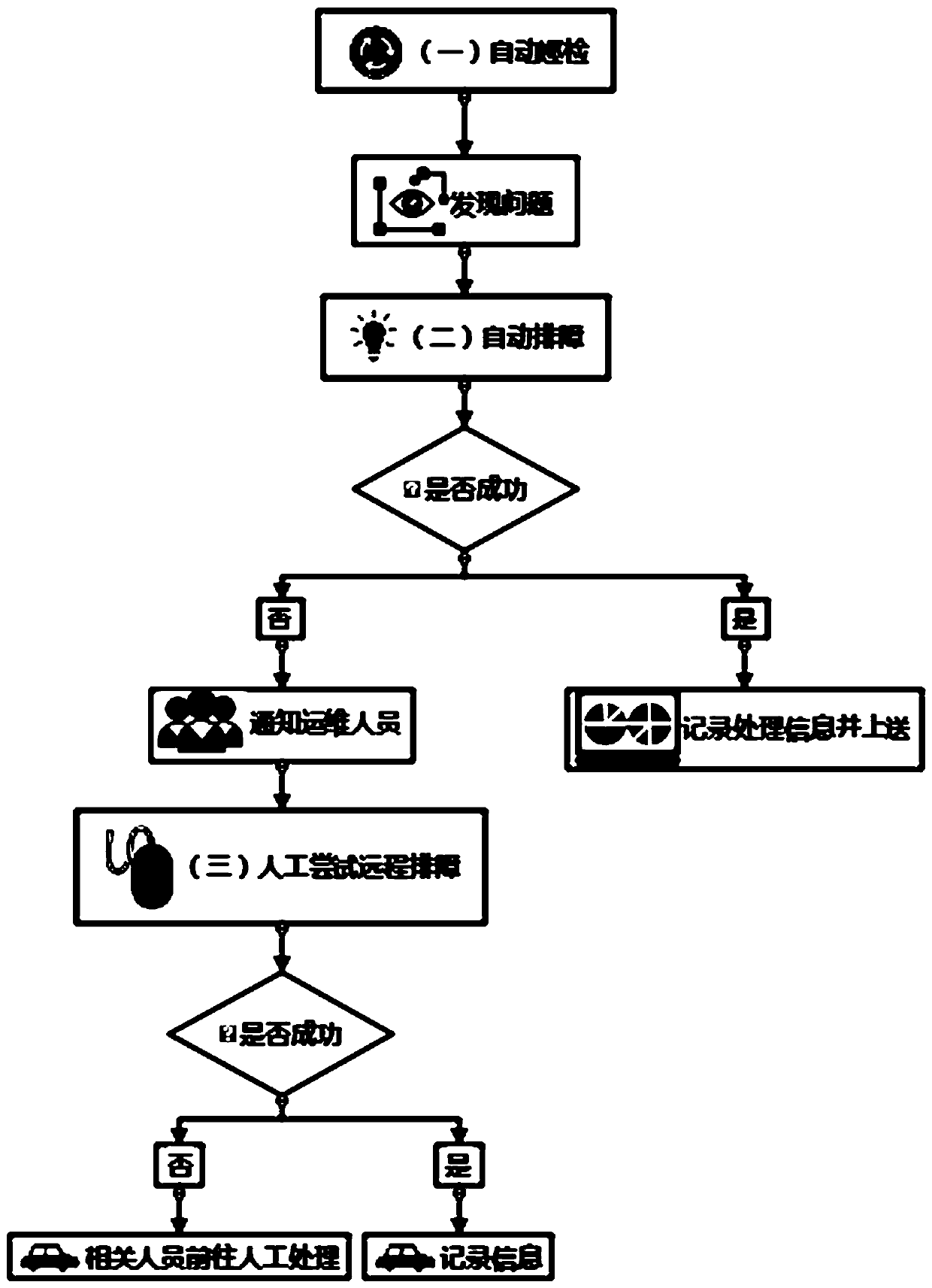

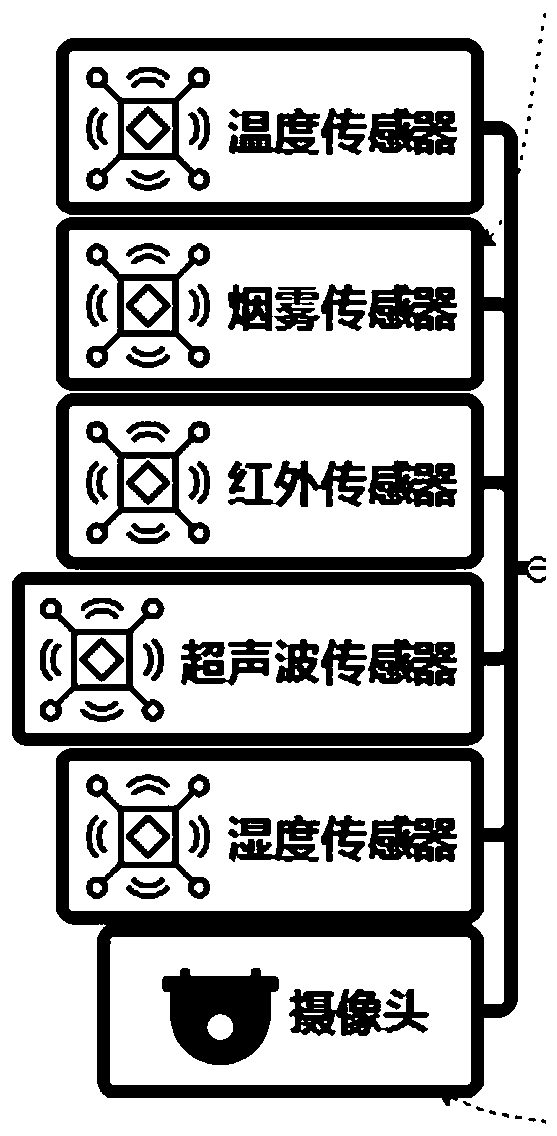

[0033] An auxiliary troubleshooting system for the main control room, such as Figure 1~Figure 11 As shown, it includes an AI robot car. The AI robot car includes a carrying platform and two pairs of wheels. The two pairs of wheels are installed side by side on the lower part of the carrying platform. A power module is provided on the carrying platform. 12V wireless charging module, the wireless charging module continues to charge when the car is running; the troubleshooting system is realized through four layers, including the perception layer, network layer, platform layer and application layer. The sensing layer includes an infrared line inspection module, an infrared obstacle avoidance module, an ultrasonic obstacle avoidance module, a network camera, a temperature sensing module, a humidity sensing module, and a smoke sensing module, and each module of the sensing layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com