A Pipeline Stress Internal Detection Method Based on Complex Stress State Model

A technology of complex stress and state models, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the complicated stress on the pipe wall, limit the application of magnetic field weakening method, and fail to meet the detection signal recognition Requirements and other issues to achieve the effect of judgment detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

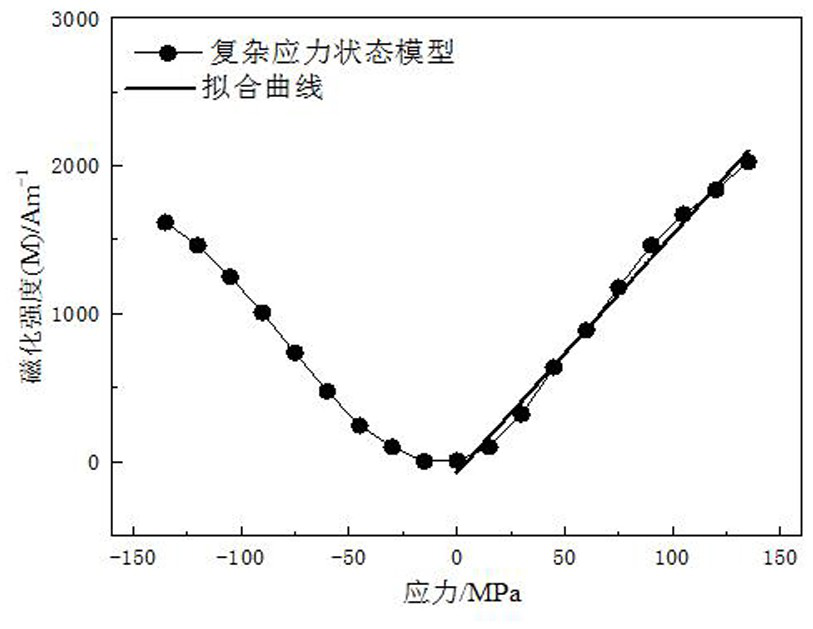

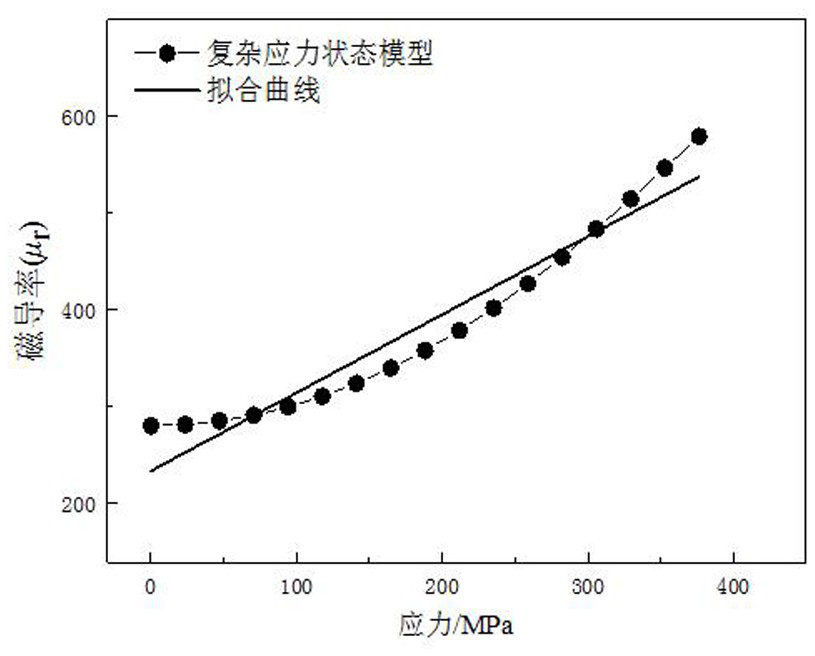

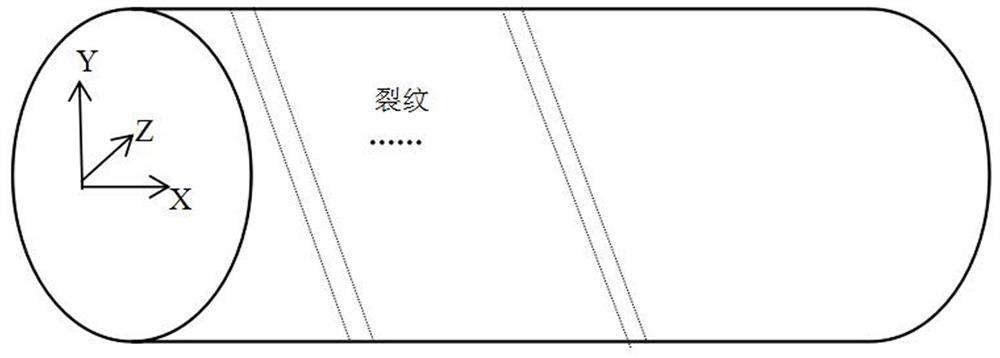

[0087] A pipeline stress internal detection method based on a complex stress state model, the method steps are as follows:

[0088] The first step: use the detection equipment probe to collect the weak magnetic signal; (the real-time magnetic field signal on the surface of the pipeline is collected)

[0089] Step 2: Input the signal collected in the first step into the constructed complex stress state model to obtain the change of pipeline stress;

[0090] The third step: identify the pipeline stress concentration area according to the pipeline stress change in the second step.

[0091] The complex stress state model of the second step is:

[0092]

[0093] The method for constructing the complex stress state model is as follows: Suppose the entire system is subjected to the combined action of the external magnetic field H and the stress σ, and the effect of the stress on the magnetization of the system is equivalent to an external magnetic field H. σ , represented by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com