Numerical control machine tool control method based on energy consumption optimization and numerical control machine tool

A technology of numerical control machine tools and control methods, applied in computer control, program control, general control systems, etc., can solve the problems of rare reports on cutting power and energy consumption, complex power characteristics, etc., and achieve improved efficiency, reduced energy consumption, and precise The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

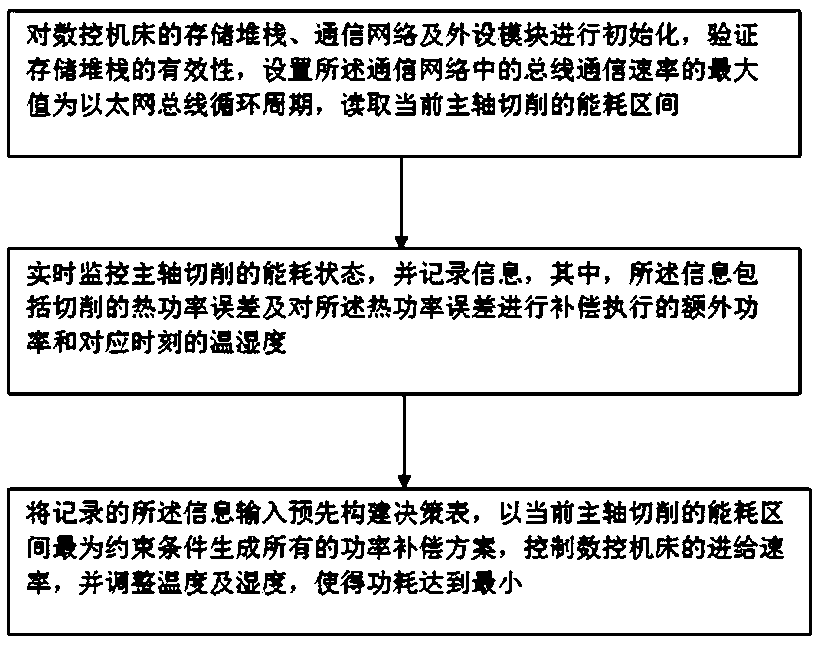

[0021] Such as figure 1 A control method for a CNC machine tool based on energy optimization as shown includes the following steps: Step 1, initialize the storage stack, communication network and peripheral modules of the CNC machine tool, verify the validity of the storage stack, and set the communication network The maximum value of the bus communication rate in is the cycle period of the Ethernet bus, and reads the energy consumption interval of the current spindle cutting; step 2, establishes a monitoring module, monitors the energy consumption status of the spindle cutting in real time, and records information, wherein the information Including the thermal power error of cutting and the additional power executed to compensate the thermal power error and the temperature and humidity at the corresponding time; step 3, input the recorded information into the pre-built decision table, and the energy consumption interval of the current spindle cutting is the most The constrain...

Embodiment 2

[0028]This embodiment focuses on describing the CNC machine tool provided by the present invention from the perspective of hardware, and provides a CNC machine tool that optimizes energy consumption, including a CNC machine tool, a network module, a monitoring module, a peripheral module, and an analysis module. , the communication network and the peripheral modules are initialized, the validity of the storage stack is verified, the maximum value of the bus communication rate in the communication network is set as the Ethernet bus cycle period, and the energy consumption interval of the current spindle cutting is read; the monitoring module, Monitor the energy consumption status of the spindle cutting in real time, and record information, wherein the information includes the thermal power error of cutting, the additional power executed to compensate the thermal power error, and the temperature and humidity at the corresponding time; the analysis module will record the The infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com