Markers and methods for screening high-flavor tea tree resources suitable for oolong tea production

A technology of tea tree resources and oolong tea, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., to achieve the effect of simple operation, less sample required and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

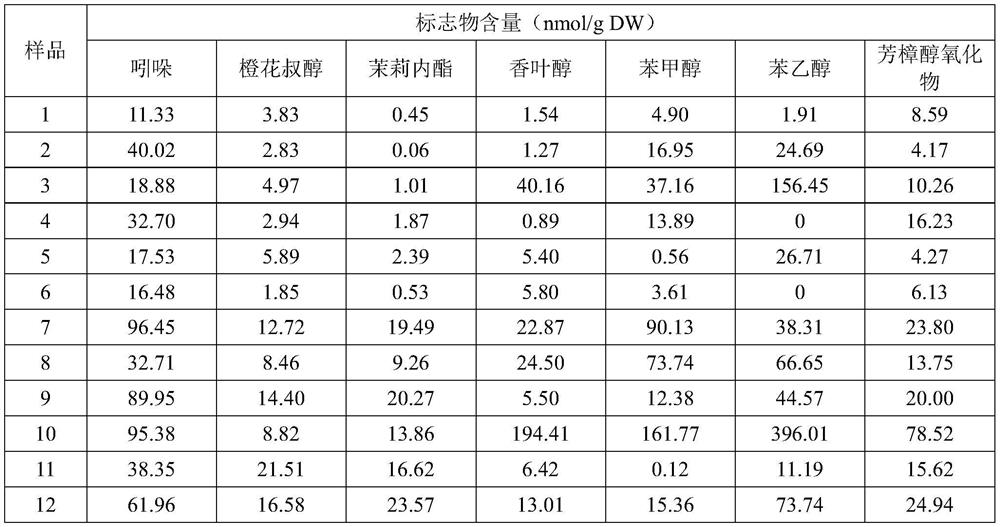

[0038] Screening method of high-flavor tea tree resources suitable for making oolong tea

[0039] 1. Sample pretreatment

[0040] The picked fresh tea leaves (10-15g) were stacked at 25°C for 3 hours, immediately put into liquid nitrogen after processing, and quickly frozen, and stored at -80°C.

[0041] 2. Extraction and determination of aroma substances

[0042] After the sample was ground into powder in liquid nitrogen, 500 mg of tea powder was weighed, placed in an extraction bottle, and 2 mL of dichloromethane (ether or ethyl acetate) and 5 nmol of ethyl caprate (as an internal standard) were added. Extract under overnight shaking. The next day, it was dried with anhydrous sodium sulfate, and then concentrated to about 200 μL using a nitrogen blower (MIULAB NDK200-1; Miou Instruments, Hangzhou, China). The concentrate was analyzed by GC-MS (QP2010 SE; Shimadzu Corporation, Tokyo, Japan) to quantify indole, nerolidol, and jasmonolide in the concentrate.

[0043] The an...

Embodiment 2

[0048] Screening method of high-flavor tea tree resources suitable for making oolong tea

[0049] 1. Sample pretreatment

[0050] The picked fresh tea leaves (10-15g) were stacked at 25°C for 3 hours, immediately put into liquid nitrogen after processing, and quickly frozen, and stored at -80°C.

[0051] 2. Extraction and determination of aroma substances

[0052] After the two-treated sample was ground into powder in liquid nitrogen, 500 mg of tea powder was weighed, placed in an extraction bottle, and 2 mL of dichloromethane (ether or ethyl acetate) and 5 nmol of ethyl caprate (as internal label) and extracted with shaking overnight at room temperature. The next day, it was dried with anhydrous sodium sulfate, and then concentrated to about 200 μL using a nitrogen blower (MIULAB NDK200-1; Miou Instruments, Hangzhou, China). The concentrate was analyzed by GC-MS (QP2010 SE; Shimadzu Corporation, Tokyo, Japan) to quantify geraniol, benzyl alcohol, and phenethyl alcohol in t...

Embodiment 3

[0058] Screening method of high-flavor tea tree resources suitable for making oolong tea

[0059] 1. Sample pretreatment

[0060] The picked fresh tea leaves (10-15g) were stacked at 25°C for 3 hours, immediately put into liquid nitrogen after processing, and quickly frozen, and stored at -80°C.

[0061] 2. Extraction and determination of aroma substances

[0062] After the sample was ground into powder in liquid nitrogen, 500 mg of tea powder was weighed, placed in an extraction bottle, and 2 mL of dichloromethane (ether or ethyl acetate) and 5 nmol of ethyl caprate (as an internal standard) were added. Extract under overnight shaking. The next day, it was dried with anhydrous sodium sulfate, and then concentrated to about 200 μL using a nitrogen blower (MIULAB NDK200-1; Miou Instruments, Hangzhou, China). The concentrate was analyzed by GC-MS (QP2010 SE; Shimadzu Corporation, Tokyo, Japan) to quantify linalool oxide, geraniol, and benzyl alcohol in the concentrate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com