Control method of clothes treating device

The technology of a clothing processing device and a control method is applied in the fields of drying, nursing processing, and clothing washing, which can solve the problems of wrinkled and unsightly clothing, and achieve the effects of good molding, increased deformation plasticity, and reduced frictional force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

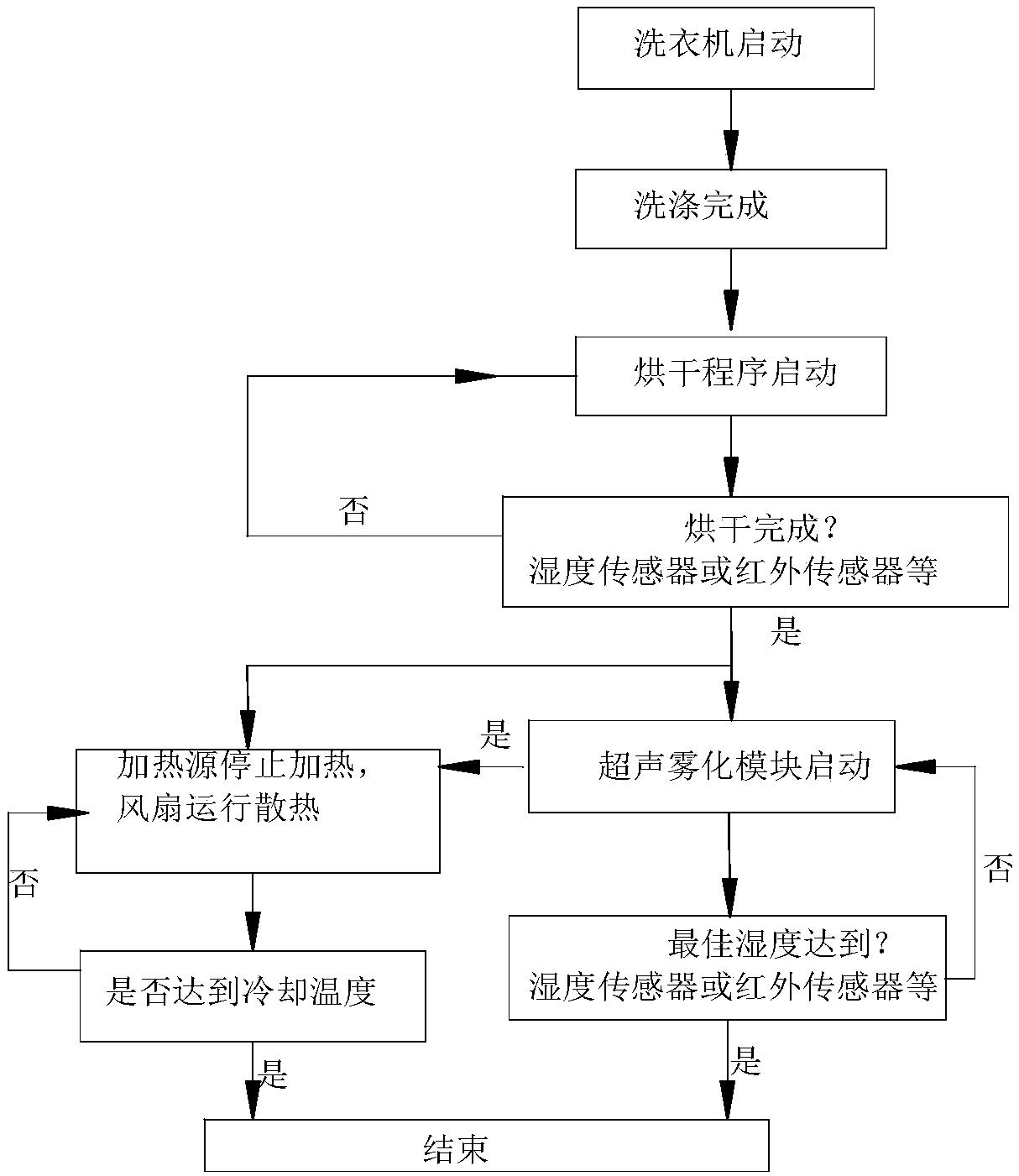

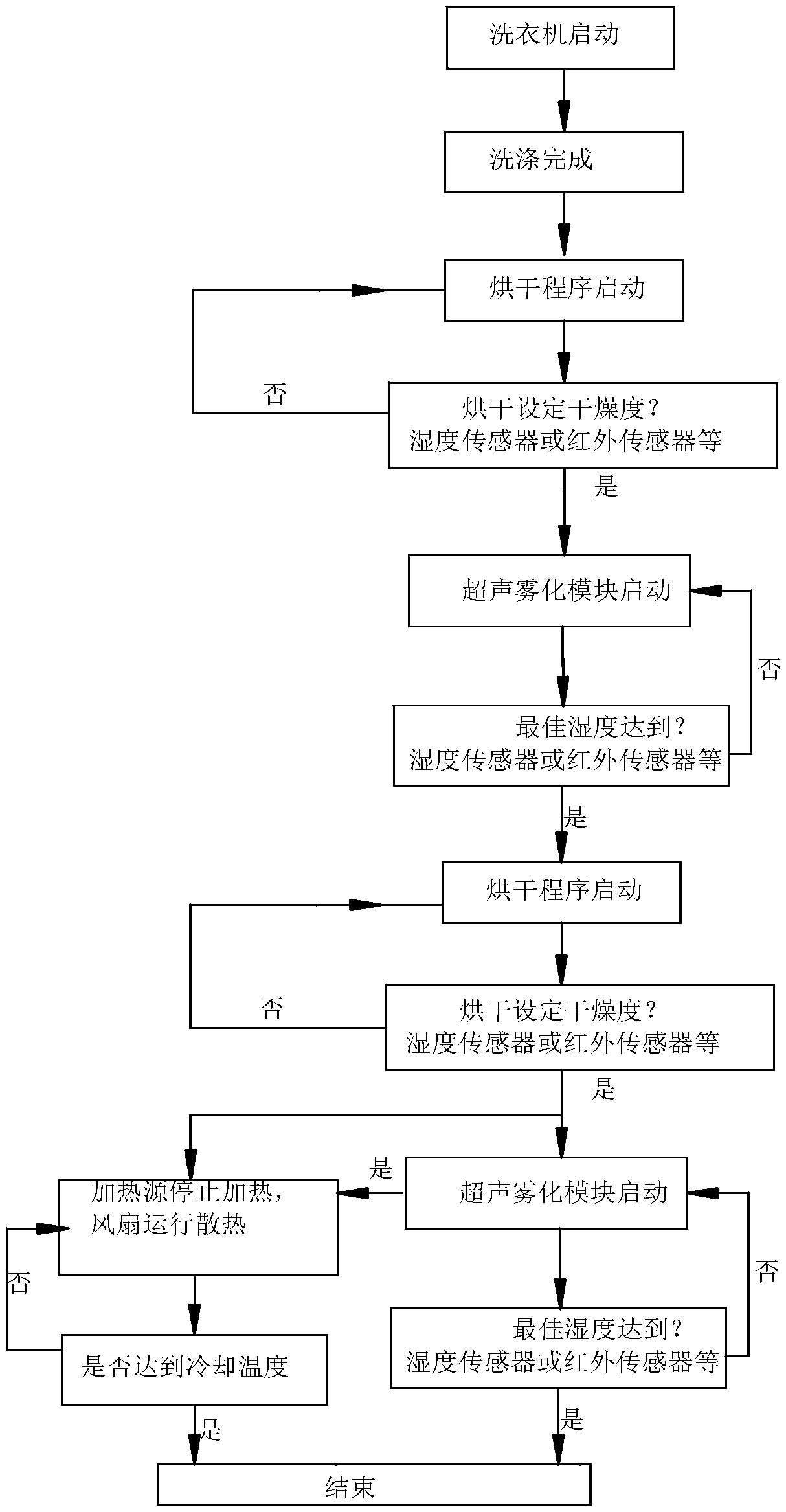

[0040] Such as Figure 1-Figure 3 As shown, the laundry treatment device of this embodiment includes:

[0041] A processing cylinder assembly, in which the clothes to be processed are accommodated;

[0042] The atomization module is used to generate atomized water and pass it into the inside of the treatment cylinder assembly.

[0043] The control method of the clothes treatment device in this embodiment includes:

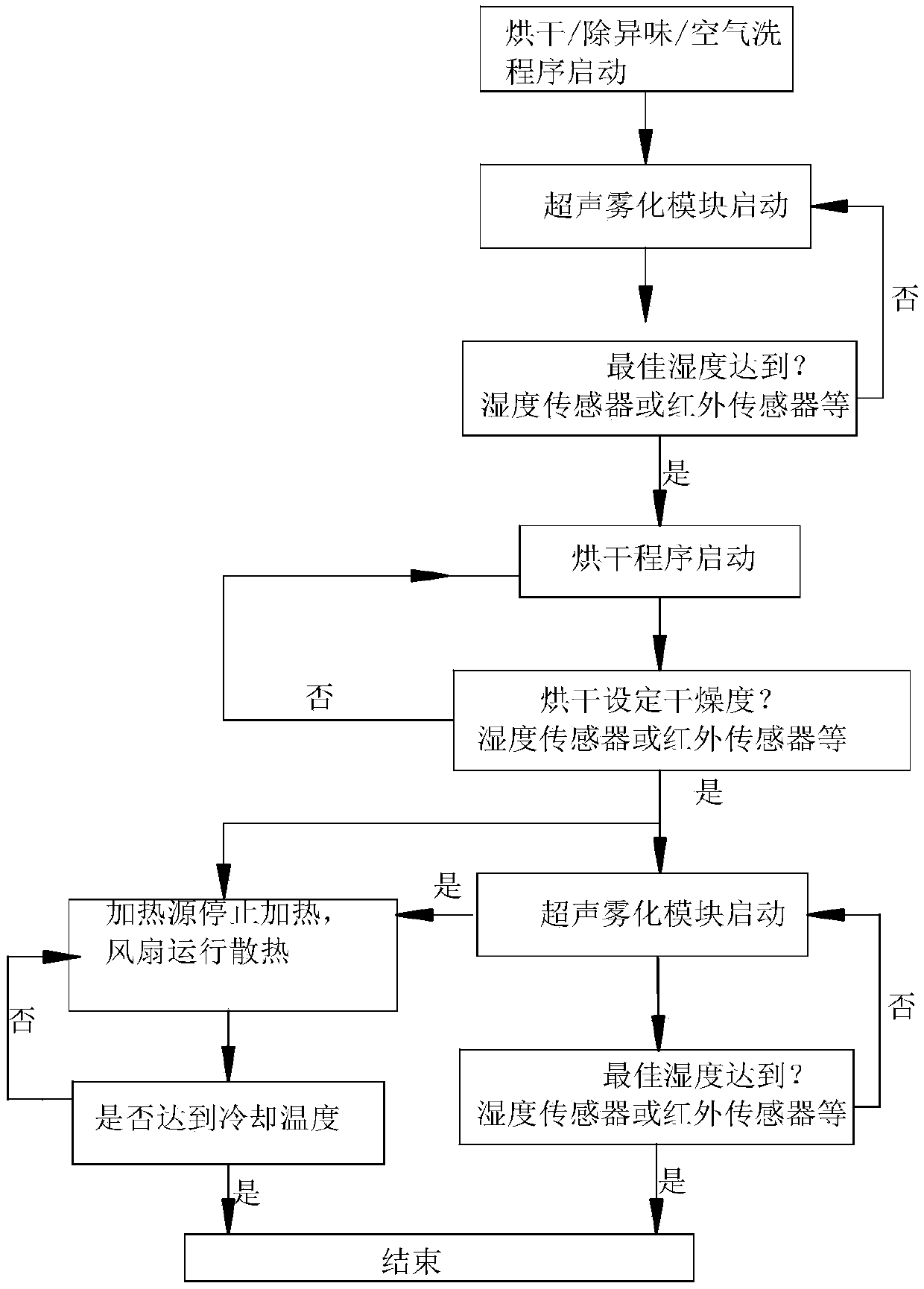

[0044] When the laundry treatment device executes the drying program, and / or steam washing program, and / or air washing program, and / or odor removal program, when the humidity of the clothes reaches the set humidity value, the control atomization module starts to generate atomized water into Go into the treatment cylinder assembly to spray the clothes.

[0045] In the control method of the clothes treatment device in this embodiment, during the drying program, and / or the steam washing program, and / or the air washing program, and / or the odor removal program, the m...

Embodiment 2

[0068] Such as Figure 4-Figure 7 Shown, a kind of clothes treatment device of this embodiment comprises:

[0069] A processing cylinder assembly, in which the clothes to be processed are accommodated;

[0070] The atomization module 200 includes an atomization water storage device 201 and an atomization generating device. The atomization water storage device 201 has an atomization water storage chamber 2011 for storing atomization water and an atomization water storage chamber 2011 communicated with the treatment cartridge assembly. The atomization water output end 2016, the atomization generating device is arranged outside the atomization water storage chamber 201, the energy output end of the atomization generation device 201 acts on the atomization water in the atomization water storage chamber 2011 to convert it into water The mist enters the treatment cylinder assembly through the atomized water output port 2016 to perform the atomization treatment of the clothes.

[0...

Embodiment approach

[0090] As an embodiment of this embodiment, the atomized water storage device 201 includes a housing 2014 with an open chamber and a cover body 2012 that is mounted on the opening of the housing 2014, and the cover body 2012 and the housing 2014 Together, they form the atomized water storage chamber 2011 .

[0091] The atomized water inlet port 2017 is the atomized water inlet port provided on the cover, the atomized water output port 2016 is the atomized water output port provided on the side wall of the housing 2014, and the The air inlet 2013 is an air inlet provided on the side wall of the casing 2014, and the atomized water output port and the air inlet are both located above the highest water level in the atomized water storage chamber 2011. Preferably, the The atomized water output port is arranged opposite to the air inlet, so that the water mist can be better discharged from the atomized water output port under the action of the air flow.

[0092] The installation po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com