Intermittent type continuous material dipping device

A batch-type, dipping technology, applied in the direction of mixed material pretreatment, chemical instruments and methods, mixers with rotating containers, etc., can solve the problems of high labor costs, etc., to achieve convenient operation, avoid manual pouring, and overall structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

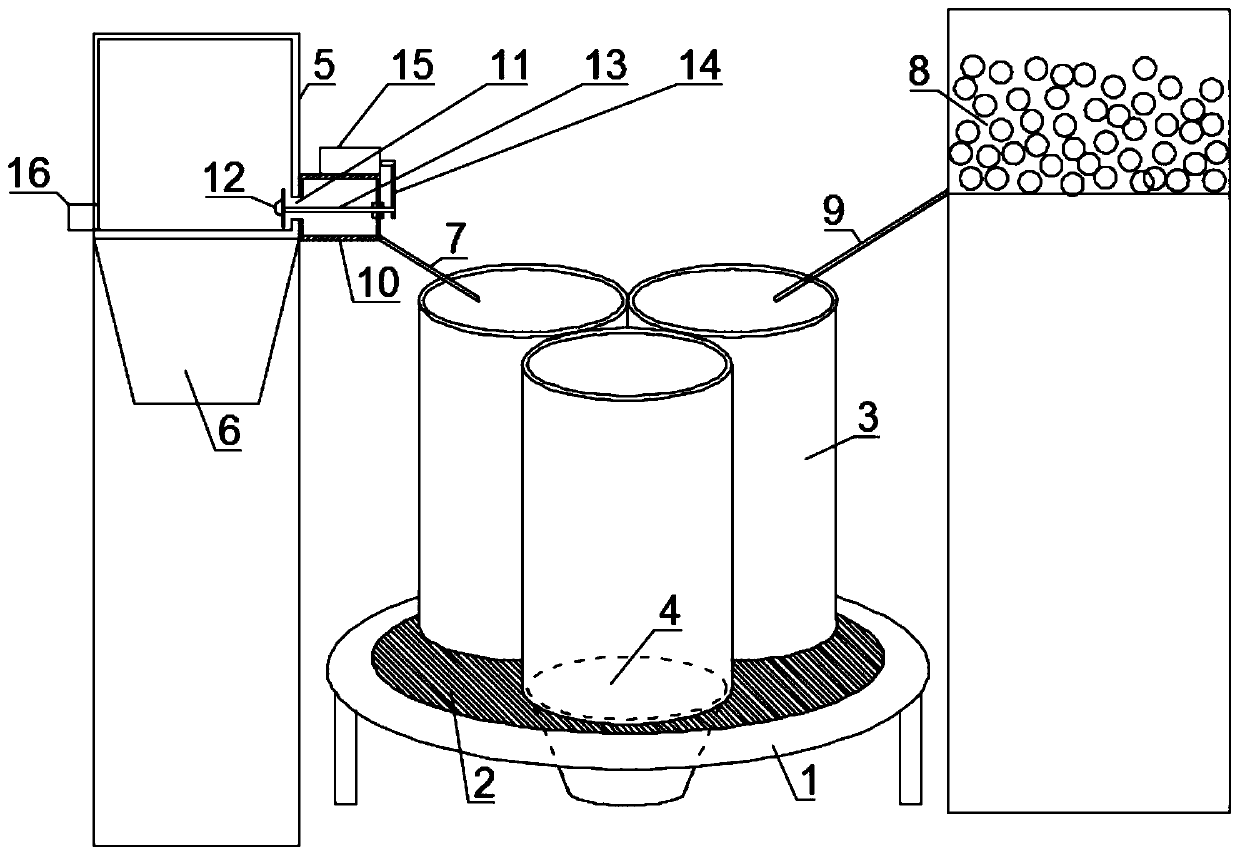

[0019] combined with figure 1 , in this embodiment, a batch-type continuous dipping device is provided, comprising a first support (for supporting equipment thereon), a first disc 1 is fixedly installed on the top of the first support, and the first disc 1 The top is rotated and stacked with a second disk 2 coaxially distributed with it, and the second disk 2 is driven by an external drive device to perform a gap rotation around the axis;

[0020] The arrangement of the second disc 2 stacked on the first disc 1 can minimize the outflow of material liquid;

[0021] Particularly, in the present embodiment, the rotating shaft is installed at the bottom of the center of the second disc 2, and the bottom end of the rotating shaft passes through the first disc 1 and is arranged directly below it (the top end of the rotating shaft is sleeved with a bearing, and the bearing is fixedly installed on the first disc 1). disc 1, thereby reducing the friction between the two), the bottom e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com