A small-diameter downhole rock slag cleaning tool in deep well section

A small-caliber, rock slag technology, which is applied in wellbore/well components, flushing wellbore, earthwork drilling and mining, etc., can solve the problems of small amount of slag removal, inability to completely remove coarse slag, and low efficiency of slag removal. Achieve the effects of not easy to lose, good storage state, and low moisture content of rock slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

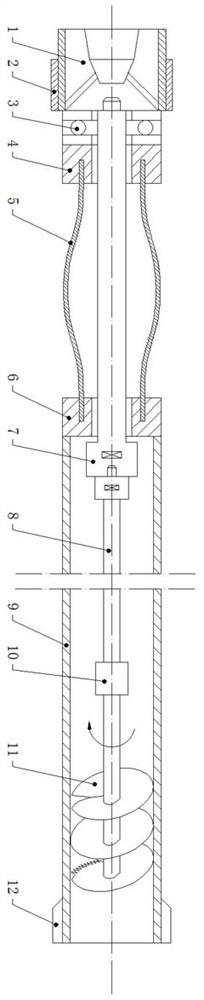

[0020] Such as figure 1 Shown is a small-diameter downhole rock slag removal tool in the deep well section, which includes a water distribution joint 1, a support spring 5, a rock slag holding pipe 9 and a spiral wing drill bit 11, wherein:

[0021] The upper end of the water distribution joint 1 is connected with the drill string, the outer circular surface of the lower part of the water distribution joint 1 is covered with a gauge sleeve 2, and the lower end surface of the water distribution joint 1 is equipped with a thrust bearing 3 upper thrust plate, The lower thrust plate of the thrust bearing 3 is installed on the upper joint 4 of the supporting spring piece, one end of the supporting spring piece 5 is fixedly installed on the upper joint 4 of the supporting spring piece, and the other end of the supporting spring piece 5 is fixedly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com