Motor intermediate shaft turning tooling device

A technology for intermediate shafts and turners, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as the mismatching of intermediate shaft turning methods, and achieve ease of operation difficulty, friction reduction, and accurate installation positions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

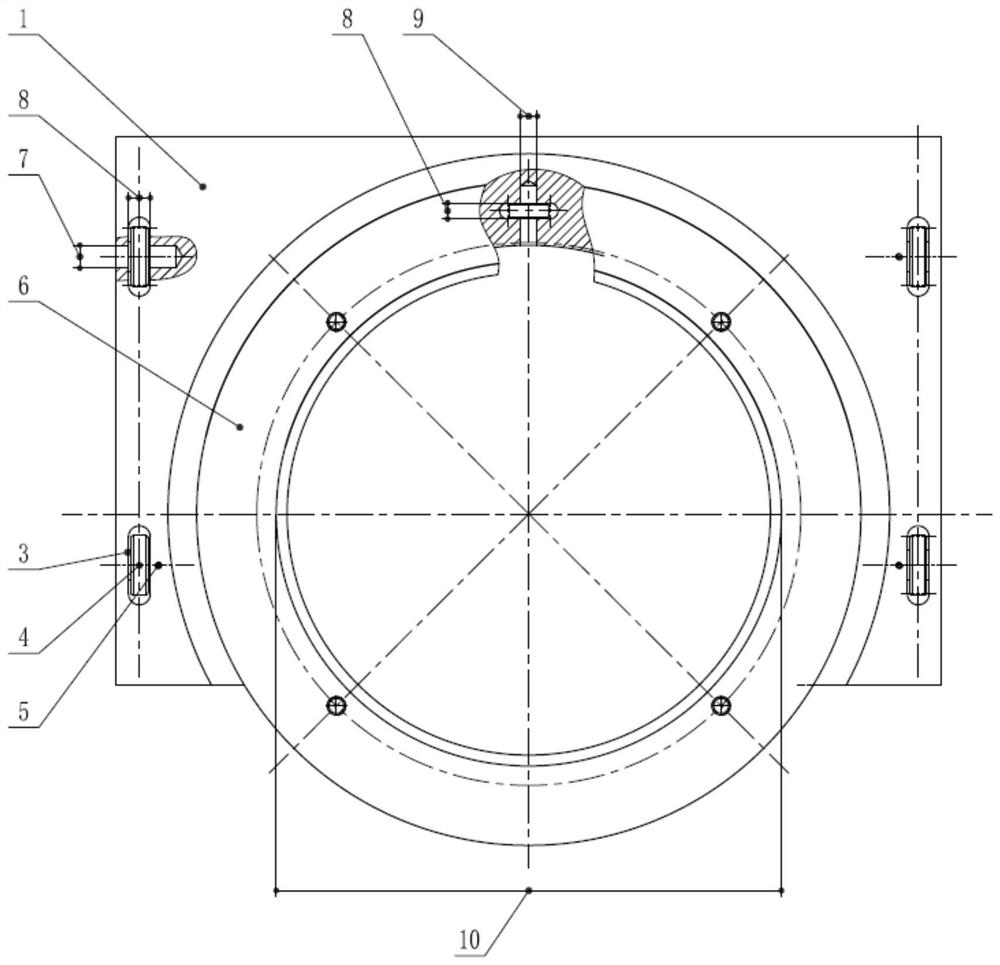

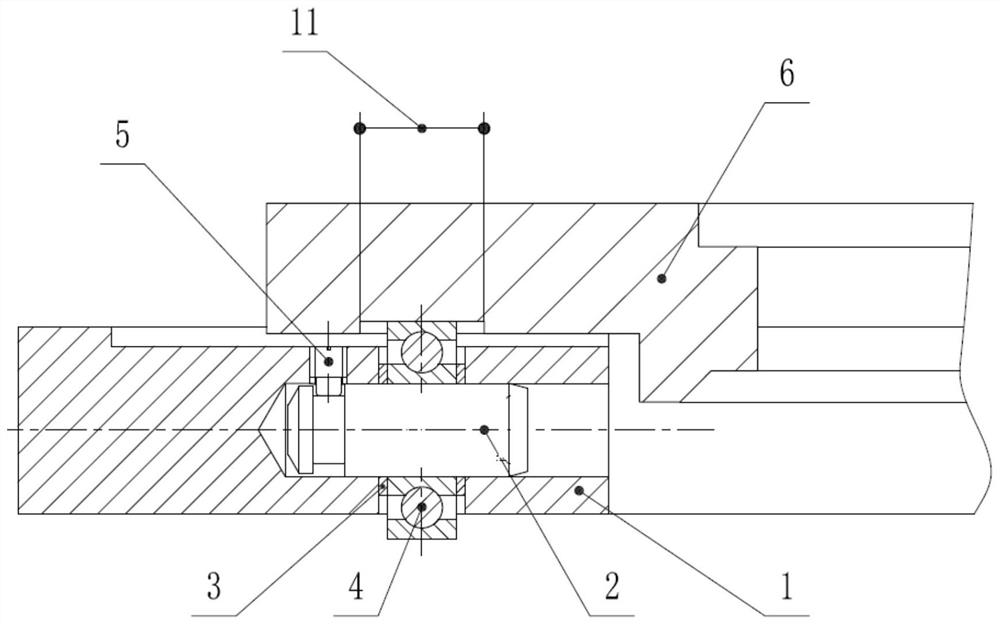

[0011] Such as figure 1 The turning tooling device for the intermediate shaft of the motor shown is composed of a supporting device and a rotating device. The rotating device is installed on the supporting device. The track of the rotating device is clamped on the deep groove ball bearing 4. The supporting device is a A sliding vehicle seat, the vehicle seat comprises a support vehicle 1, a shaft pin 2, a retaining piece 3, a deep groove ball bearing 4 and a set screw 5, the support vehicle 1 is a flat plate with a circular gap, and the support vehicle 1 outer end surface has a The first pin hole 7 fitted with the shaft pin 2 has a waist-shaped through hole 8 in the vertical position, and the deep groove ball bearing 4 is installed in the waist-shaped through-hole 8, and one side of the waist-shaped through-hole 8 has a There are threaded holes and are assembled with set screws 5, and the circular opening of the support car 1 has a second pin hole 9; the deep groove ball beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com