Gluing equipment control method and system

A technology of equipment control and control system, applied in the field of gluing, which can solve the problems of many uncontrollable factors in manual adjustment and the decrease of bonding effect, so as to ensure the amount of gluing, realize automatic air pressure adjustment, and improve the quality of gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

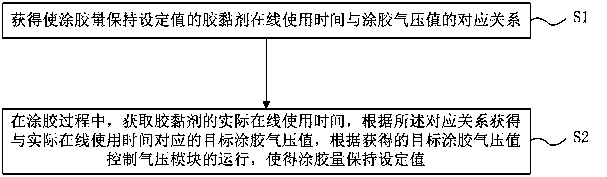

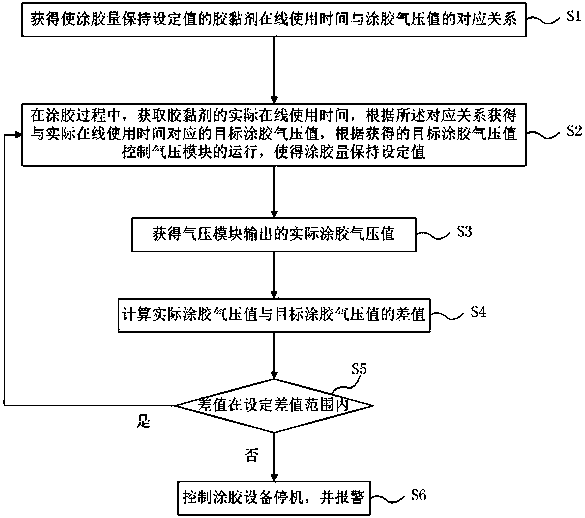

[0041] Embodiment 1. The gluing equipment control method of this embodiment specifically includes the following steps, see figure 1 shown.

[0042] Step S1: Obtain the corresponding relationship between the online use time of the adhesive and the pressure value of the glue application to keep the glue application amount at the set value.

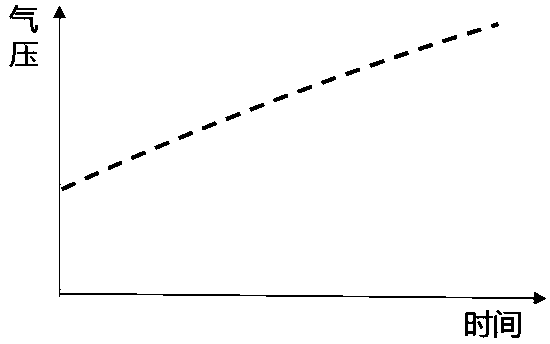

[0043] The online use time of the adhesive is counted from the time the adhesive is installed on the glue outlet module, that is, the time for the adhesive to be installed on the glue outlet module. The longer the time, the greater the viscosity of the adhesive. In order to ensure the adhesive The greater the amount, the greater the glue pressure required.

[0044] In this embodiment, this step specifically includes the following steps:

[0045] (11) Put the adhesive into the gluing module of the gluing equipment and start timing.

[0046] (12) After setting the time (such as 0.5 hours), adjust the operation of the air pressure module so ...

Embodiment 2

[0084] This embodiment proposes a control system for gluing equipment. The gluing equipment controls the amount of glue applied through the gluing air pressure output by its air pressure module. The control system mainly includes a corresponding relationship acquisition module, a time acquisition module, a control module, etc. , see Figure 5 shown.

[0085] The corresponding relationship obtaining module is used to obtain the corresponding relationship between the online use time of the adhesive and the pressure value of the glue applied to maintain the glue application amount at the set value.

[0086] The time acquisition module is used to acquire the actual online usage time of the adhesive during the gluing process.

[0087] The control module is used to obtain the target gluing air pressure value corresponding to the actual online use time according to the corresponding relationship, and control the operation of the air pressure module according to the obtained target g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com